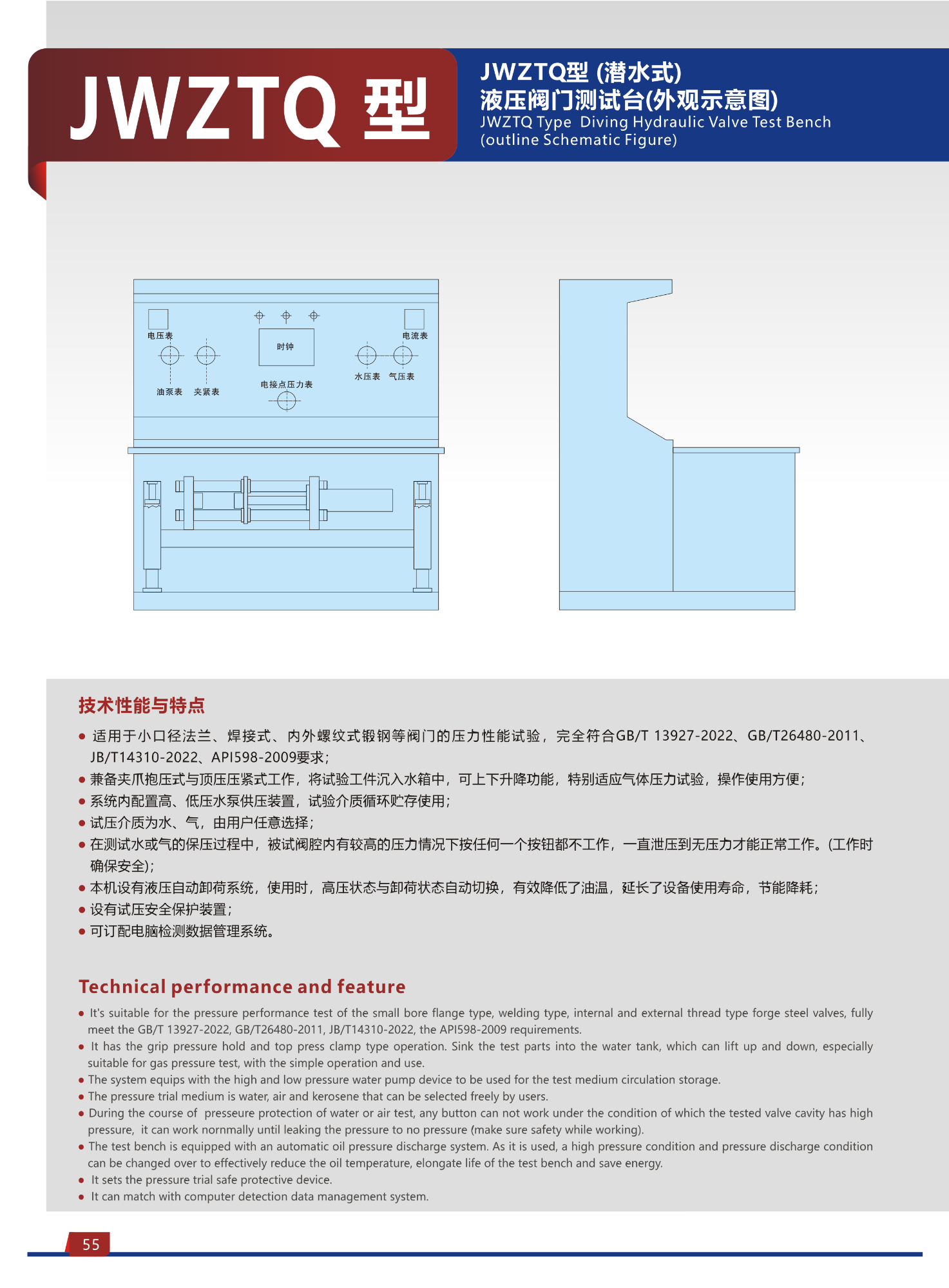

The YOUJI JWZTQ Type Diving Hydraulic Valve Test Bench is a specialized system engineered for high-precision pressure testing, particularly for pneumatic (gas) applications. Its core feature is a submersible design where the test piece is lowered into an integrated water tank, allowing operators to visually and accurately detect leaks from valve seals under gas pressure. This makes it the definitive solution for testing small-bore forged steel valves, including flanged, welded, and threaded types.

By providing a safe, controlled, and visually verifiable testing environment, the JWZTQ bench ensures full compliance with stringent industry standards such as API 598-2009, GB/T 13927-2022, and JB/T14310-2022. It is an indispensable tool for manufacturers and service centers that require irrefutable proof of a valve’s sealing integrity.

Key Features

- Submersible Design for Gas Leak Detection: The integrated water tank and lift mechanism allow the clamped valve to be fully submerged. This provides a clear, bubble-tight visual confirmation during gas seal tests, which is the most reliable method for detecting minute leaks.

- Versatile Clamping System: Equipped with both jaw-clamping and top-press mechanisms to securely hold a variety of small-bore valves without inducing stress that could compromise test results.

- Advanced Safety Interlocks: To ensure operator safety, the system automatically disables all function buttons when high pressure is detected in the valve. Operations can only resume once the pressure is fully and safely released.

- Energy-Efficient Hydraulics: Features an automatic hydraulic unloading system that intelligently switches between high-pressure and unloaded states. This reduces oil temperature, extends the equipment’s service life, and lowers energy consumption.

- Dual-Medium Capability: The system is equipped with high and low-pressure water pumps and supports both water (hydrostatic) and gas (pneumatic) as test media, selectable by the user. The test medium is stored and recycled within the system.

- Optional Data Management: Can be configured with a computer-based data acquisition system for digital recording, analysis, and generation of test reports and certificates.

Technical Specifications

| Specification | Details |

|---|---|

| Model | JWZTQ Type Diving Hydraulic Valve Test Bench |

| Primary Application | Submerged pneumatic (gas) and hydrostatic testing of small-bore valves |

| Applicable Valve Types | Forged steel valves (gate, globe, ball, check, etc.) |

| Connection Types | Flanged, Welded, Internal & External Threaded |

| Clamping Mechanism | Hydraulic Jaw-Clamping & Top-Press |

| Special Feature | Integrated water tank with vertical lift for submerging test piece |

| Test Media | Water, Gas (user-selectable) |

| Control System | Hydraulic Drive, Push-Button Control |

| Compliance Standards | GB/T 13927-2022, GB/T26480-2011, JB/T14310-2022, API 598-2009 |

| Safety Features | Pressure interlock, Automatic hydraulic unloading, General safety protection |

Application Areas

- Valve Manufacturing (especially forged steel and small-bore valves)

- Oil & Gas Equipment Suppliers

- Chemical and Petrochemical Industries

- Instrumentation and Control Valve Workshops

- Third-Party Valve Testing and Certification Facilities

Why Choose the YOUJI JWZTQ Test Bench?

- Unmatched Gas Testing Accuracy: The submersible design eliminates guesswork. Visual bubble detection is the industry-accepted standard for confirming a true bubble-tight seal.

- Engineered for Safety: With multiple integrated safety systems, including pressure interlocks and automatic unloading, the JWZTQ is designed to protect both the operator and the equipment.

- Full Standards Compliance: Guarantee that your valves are tested according to the latest and most stringent industry standards, including API 598.

- Efficient and Reliable: The dual-purpose design for both gas and water, combined with an energy-saving hydraulic system, provides a robust and cost-effective testing solution.

Support & Service

YOUJI provides complete support to ensure you get the most from your JWZTQ test bench. Our services include professional installation guidance, comprehensive operator training with a focus on safety, and responsive after-sales support for maintenance and technical inquiries.