Description

Precision Testing for Industrial Valve Integrity and Performance

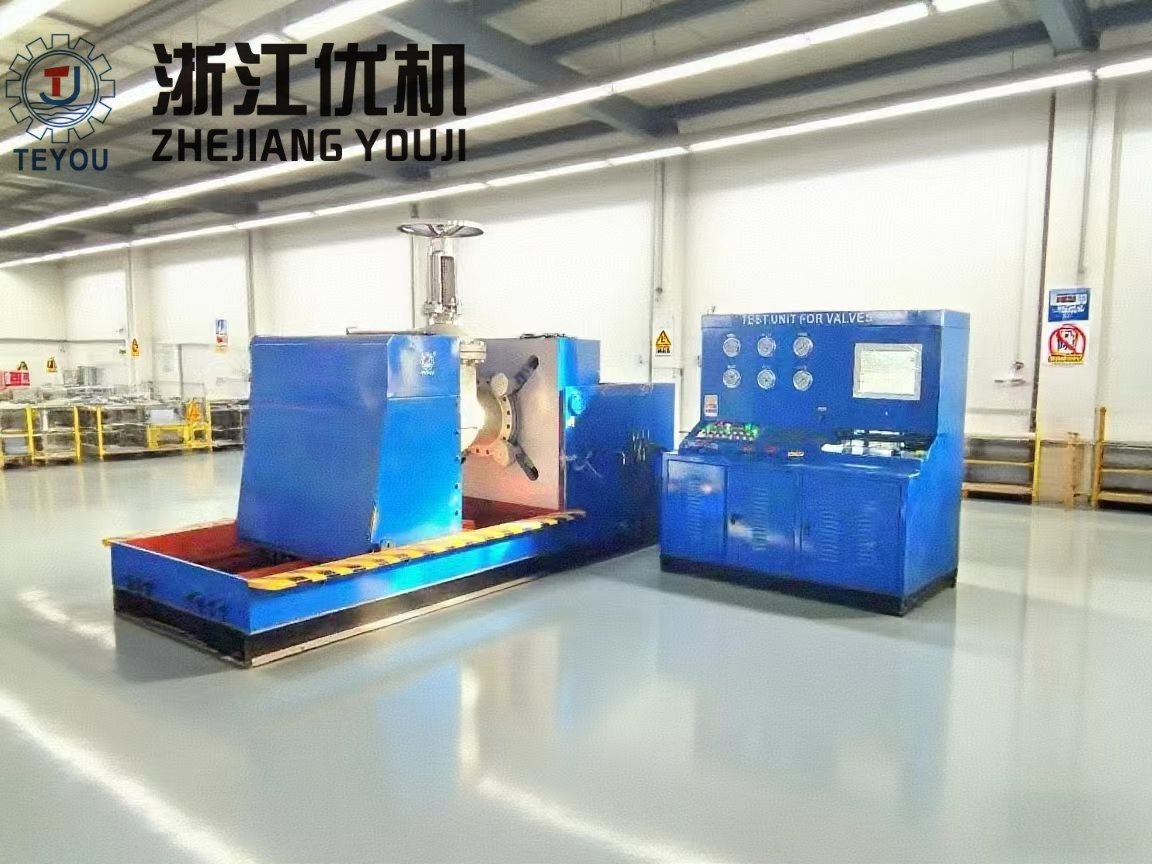

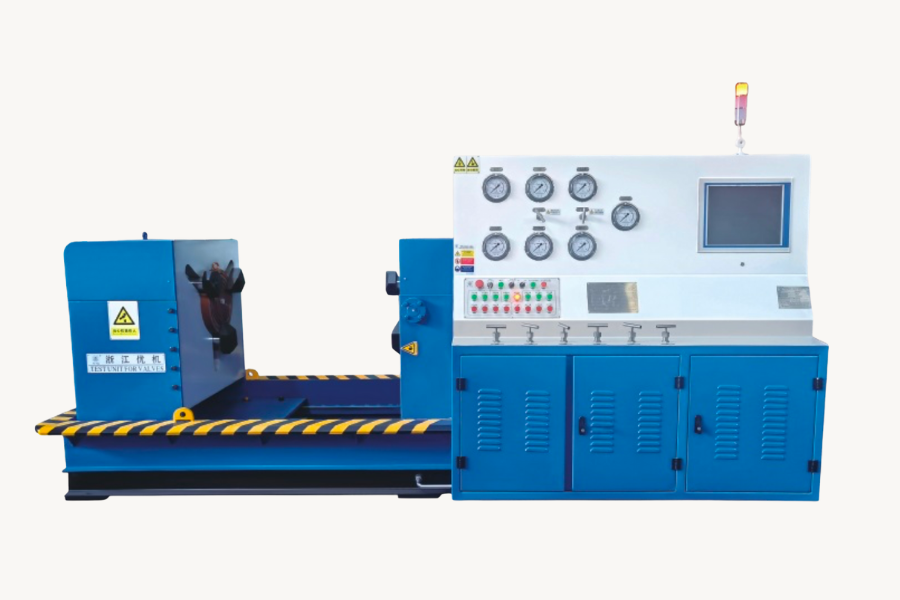

The YOUJI JWZ Type Hydraulic Valve Test Stand is an advanced testing system engineered for comprehensive performance evaluation of flanged valves. Integrating mechanical, hydraulic, and electronic control systems, this test bench provides reliable and efficient strength, sealing, and leakage tests. Developed in strict accordance with international standards like GB/T 13927 and API 598, and holding national patent (ZL2016 1 0240324.1), the JWZ series is the ideal valve testing equipment for manufacturers and service providers in critical industries.

Key Features

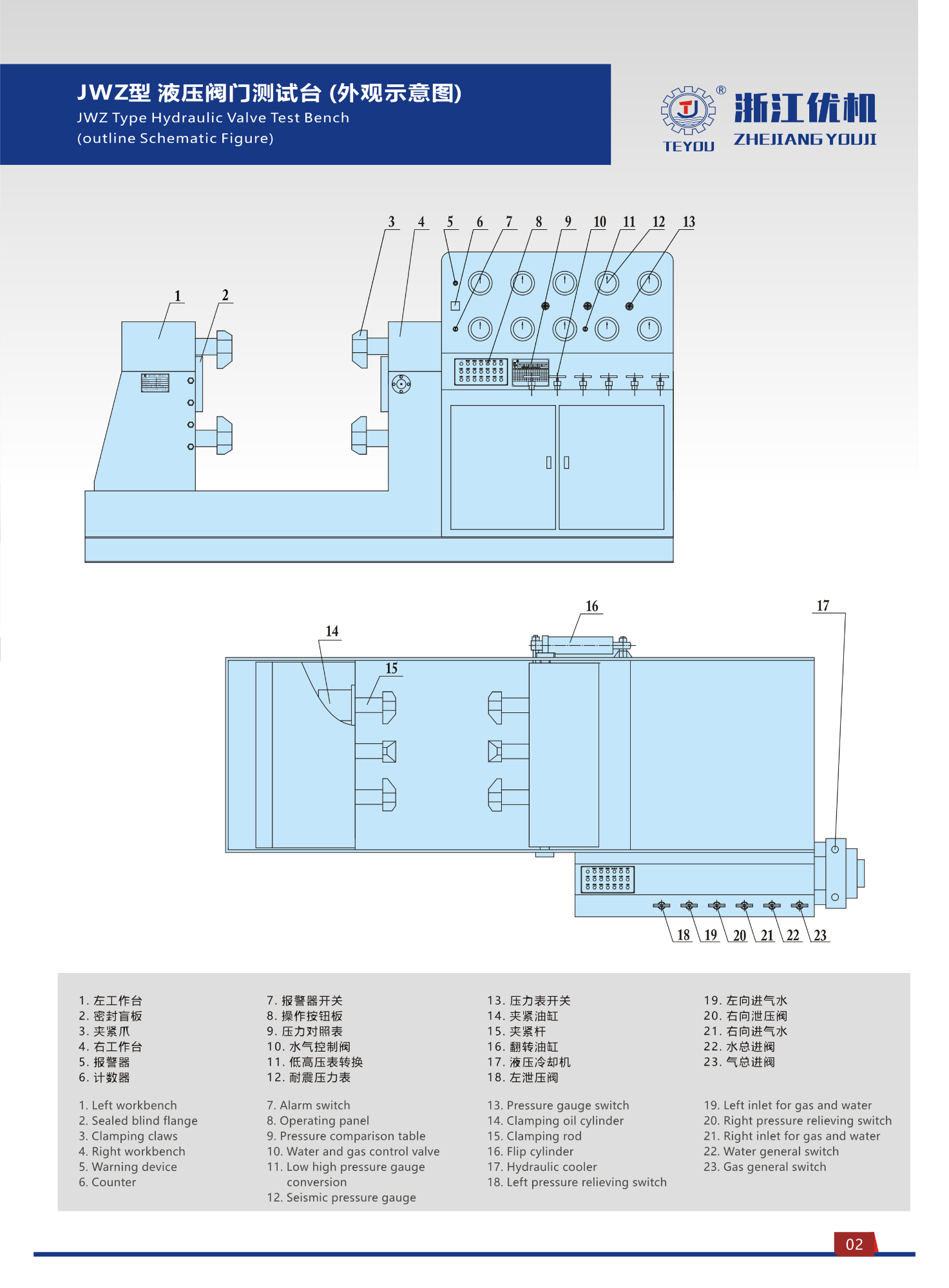

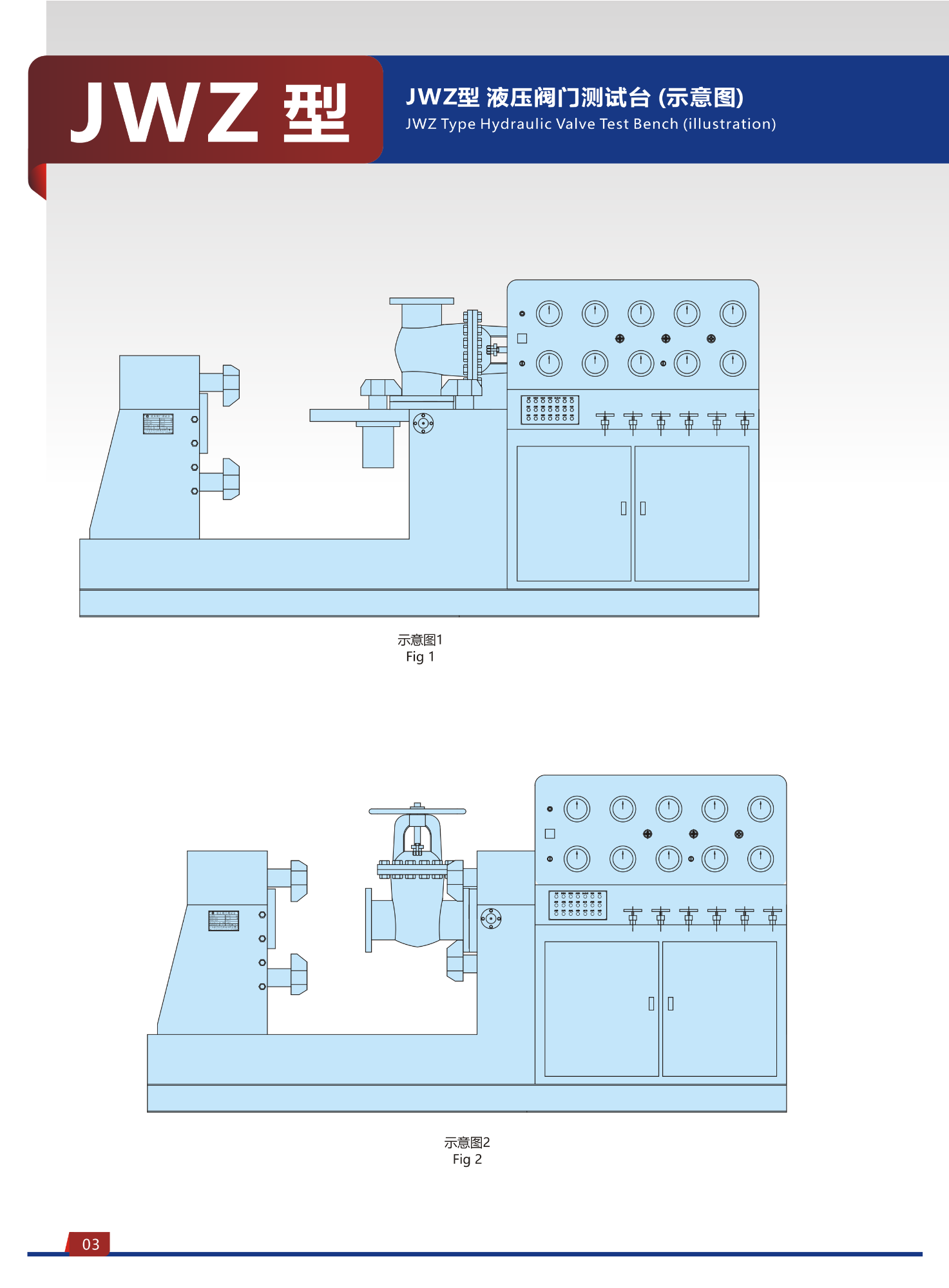

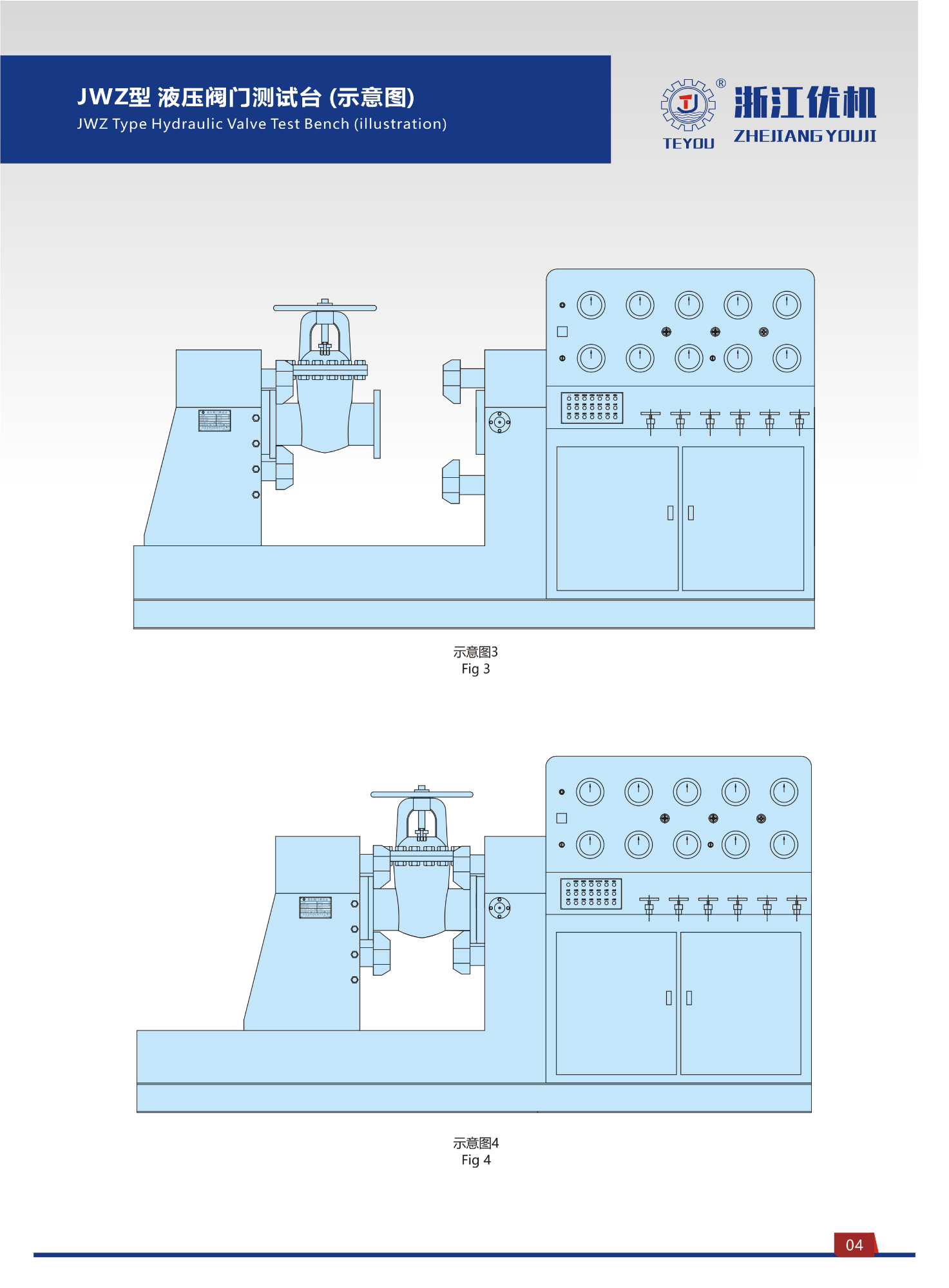

- Patented Claw Clamping System: Utilizes a hydraulic claw mechanism to grip the valve flange from the back. This method ensures uniform force distribution and eliminates external stress on the valve body, guaranteeing that test results are accurate and unaffected by the clamping process.

- Compliance with International Standards: Designed and manufactured to meet the rigorous requirements of GB/T 13927-2022, API 598-2009, and other key industry standards, ensuring your testing procedures are certified and reliable.

- 90° Tilting for Air Seal Testing: The work table can be tilted 90 degrees, providing an optimal setup for performing air (pneumatic) seal tests with enhanced visibility and accuracy.

- Integrated Hydraulic & Control System: Features a self-contained system with high and low-pressure water pumps, media circulation, and a choice of control modes (PLC computerized, push-button). The automated process significantly improves work efficiency and reduces manual labor.

- Advanced Safety Protection: Equipped with a hydraulic automatic unloading system and pressure interlocks. The system prevents operation under high residual pressure, ensuring operator safety and extending the equipment’s service life.

- Optional Computerized Data Management: Can be configured with a PC-based data acquisition and management system to record, save, and print detailed test reports, providing full traceability for quality control.

Technical Specifications

| Specification | Value |

| Model | JWZ Type Hydraulic Valve Test Stand |

| Applicable Valve Diameter | DN15 ~ DN1200 (NPS 1″ ~ 28″) |

| Maximum Clamping Pressure | PN1.6 ~ 48.0 MPa (Class 150 ~ 2500 lb) |

| Test Media | Water, Air, Oil (User-selectable) |

| Applicable Valve Types | Gate Valves, Globe Valves, Ball Valves, Check Valves, etc. |

| Connection Type | Flanged End Valves |

| Drive & Operation | Hydraulic Drive, PLC Computer Control, Push-Button Control |

| Body Material | High-Strength Carbon Steel (Customizable) |

| Certifications | National Patent, New Product Certificate |

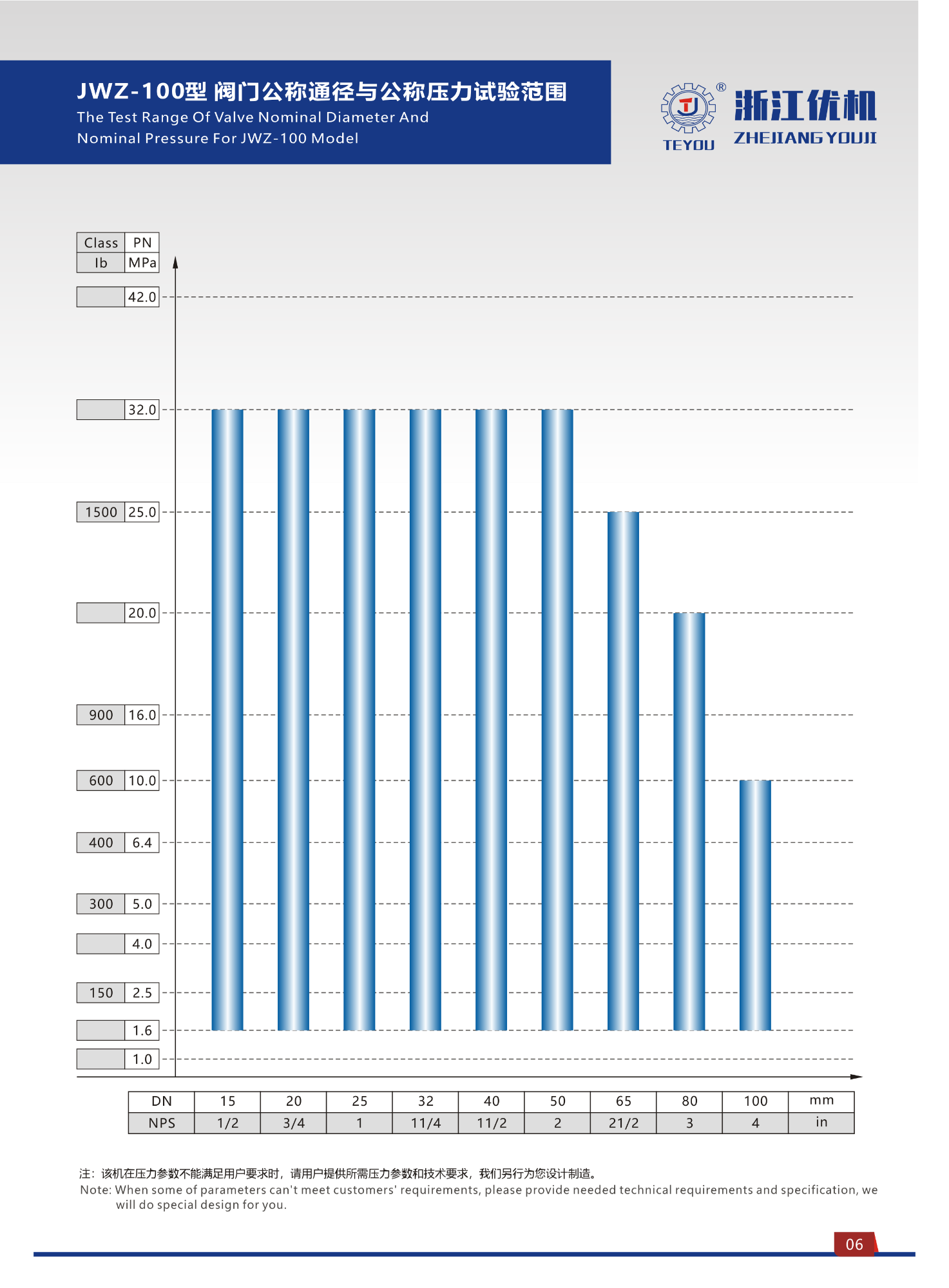

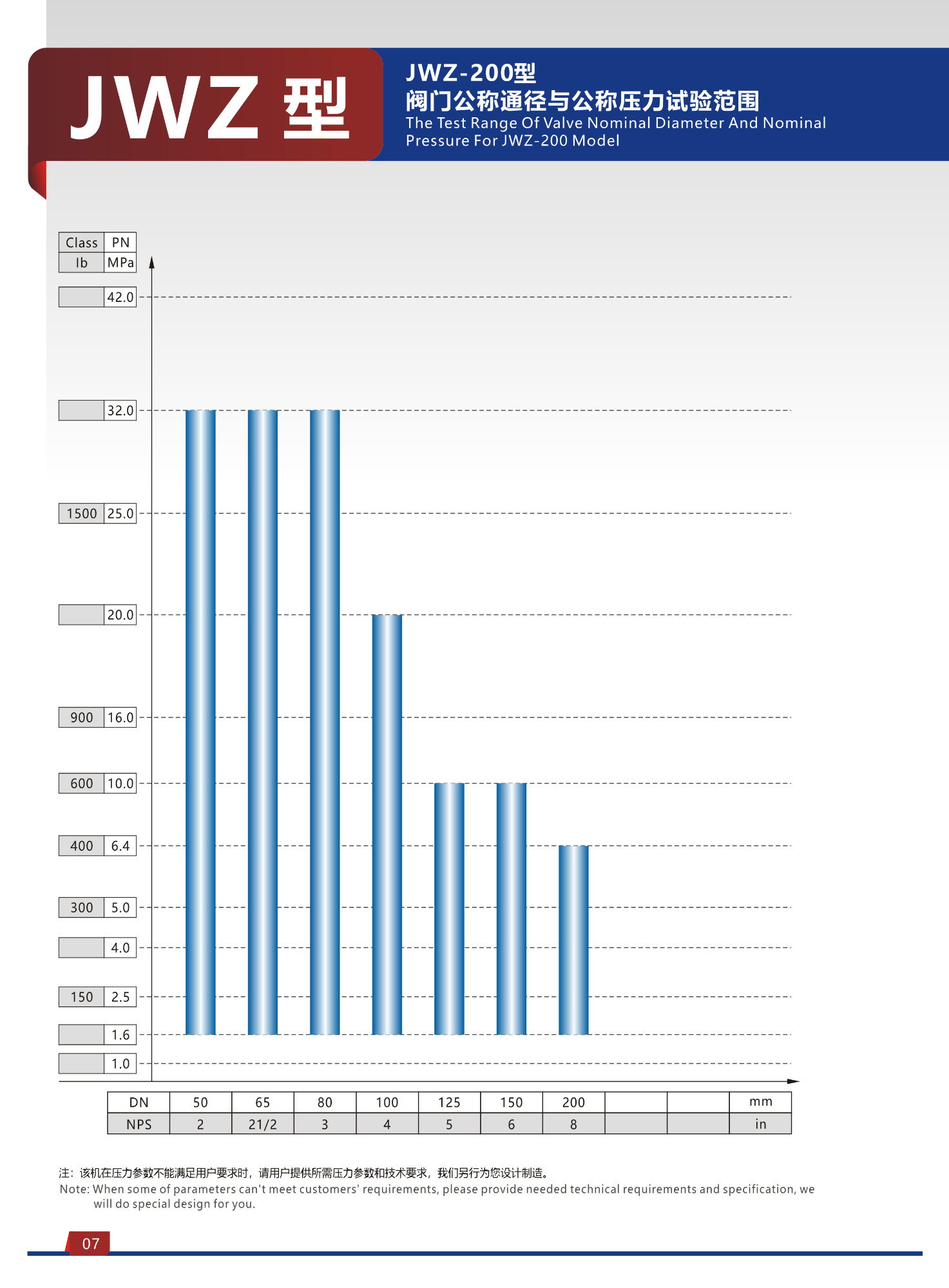

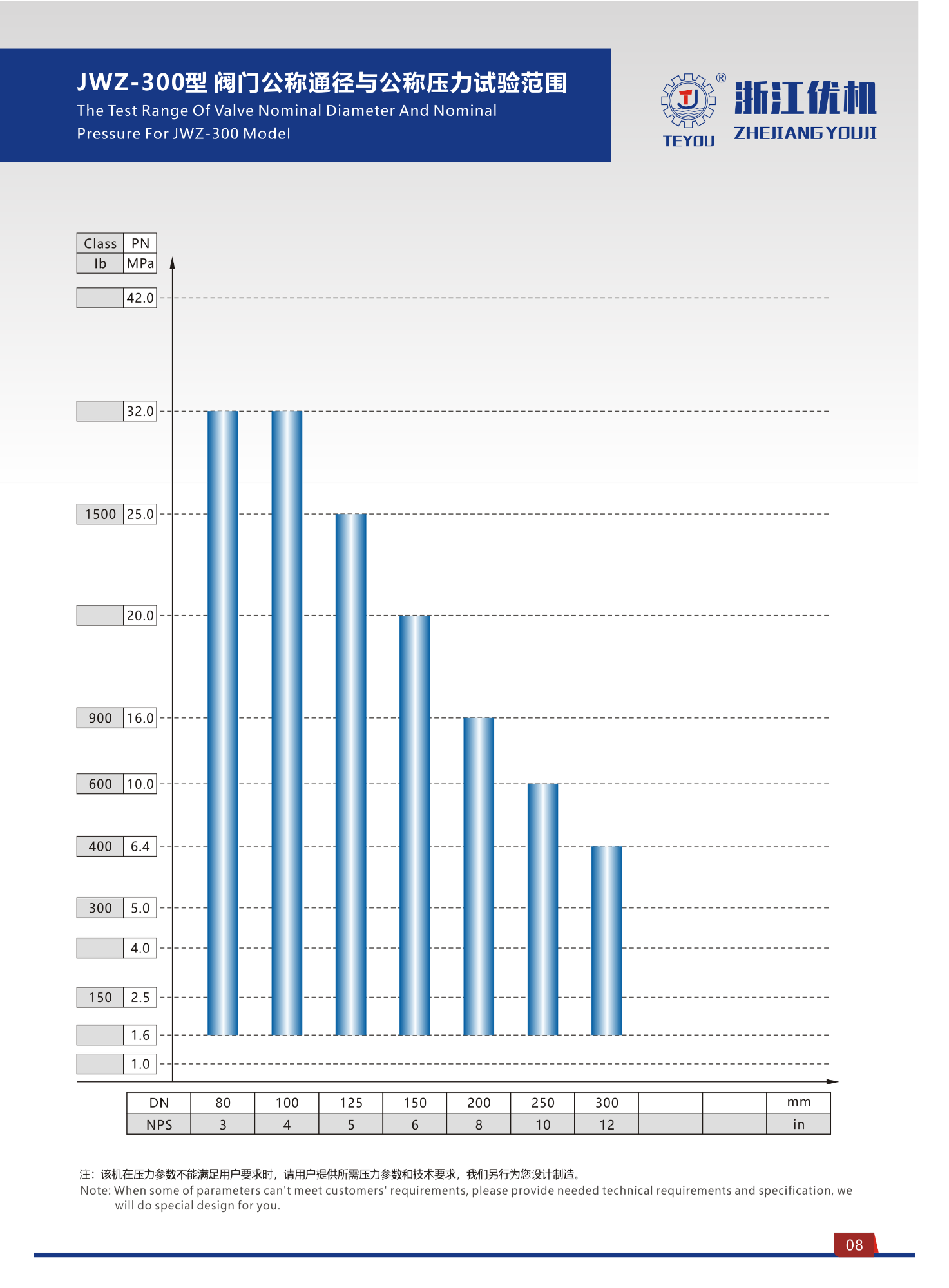

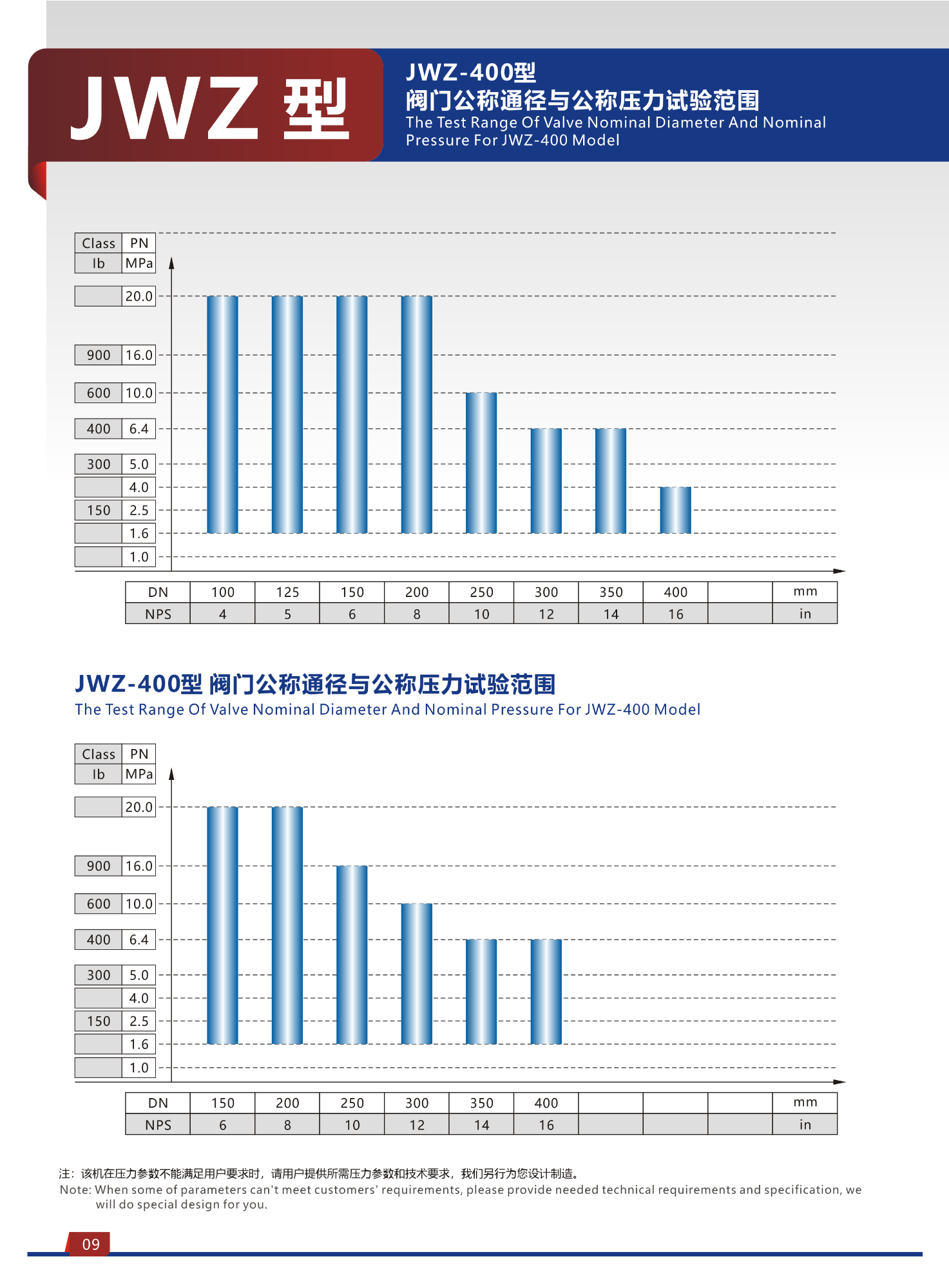

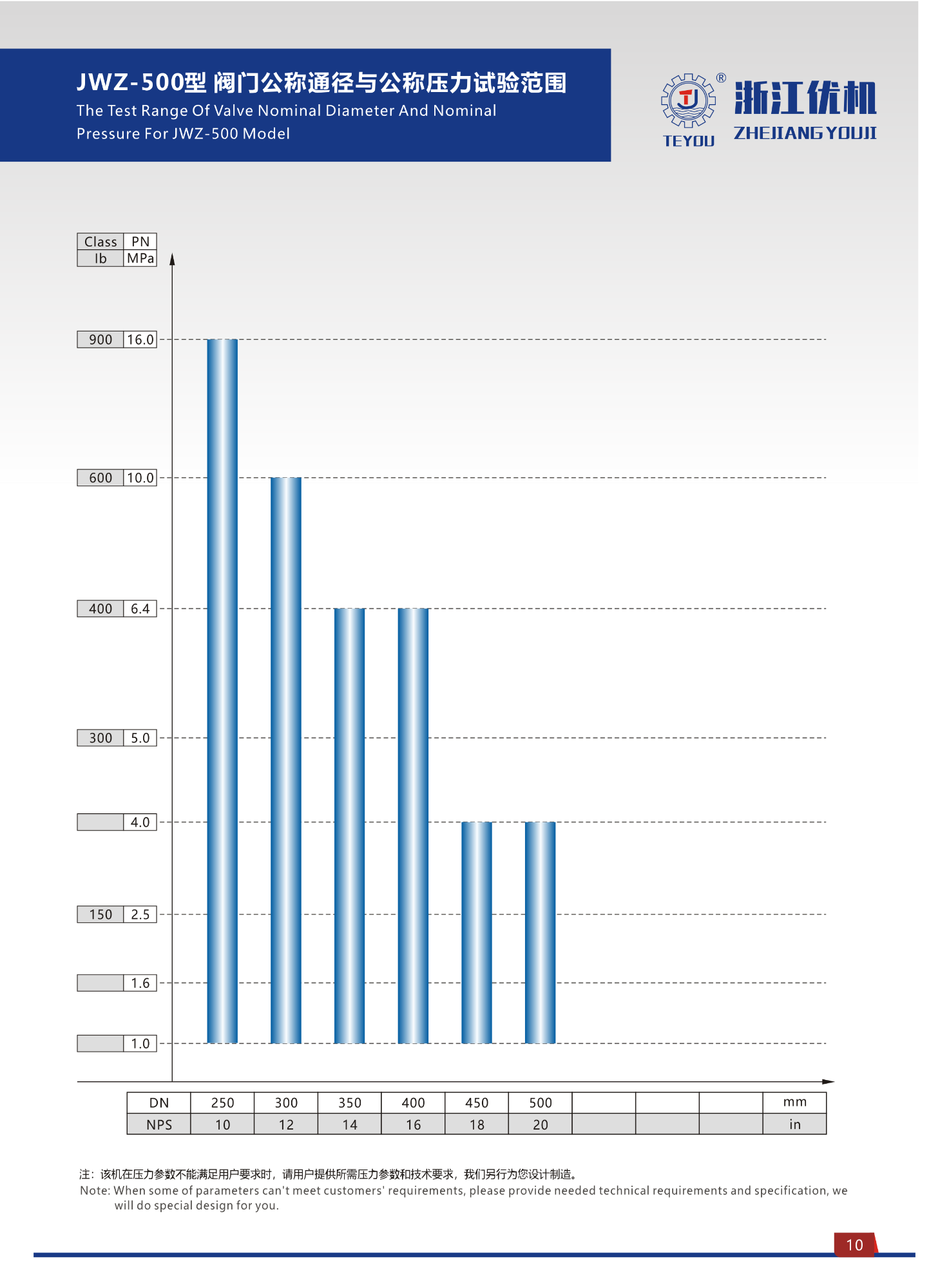

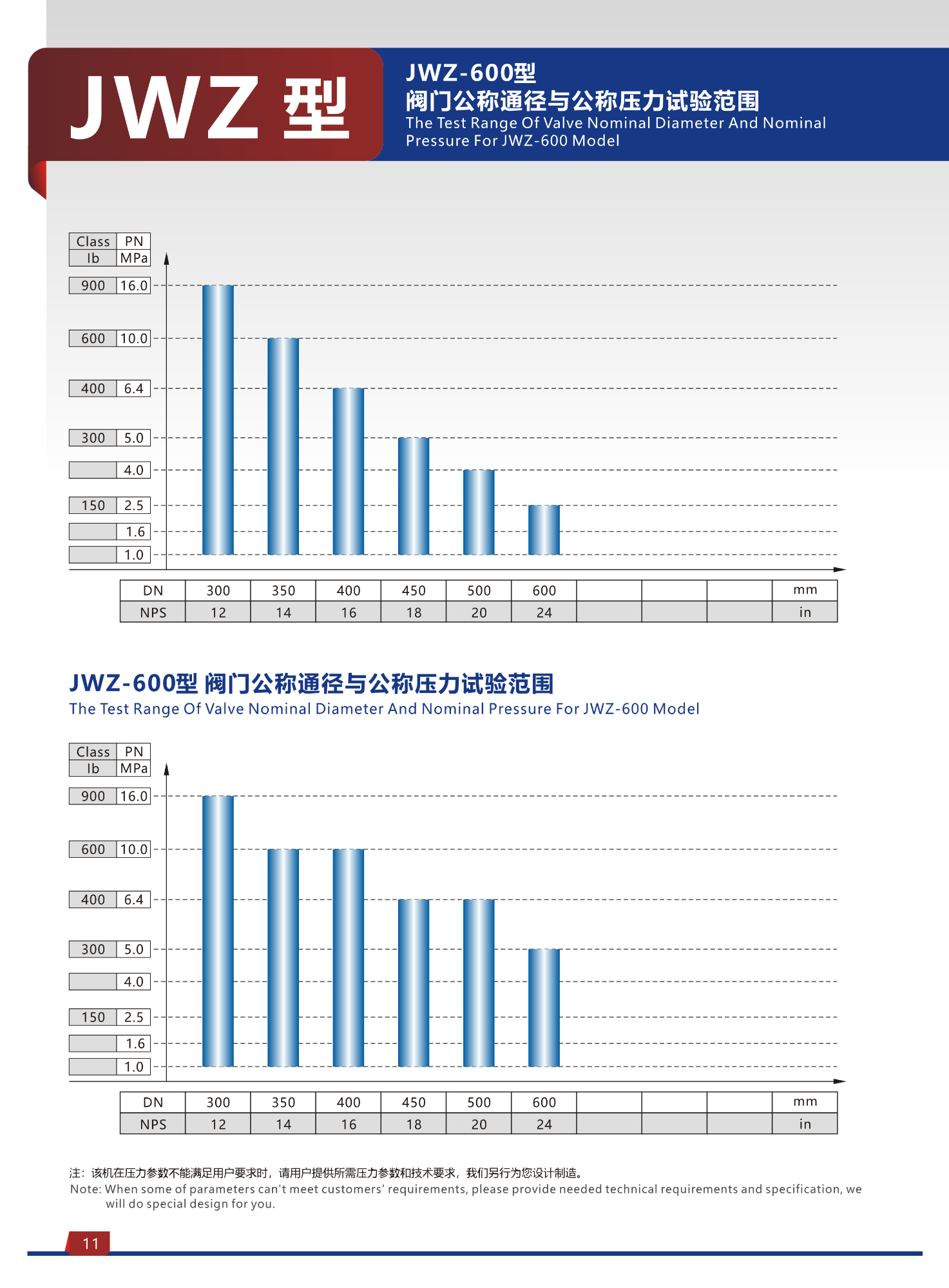

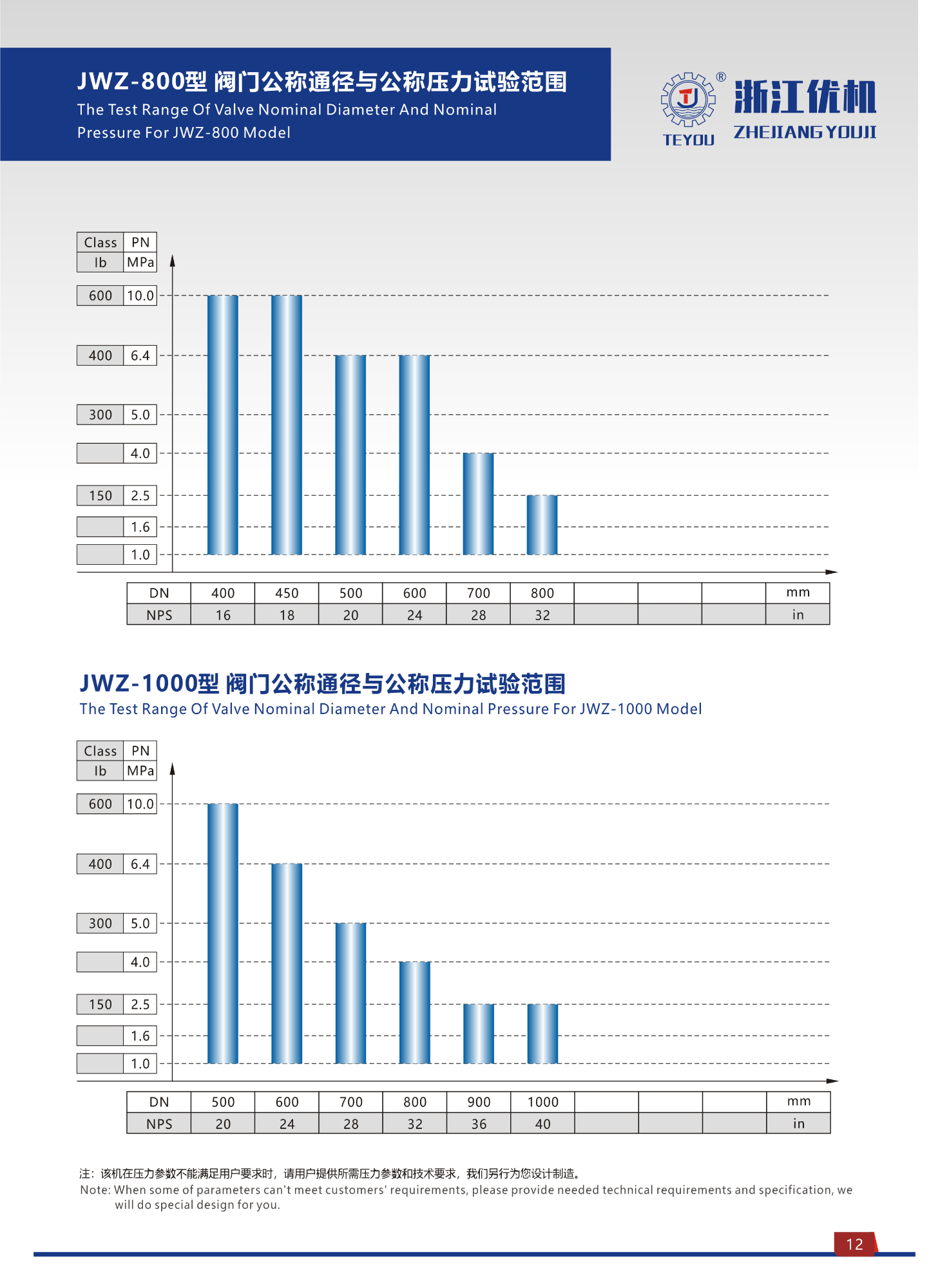

| Type specification | JWZ-100 | JWZ-200 | JWZ-300 | JWZ-400 | JWZ-500 | JWZ-600 | JWZ-800 | JWZ-1000 |

|---|---|---|---|---|---|---|---|---|

| Nominal diameter (DN) | 15-100 | 50-200 | 80-300 | 150-400 | 250-500 | 300-600 | 400-800 | 500-1000 |

| Nominal pressure (PN/MPa) | 1.6-32 | 1.6-32 | 1.6-32 | 1.6-32 | 1.0-16 | 1.0-16 | 1.0-10.0 | 1.0-10.0 |

| Max. distance (mm) | ≤700 | ≤850 | ≤1100 | ≤1200 | ≤1400 | ≤1500 | ≤1550 | ≤2350 |

| Min. distance (mm) | ≥200 | ≥250 | ≥280 | ≥350 | ≥450 | ≥450 | ≥550 | ≥550 |

| Axial travel (mm) | ≤60 | ≤70 | ≤85 | ≤105 | ≤105 | ≤105 | ≤105 | ≤105 |

| Radial travel (mm) | ≤120 | ≤160 | ≤200 | ≤240 | ≤250 | ≤230 | ≤250 | ≤360 |

| Pressure adjustment range (MPa) | 0-6.3 | |||||||

| Flow (L/min) | 16 | 16 | 16 | 25 | 25 | 40 | 50 | 50 |

| High pressure (MPa) | 3.0-31.5 | |||||||

| Pressure for oil pump (MPa) | 0-5.0 | |||||||

| Voltage (V) | 380 | |||||||

| Frequency (Hz) | 50 | |||||||

| Power (KW) | 1.5 | 2.2 | 2.2 | 3 | 3 | 5.5 | 5.5 | 5.5 |

| Pole | 6 | |||||||

| L (mm) | 2950 | 3200 | 3400 | 3800 | 4300 | 4350 | 4600 | 5400 |

| B (mm) | 1530 | 1550 | 1700 | 1900 | 1950 | 2050 | 2500 | 2350 |

| H (mm) | 1700 | 1750 | 1750 | 1750 | 1850 | 1850 | 1850 | 2300 |

| Weight (kg) | 2100 | 2500 | 3400 | 4800 | 5100 | 6200 | 8300 | 13000 |

Application Areas

- Valve Manufacturing Plants

- Oil & Gas Industry (Upstream, Midstream, Downstream)

- Petrochemical and Chemical Processing

- Nuclear and Conventional Power Generation

- Valve Repair and Maintenance Services

Why Choose YOUJI’s JWZ Valve Test Bench?

Accuracy & Reliability

Our patented clamping design and adherence to API and GB standards mean you can trust the results. We provide objective, repeatable data for every test.

Operational Efficiency

The automated, integrated system simplifies the testing process, from valve clamping to pressure control and data logging, increasing throughput and reducing operational costs.

Versatility

One machine handles a wide range of valve types, sizes, and pressure classes. The ability to test with water, air, or oil provides maximum flexibility for different applications, including as a hydrostatic valve testing machine.

Durability & Safety

Built with a robust carbon steel frame and equipped with multiple safety mechanisms, the JWZ test stand is designed for long-term, safe operation in demanding industrial environments.

Support & Service

- Professional installation and on-site commissioning.

- Detailed operational and maintenance training for your team.

- Responsive after-sales service and technical support.

- Ball valve testing equipment,Gate valve testing machine,Gate valve test bench。Readily available spare parts to ensure maximum uptime.