Zhejiang YOUJI Machinery Technology Co., Ltd. has once again demonstrated its leadership in specialized, high-end valve inspection by delivering a custom-engineered valve test bench to the Weiming Environmental Protection Equipment Group. This project, designed specifically for a demanding, contaminant-free cleanroom environment, marks another significant milestone for YOUJI in providing solutions for the most critical industrial applications.

The new system is a core component of Weiming’s upgraded clean testing workshop, a facility dedicated to the manufacturing of specialized, corrosion-resistant valves. For engineering and procurement leaders in sectors like new materials, environmental treatment, and advanced manufacturing, this collaboration highlights YOUJI’s unique capability to engineer and deliver testing solutions that meet the dual challenge of extreme durability and absolute cleanliness.

A Strategic Partnership with a Leader in Environmental Technology

Weiming Environmental Protection Equipment Group, a wholly-owned subsidiary of the Shanghai Stock Exchange-listed Zhejiang Weiming Environment Protection Co., Ltd. (SSE: 603568), is a major force in environmental governance, high-end equipment manufacturing, and new materials development. As a recipient of accolades such as “Backbone Enterprise of China’s Environmental Protection Industry,” their commitment to quality and technological advancement is uncompromising.

Their choice of YOUJI for this critical cleanroom upgrade underscores the trust in our ability to provide equipment that aligns with their stringent manufacturing standards. This partnership will be pivotal in advancing Weiming’s production of high-performance, corrosion-resistant valves.

Engineered for Purity and Performance

The custom-designed test bench provides a suite of technical advantages tailored for testing specialized corrosion-resistant valves in a cleanroom environment:

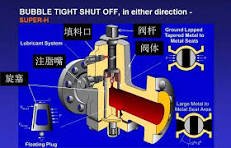

- Broad Valve Compatibility: Provides comprehensive testing for a variety of corrosion-resistant valve types, including gate, ball, and globe valves.

- Extensive Operational Range: Supports a wide spectrum of valve sizes (DN15-DN600) and can handle pressures from 1.6 to 48MPa.

- Contamination-Free Digital Testing: Implements a fully digital management system for high-pressure gas tightness and strength tests within a clean, dust-free protocol, ensuring the integrity of the valves is never compromised.

- Smart Factory Ready: The system is pre-configured for seamless integration with MES (Manufacturing Execution System), facilitating Weiming’s intelligent factory objectives.

The Preferred Choice for Industry Innovators

YOUJI’s reputation is built on leveraging new materials and intelligent, IT-integrated solutions to solve complex challenges. Our products undergo continuous iteration, incorporating advanced materials for critical components and deep integration of smart control technology. This forward-thinking approach has earned the confidence of a growing list of distinguished domestic and international clients.

Our client portfolio features industry leaders such as Fangzheng Valve, Fangyuan Valve, Xi’an Pump and Valve General Factory, Shenjiang, and Lianggu, and continues to expand into high-growth sectors like new energy and marine engineering, reflecting a consistent rise in our export orders.

Certified Excellence, Comprehensive Service

At YOUJI, we provide an integrated “Business-Technical-After-Sales” service framework to ensure a seamless client experience. Our core technological leadership is validated by our inclusion in the prestigious Zhejiang Province’s list of “First Set” Major Technical Equipment in Advanced Manufacturing. With numerous invention patents and software copyrights, and as a key participant in setting industry and group standards, our expertise is well-documented. We are a qualified supplier to energy giants such as Sinopec, CNPC, and CNOOC.

Moving forward, Zhejiang YOUJI will continue to pioneer advancements in the high-end valve inspection field, delivering smarter and cleaner solutions to our global clientele and leading the intelligent, contamination-free transformation of the valve testing industry.