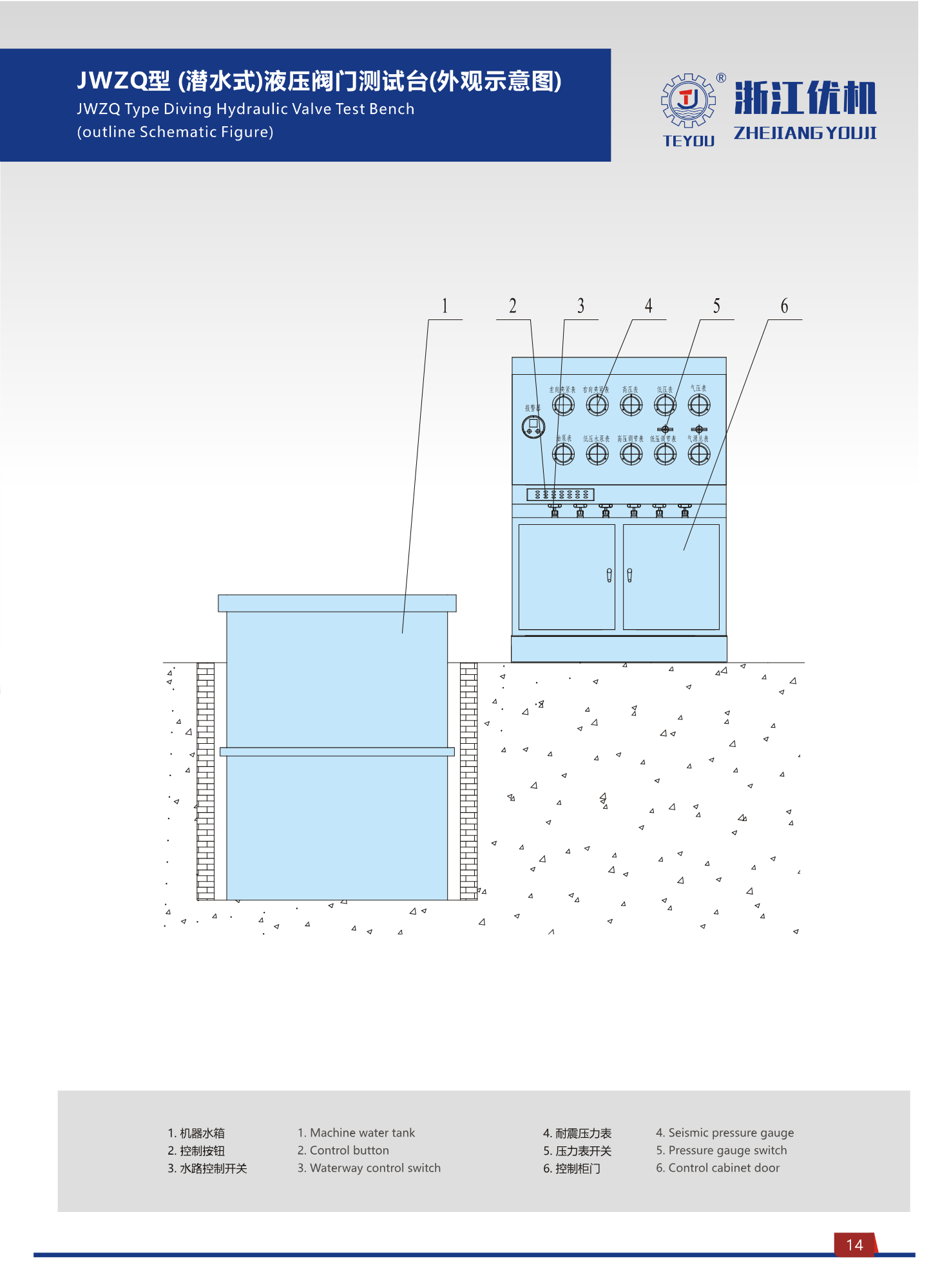

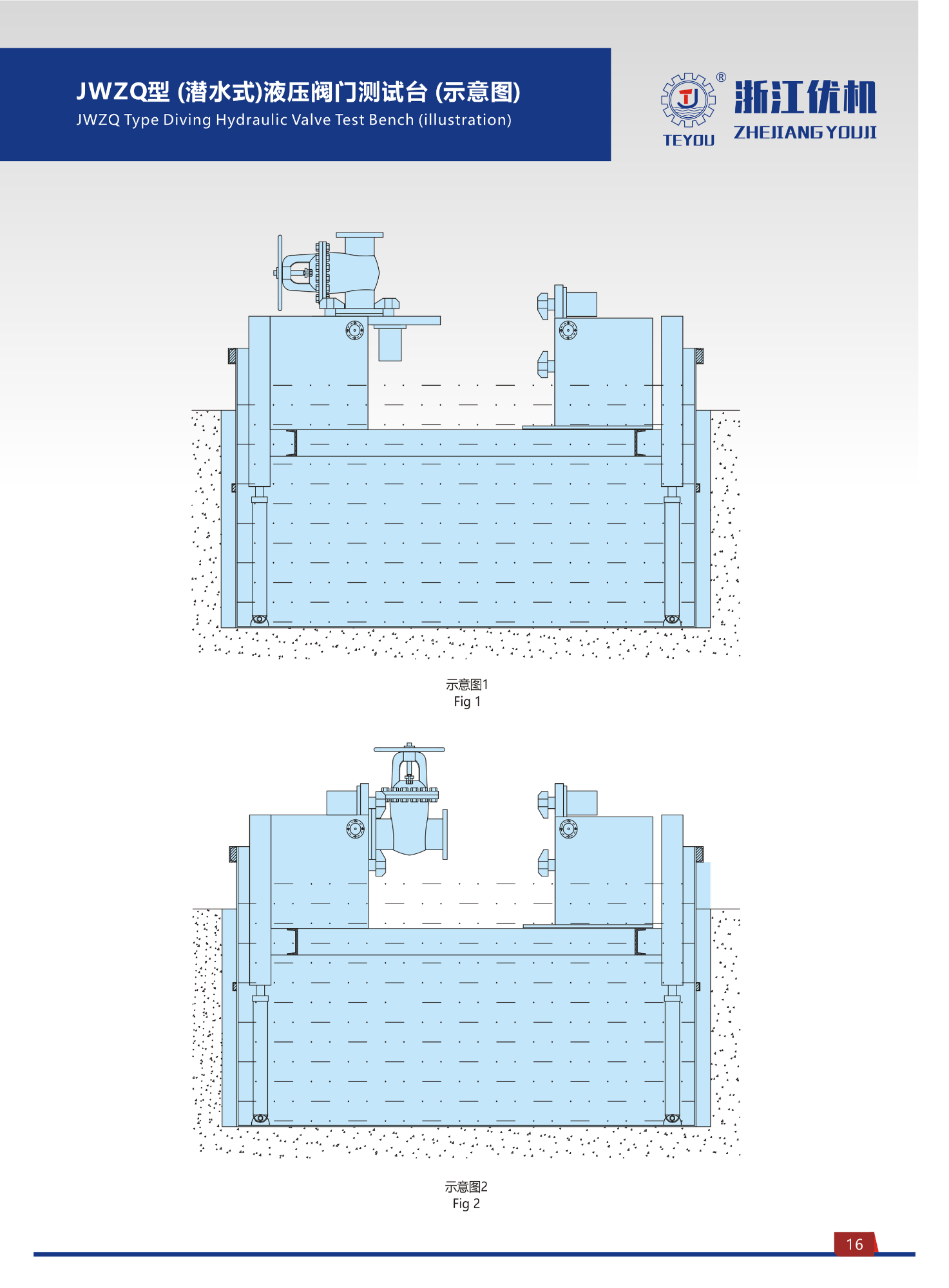

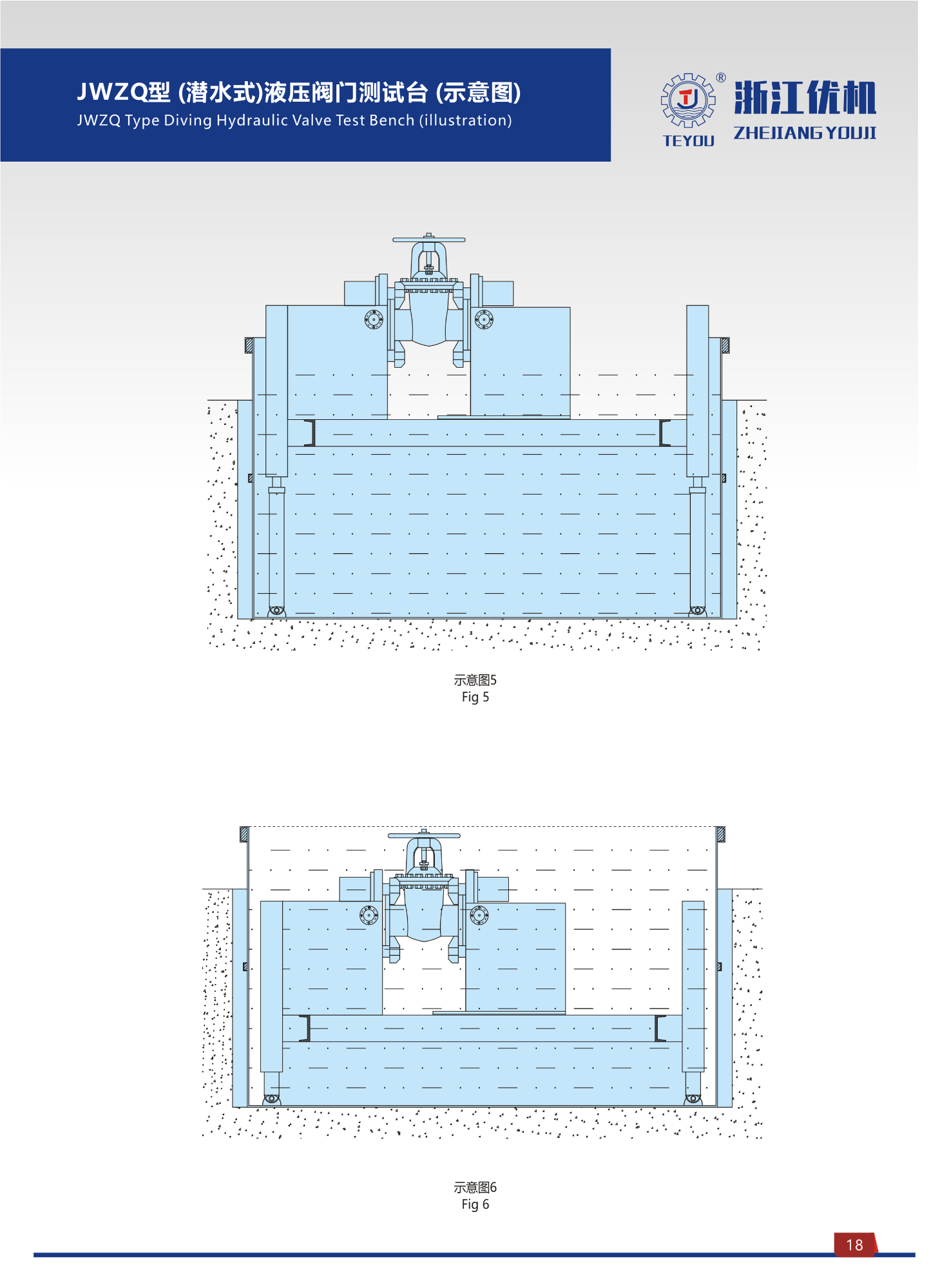

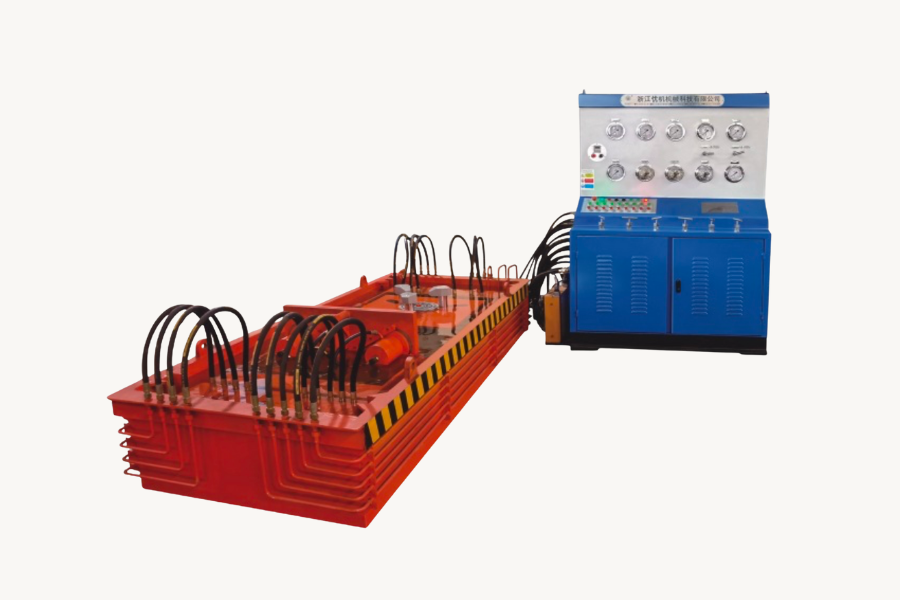

The JWZQ Series is a specialized hydraulic valve test bench featuring a submersible design for unparalleled visual leak detection. For critical applications where zero leakage is mandatory, this system allows the valve under test to be fully immersed in a built-in water tank. This process enables operators to easily and accurately identify any bubbles indicating a seat leak, providing definitive, visual proof of valve performance.

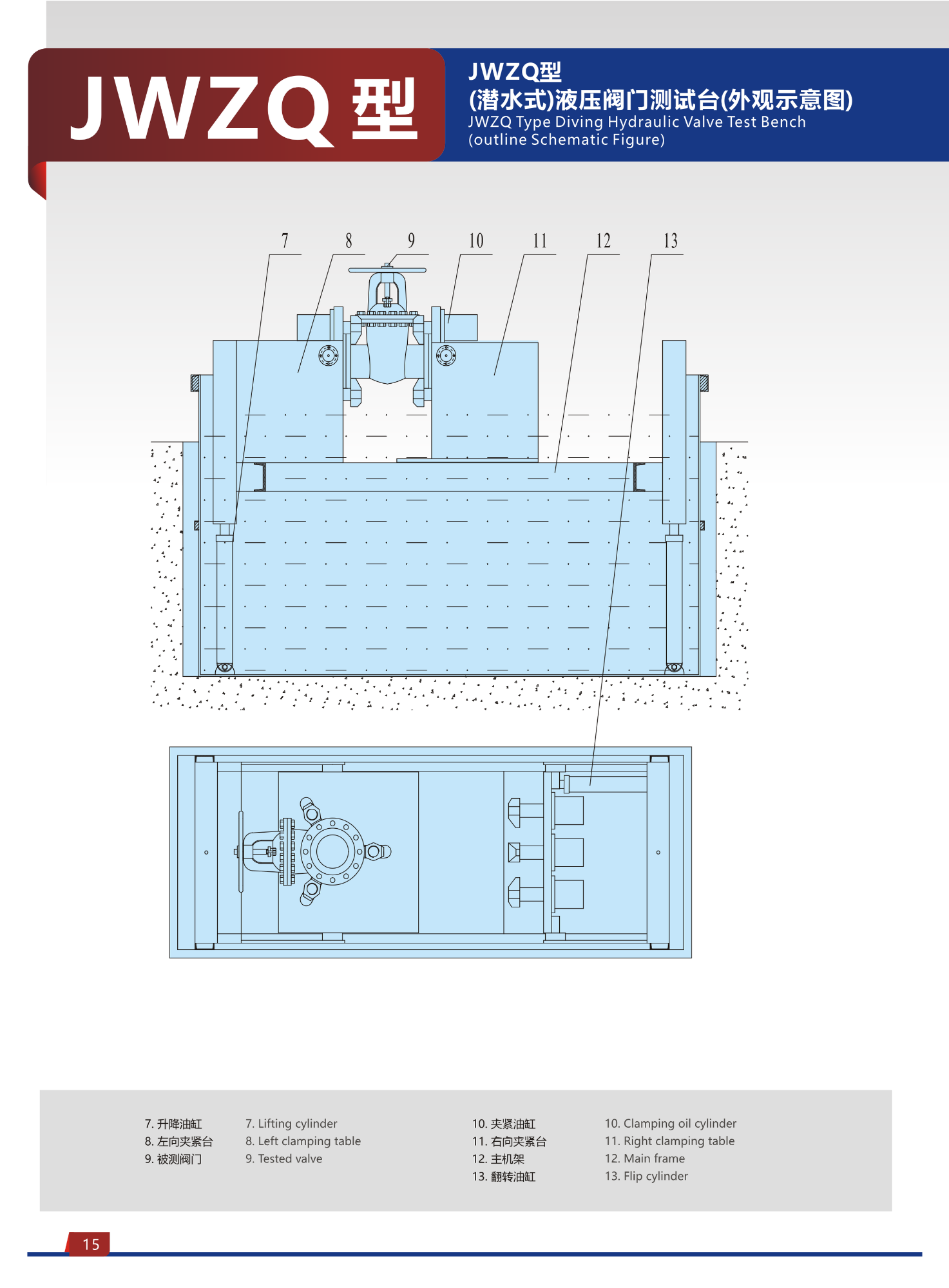

Engineered with our patented clamping technology, the JWZQ series ensures test integrity by securing the valve without applying external stress to the valve body. It is a complete, all-in-one solution for valve manufacturers and service centers demanding the highest standards of quality assurance, fully compliant with API 598 and GB/T 13927.

Key Features

- Submersible Design for Visual Leak Detection: The system’s primary feature is a work table that lowers the test piece into a water tank, allowing for direct visual inspection of bubble leakage during air tightness tests.

- Patented Clamping Technology: Utilizes a hydraulic jaw clamping system (Patent No. ZL201610260566.7) that holds the valve flange from behind, ensuring no external forces can compromise the accuracy of test results.

- Full Standards Compliance: Rigorously designed to meet and exceed the requirements of GB/T 13927-2022, GB/T 26480-2011, JB/T 14310-2022, and API 598-2009.

- 90° Tilting for Comprehensive Testing: The clamping mechanism can be flipped 90 degrees, providing optimal positioning and flexibility for various test procedures, especially for gas testing.

- Energy-Efficient Hydraulics: Incorporates an automatic high-pressure unloading function, which minimizes oil temperature, extends the lifespan of hydraulic components, and reduces energy consumption.

- Integrated Safety Systems: Equipped with a pressure interlock system that prevents operation until all residual pressure is released, alongside a safety pressure protection device to safeguard both the operator and the valve.

- Optional PC Data Acquisition: Can be upgraded with a computer-based control system for digital monitoring, data logging, and automatic generation of test reports.

Technical Specifications

| Specification | Value |

|---|---|

| Model | JWZQ Series |

| Applicable Diameter | DN15 – DN600 / NPS 1 1/2” – 24” |

| Pressure Range | PN1.6 – 48 MPa / Class 150 – 2500 lb |

| Test Medium | Water, Air, Oil (User-selectable) |

| Clamping Method | Hydraulic Jaw Clamping (Submersible) |

| Applicable Valve Types | Gate, Globe, Ball, Check Valves, and other flanged valves |

| Control System | Hydraulic Drive, PLC Control, Push-Button Operation |

| Body Material | High-Strength Structural Steel (Q325A) |

| Patents & Standards | National Patent (ZL201610260566.7), API 598, GB/T 13927 |

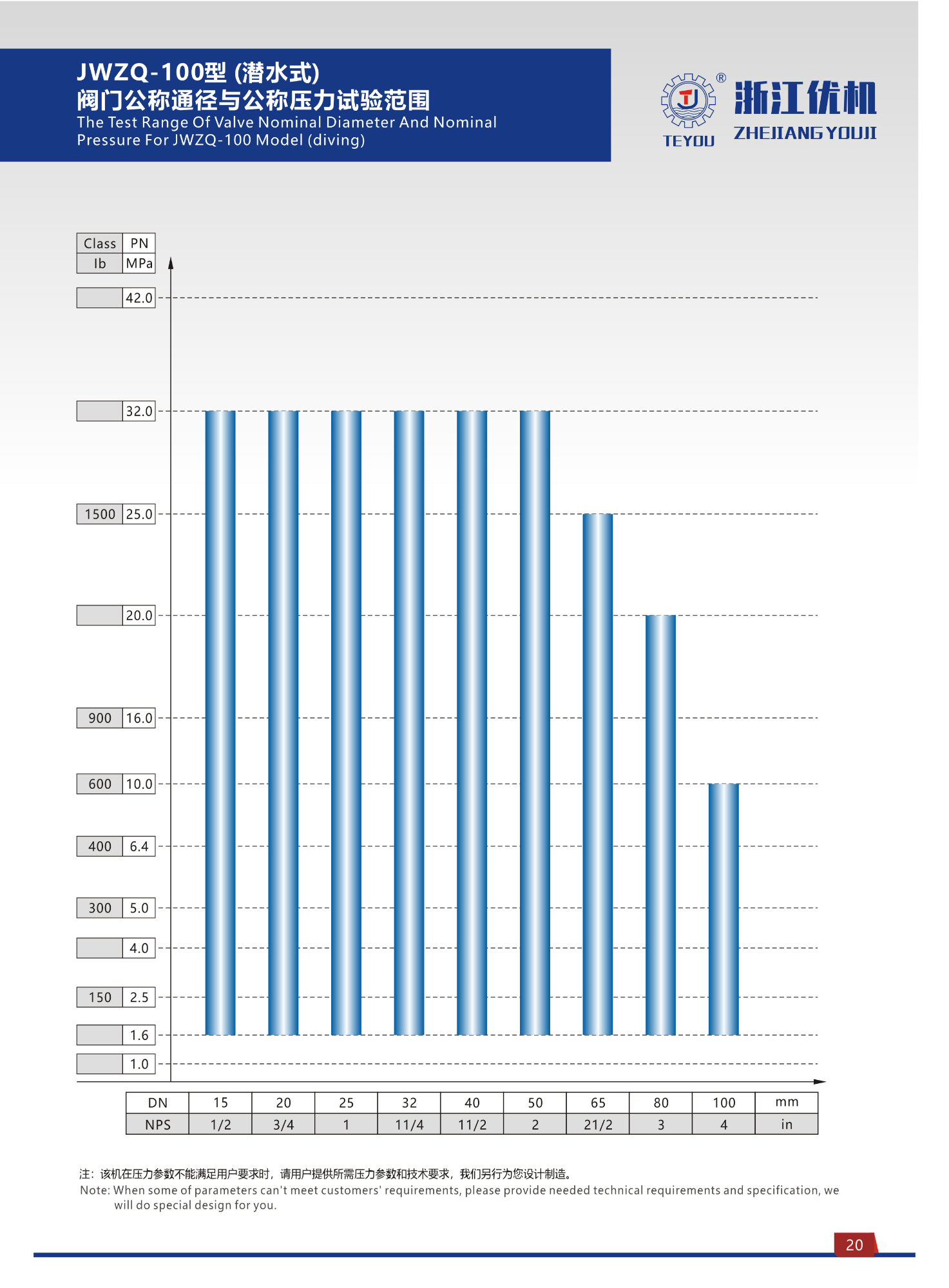

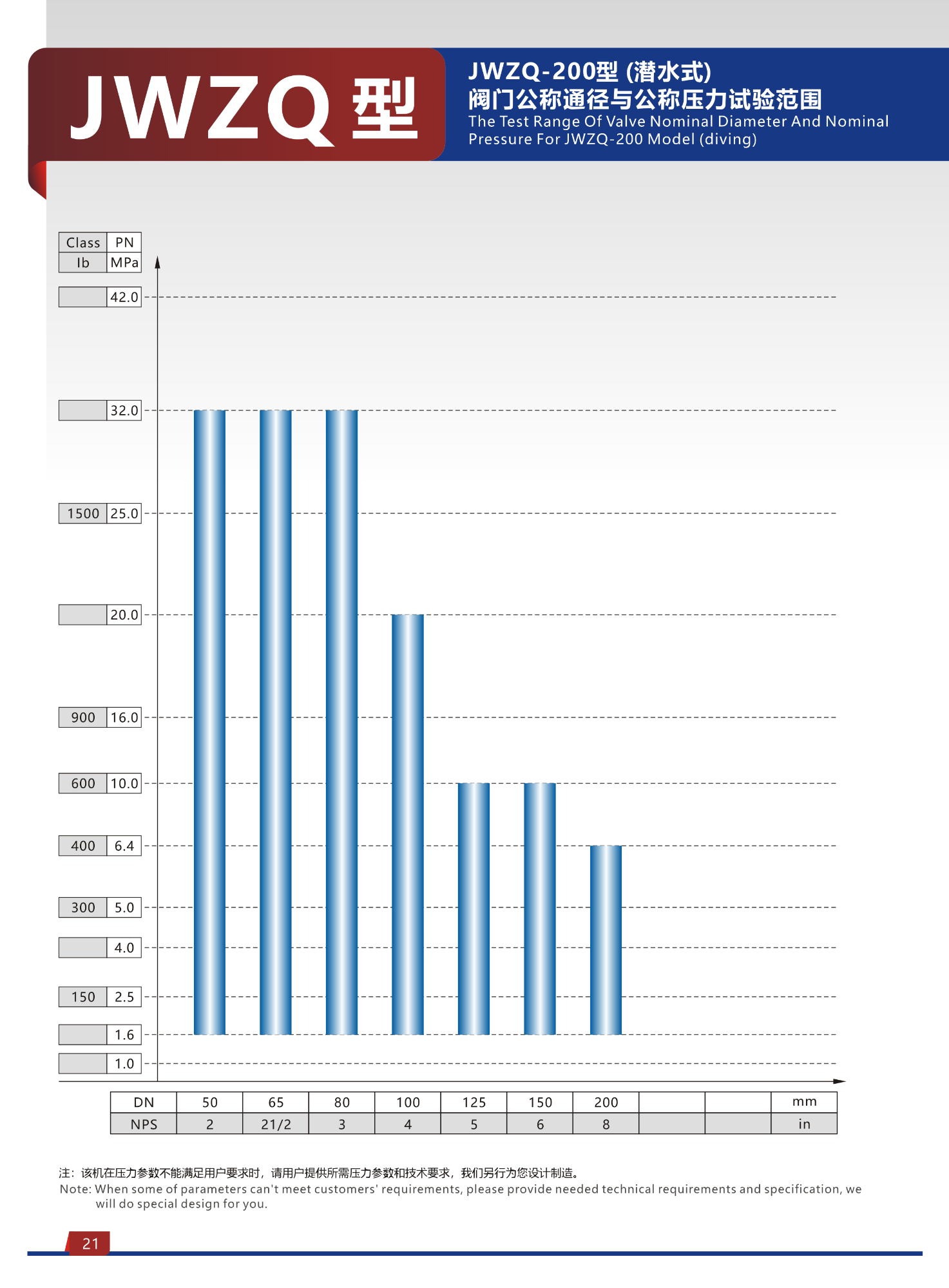

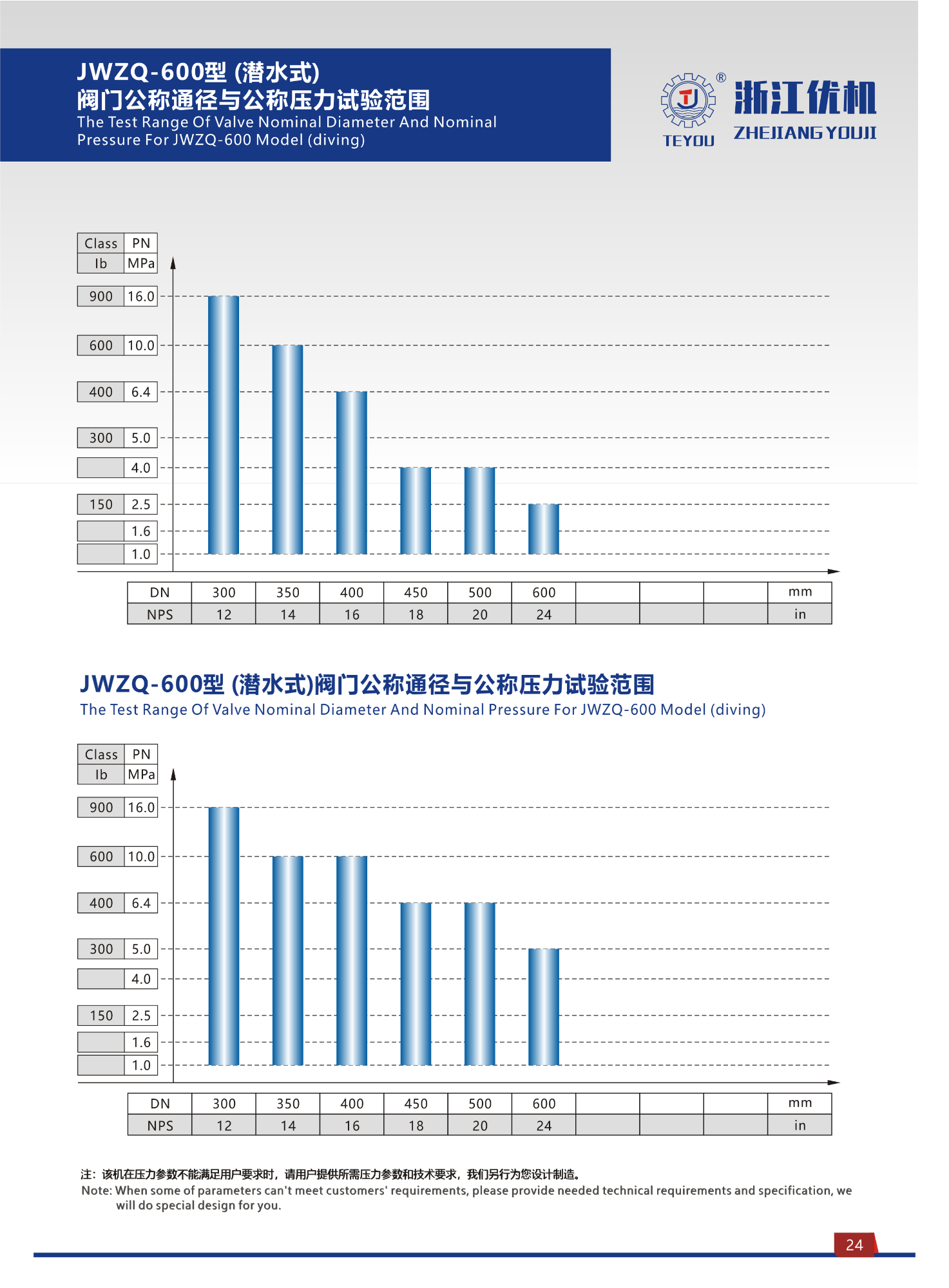

| Type Specification | JWZQ-100 | JWZQ-200 | JWZQ-300 | JWZQ-400 | JWZQ-500 | JWZQ-600 |

|---|---|---|---|---|---|---|

| Allowable test valve bore (DN/mm) | 15-100 | 50-200 | 80-300 | 150-400 | 250-500 | 300-600 |

| Nominal pressure (PN/MPa) | 1.6-32 | 1.6-32 | 1.6-32 | 1.6-32 | 1.0-16 | 1.0-16 |

| Moveable distance – Max. (mm) | ≤700 | ≤850 | ≤1100 | ≤1200 | ≤1400 | ≤1500 |

| Moveable distance – Min. (mm) | ≥200 | ≥250 | ≥280 | ≥350 | ≥450 | ≥450 |

| Axial travel (mm) | ≤60 | ≤70 | ≤85 | ≤105 | ≤105 | ≤105 |

| Radial travel (mm) | ≤120 | ≤160 | ≤200 | ≤240 | ≤250 | ≤230 |

| Pressure adjustment range (MPa) | 0-6.3 | 0-6.3 | 0-6.3 | 0-6.3 | 0-6.3 | 0-6.3 |

| Flow (L/min) | 16 | 16 | 16 | 25 | 25 | 40 |

| High pressure (pressurized) (MPa) | 3.0-31.5 | 3.0-31.5 | 3.0-31.5 | 3.0-31.5 | 3.0-31.5 | 3.0-31.5 |

| Pressure for oil pump (MPa) | 0-5.0 | 0-5.0 | 0-5.0 | 0-5.0 | 0-5.0 | 0-5.0 |

| Voltage (V) | 380 | |||||

| Frequency (Hz) | 50 | |||||

| Motor Power (KW) | 2.2 | 2.2 | 2.2 | 3 | 3 | 5.5 |

| Pole (P) | 6 | |||||

| Overall dim. L (mm) | 2830 | 2910 | 3350 | 3650 | 3900 | 4120 |

| Overall dim. B (mm) | 1050 | 1130 | 1340 | 1540 | 1570 | 1630 |

| Overall dim. H (mm) | 1300 | 1700 | 1800 | 2200 | 2600 | 2800 |

| Weight (kg) | 2680 | 3580 | 4800 | 7200 | 7900 | 8800 |

Application Areas

The JWZQ submersible valve test bench is the definitive testing solution for industries where valve integrity is paramount:

- Valve Manufacturing

- Oil & Gas

- Petrochemical Industry

- Nuclear Power

- Chemical Processing

- Valve Repair & Maintenance (MRO)

Competitive Advantages

- Unmistakable Leak Detection: The submersible design eliminates the ambiguity of pressure drops by providing clear, visual evidence of leaks. This is the most reliable method for verifying seat tightness.

- Guaranteed Test Integrity: Our patented jaw clamping system ensures that the test measures the valve’s performance alone, without any influence from external clamping forces.

- Certified & Compliant: Build confidence with your customers by certifying your valves on equipment that is fully compliant with the most stringent international testing standards.

- Integrated & Efficient Design: The JWZQ is an all-in-one system with integrated hydraulics, high/low-pressure pumps, and a media circulation system, designed for seamless and efficient workflow.

Support & Service

is dedicated to maximizing your operational uptime and testing accuracy. We offer complete support including:

- Installation guidance, including foundation/pit requirements.

- Comprehensive operator training.

- Responsive after-sales technical support and spare parts.

Discover the Certainty of Visual Leak Detection

Leave no doubt about your valve’s performance. Contact our technical team to learn how the JWZQ submersible test bench can enhance your quality control process and to receive a customized quote.