1. General Valve Test Bench (Valve Testing Equipment, Valve Pressure Testers, Valve Testing Machines)

Application: Suitable for most common valve types, including ball valves, gate valves, and globe valves.

Main Test Items:

Sealing Test: Ensures the sealing performance of valves in both open and closed positions.

Strength Test: Verifies the mechanical strength of valves at rated pressure.

Flow Characteristics: Evaluates the flow coefficient and resistance characteristics of valves.

Actuation Test: Detects the operating flexibility and required torque of valves.

2. High-Pressure Valve Test Bench (Valve Testing Equipment, Valve Pressure Testers, Valve Testing Machines)

Application: Designed for high-pressure environments, suitable for high-pressure regulating valves, safety valves, and more.

Main Features:

High-pressure sealing technology ensures reliable operation under harsh conditions.

High-temperature-resistant materials accommodate high-temperature operation requirements.

3. Vacuum Valve Test Bench

Application: Used to test valves in vacuum environments, such as butterfly valves and ball valves in vacuum systems. Main Functions:

Test vacuum tightness and ensure reliability under extremely low pressures.

Analyze performance under high or low temperature conditions.

4. Fire Test Bench

Purpose: Evaluate valve performance under fire conditions, suitable for fields such as petrochemicals and nuclear power.

Features: Equipped with fire-resistant materials and structural design, it simulates real-world fire environments for testing.

5. Low-Temperature Test Bench

Purpose: Designed for extreme cold conditions, it tests valves in cryogenic applications such as liquefied natural gas (LNG).

Main Tests:

Low-Temperature Tightness: Ensures leak-free performance at extremely low temperatures.

Material Properties: Evaluates mechanical properties and impact resistance of materials at low temperatures.

6. Pneumatic/Hydraulic Valve Test Bench

Purpose:

Pneumatic valves: Test control accuracy, actuation time, and reliability.

Hydraulic valves: Evaluate hydraulic actuation start-up time, closing torque, and tightness, while also detecting leaks.

7. Flow Characteristics Test Bench

Purpose: Detailed analysis of valve flow characteristics and control performance.

Key Metrics:

Flow Curve: Plots and analyzes the relationship between valve diameter and flow rate. Resistance Calculation: Evaluates the valve’s impact on system flow.

8. Leak Detection Test Bench

Purpose: High-precision valve leakage detection, suitable for high-pressure or vacuum environments.

Features: Utilizes advanced sensors and testing methods (such as the bubble method and infrared imaging) for precise measurement.

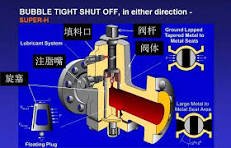

9. Specialized Test Bench for Ball Valves/Butterfly Valves

Purpose: Designed for specific valve types to ensure comprehensive testing.

Test Content:

Rotary sealing and torque for ball valves.

Opening angle and sealing surface wear for butterfly valves.

10. Modular Multifunctional Test Bench

Purpose: Highly comprehensive, configurable with a variety of test modules.

Features: Suitable for various valve testing needs, improving efficiency and reducing operating costs.

Additional Types to Consider

Chemical Leakage Test Bench:

Test media are corrosive or special liquids to ensure the durability of valve rings and seals.

Radiation Shielding Test Bench:

Used in nuclear industry environments to evaluate valve performance changes under high radiation doses. Wear Test Benches:

Simulate high-wear conditions to test the service life of valve components (such as valve seats and valve cores).

Mobile/Portable Test Benches:

On-site equipment suitable for remote or temporary testing needs.

Summary

Selecting the appropriate valve test bench (valve inspection equipment, valve pressure tester, valve testing machine) requires consideration of the test media type, pressure, temperature, and safety requirements. Proper use of these devices can effectively ensure valve performance reliability and ensure safe and efficient operation in various industrial environments.