Description

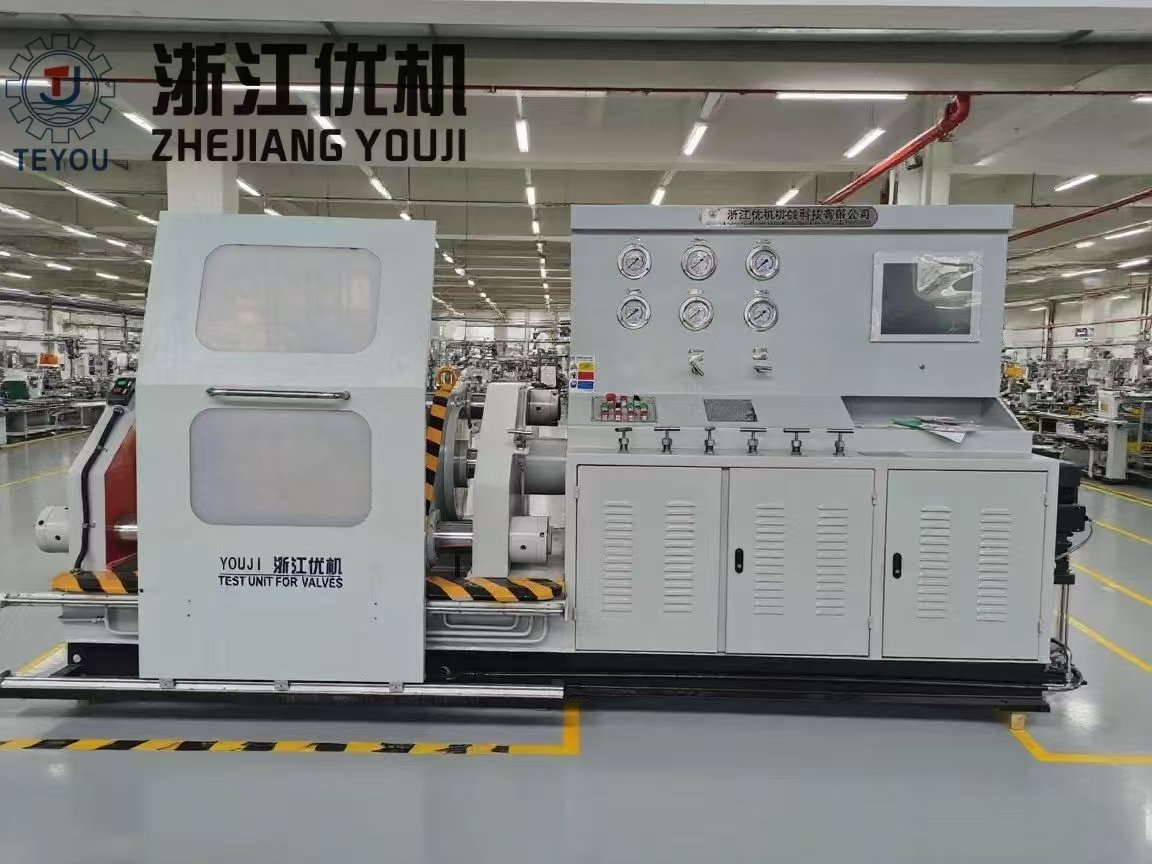

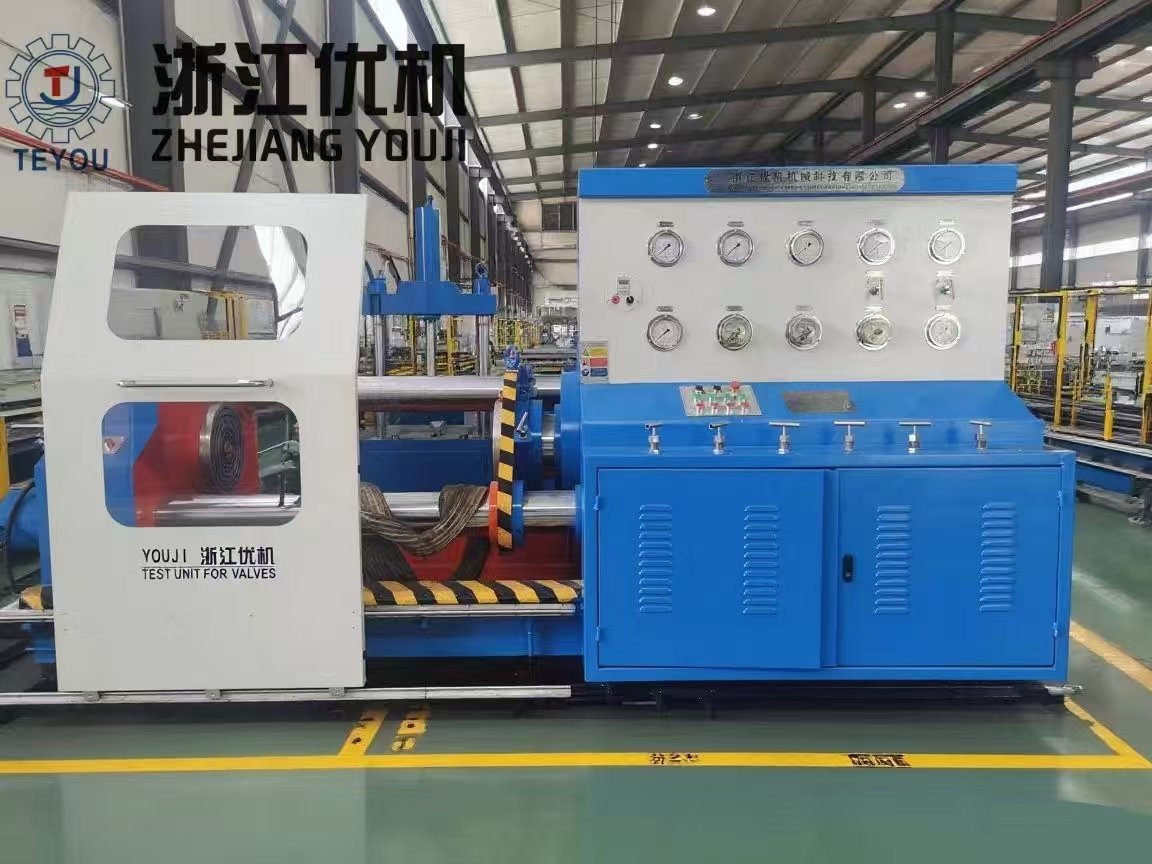

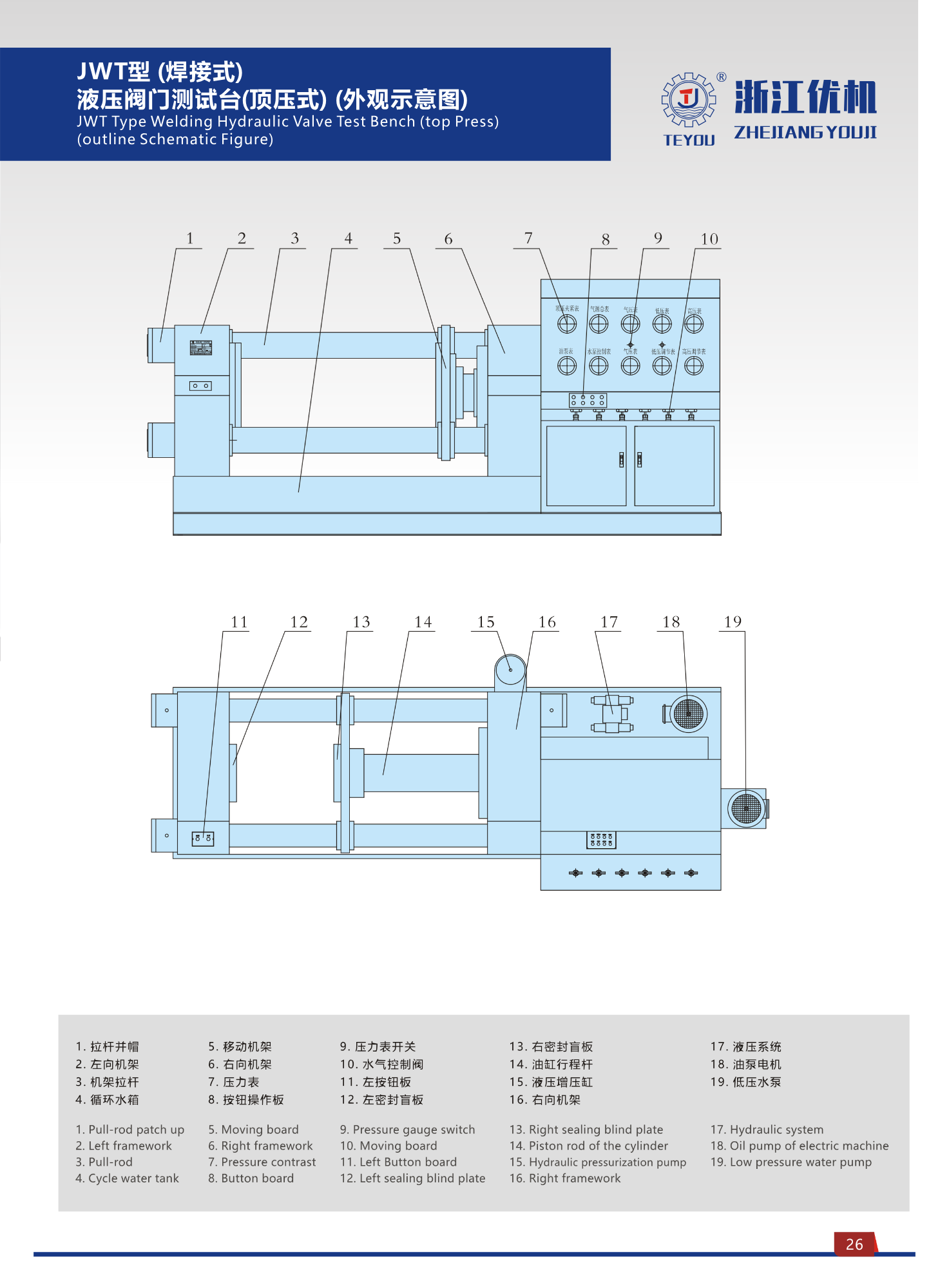

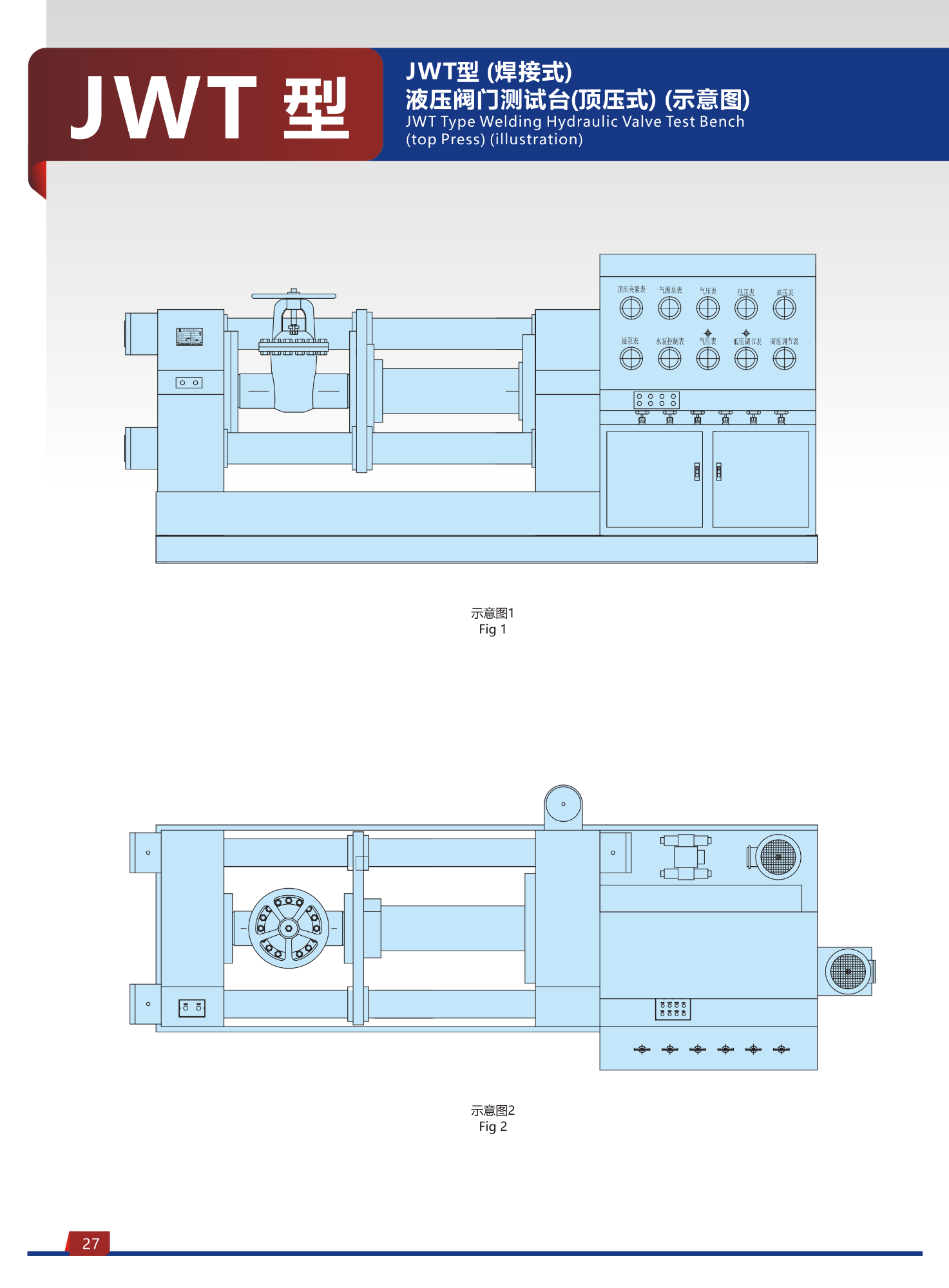

The JWT Model is a new-generation, top-clamping hydraulic valve test bench, protected by national patent (ZL2016 1 0240324.1). It is specifically engineered to address the complex testing requirements for both non-flanged (welded) and standard flanged valves within a single, efficient system. Designed for valve manufacturers and end-users in critical sectors, the JWT Model provides accurate and reliable strength and sealing performance tests, ensuring your valves meet the most stringent industry standards. Two variants are available: a standard push-button control system and an advanced PLC computer-controlled system for automated testing and data management.

Key Features

- Patented Top-Clamping Design: Our innovative top-pressure clamping mechanism (Patent No. ZL2016 1 0240324.1) provides a stable and secure grip, especially for testing welded-end valves (e.g., J61, J63, Z61) that lack flanges.

- Versatile Valve Compatibility: Accommodates a wide array of valve types including gate, globe, ball, and check valves with welded, flanged, or clamp connections.

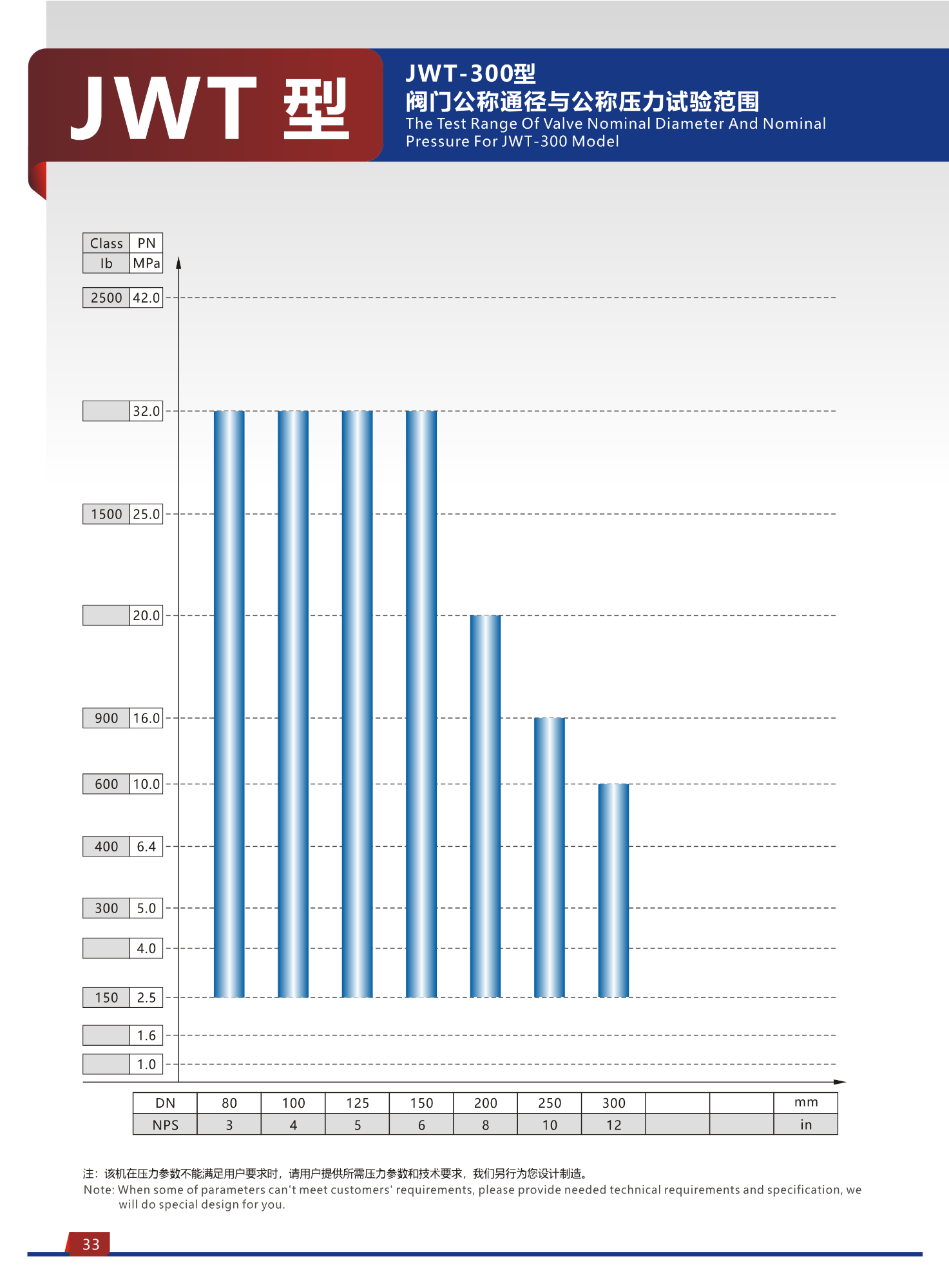

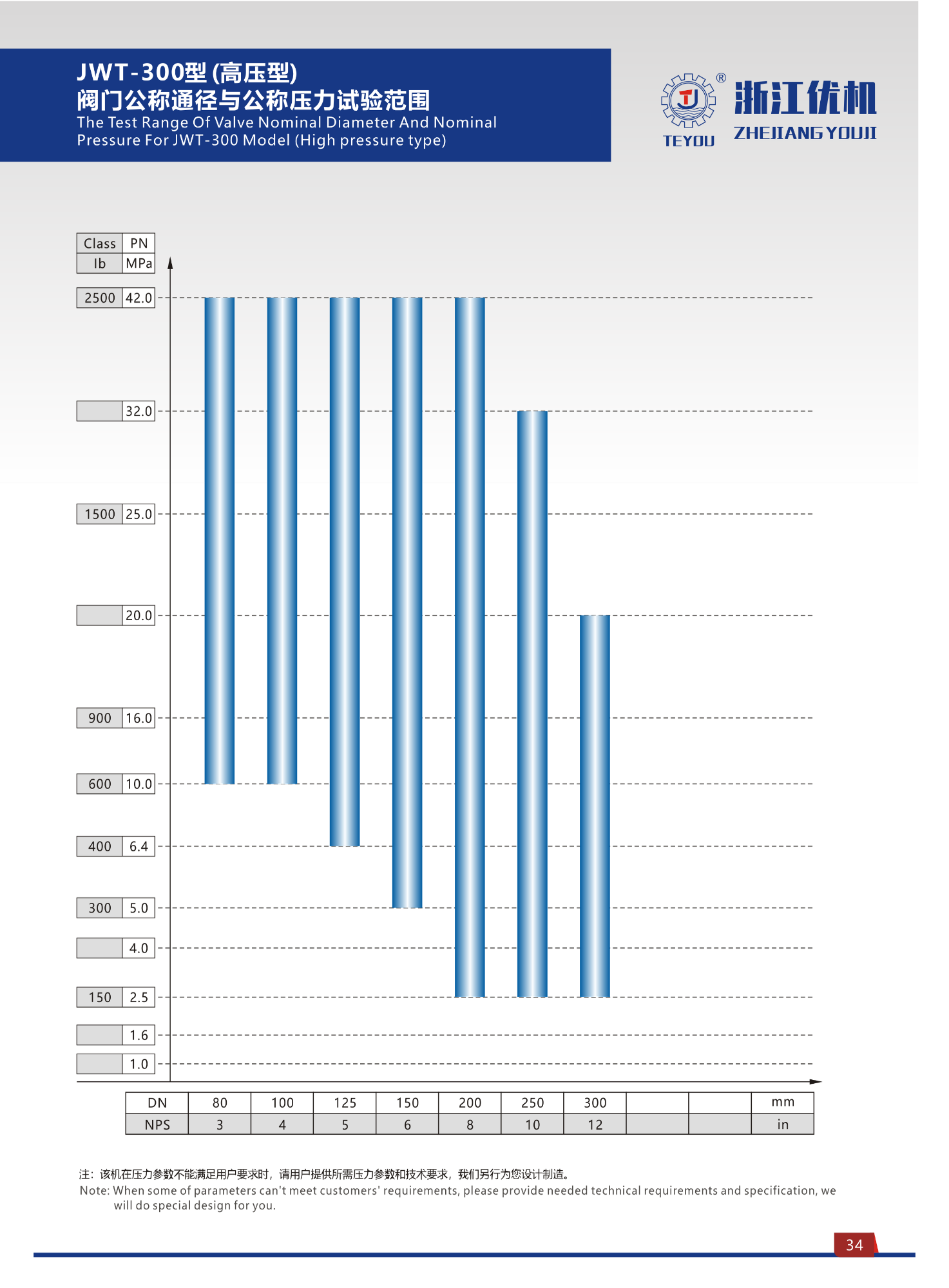

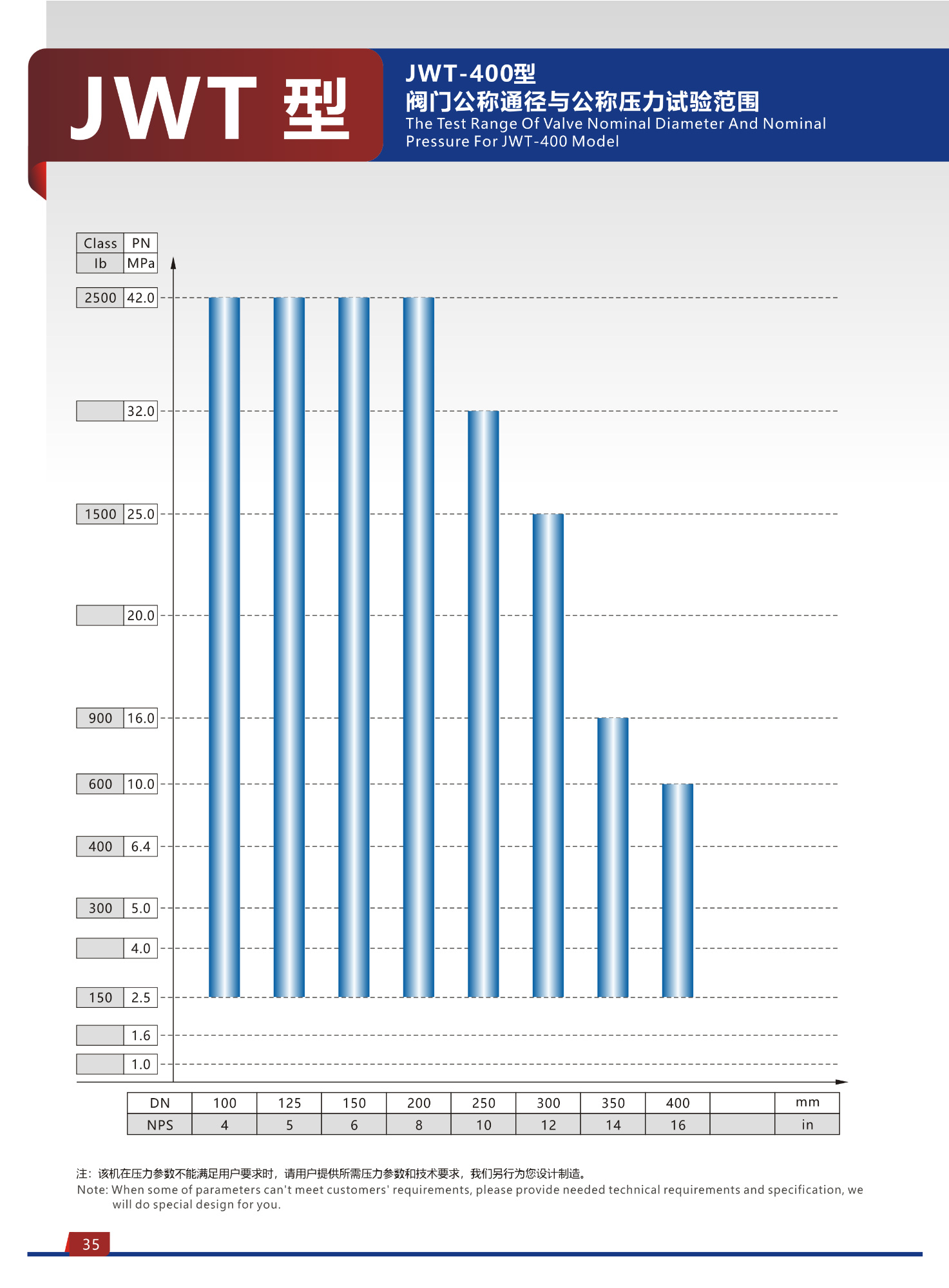

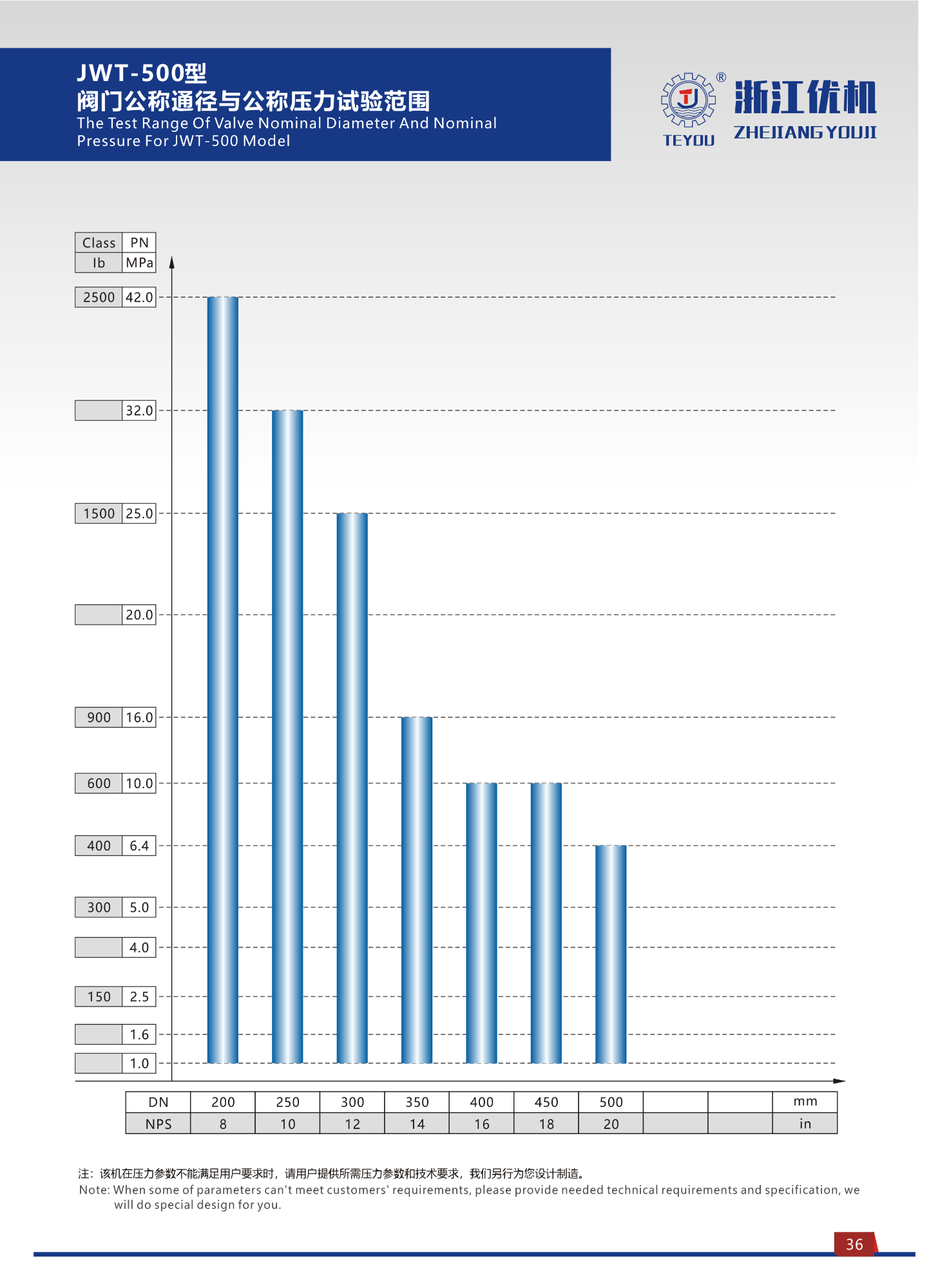

- Wide Testing Range: Capable of testing valves with nominal diameters from DN15 to DN1200 (NPS 1″ to 28″), with custom solutions available up to DN1800.

- Advanced Safety Interlocks: To ensure operator safety, the system prevents operation of any function buttons when the valve cavity is under high pressure. All pressure must be fully released before the system accepts new commands.

- Energy-Efficient Hydraulics: Features an automatic hydraulic unloading system that reduces oil temperature, significantly extends equipment lifespan, and lowers energy consumption.

- Optional Computerized Control: Upgrade to the computer-controlled model for automated test cycles, real-time data acquisition, pressure curve analysis, and report generation.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | JWT Model (Push-Button or Computer-Controlled) |

| Nominal Diameter Range | DN15 ~ DN1200 (NPS 1″ ~ 28″) |

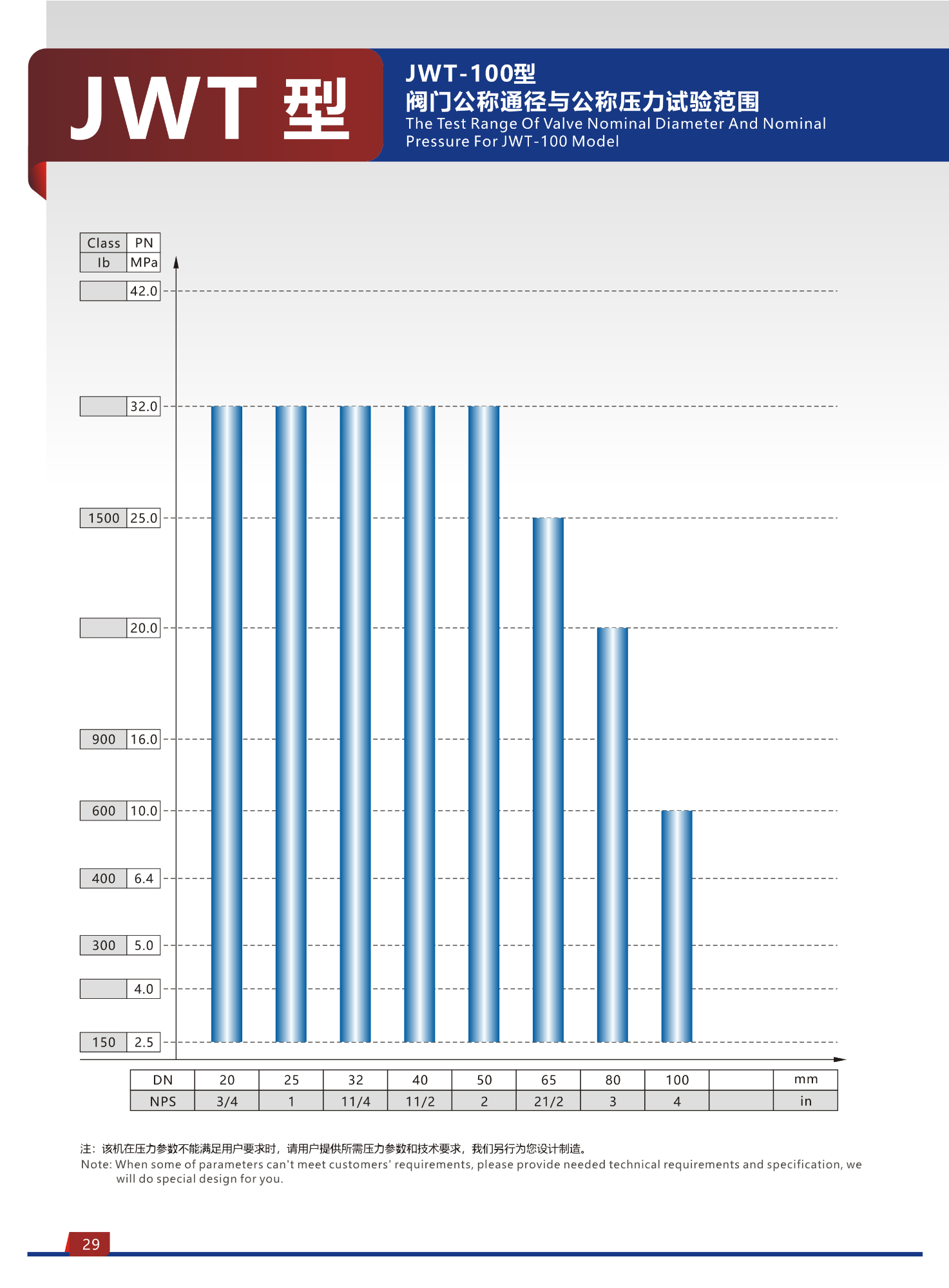

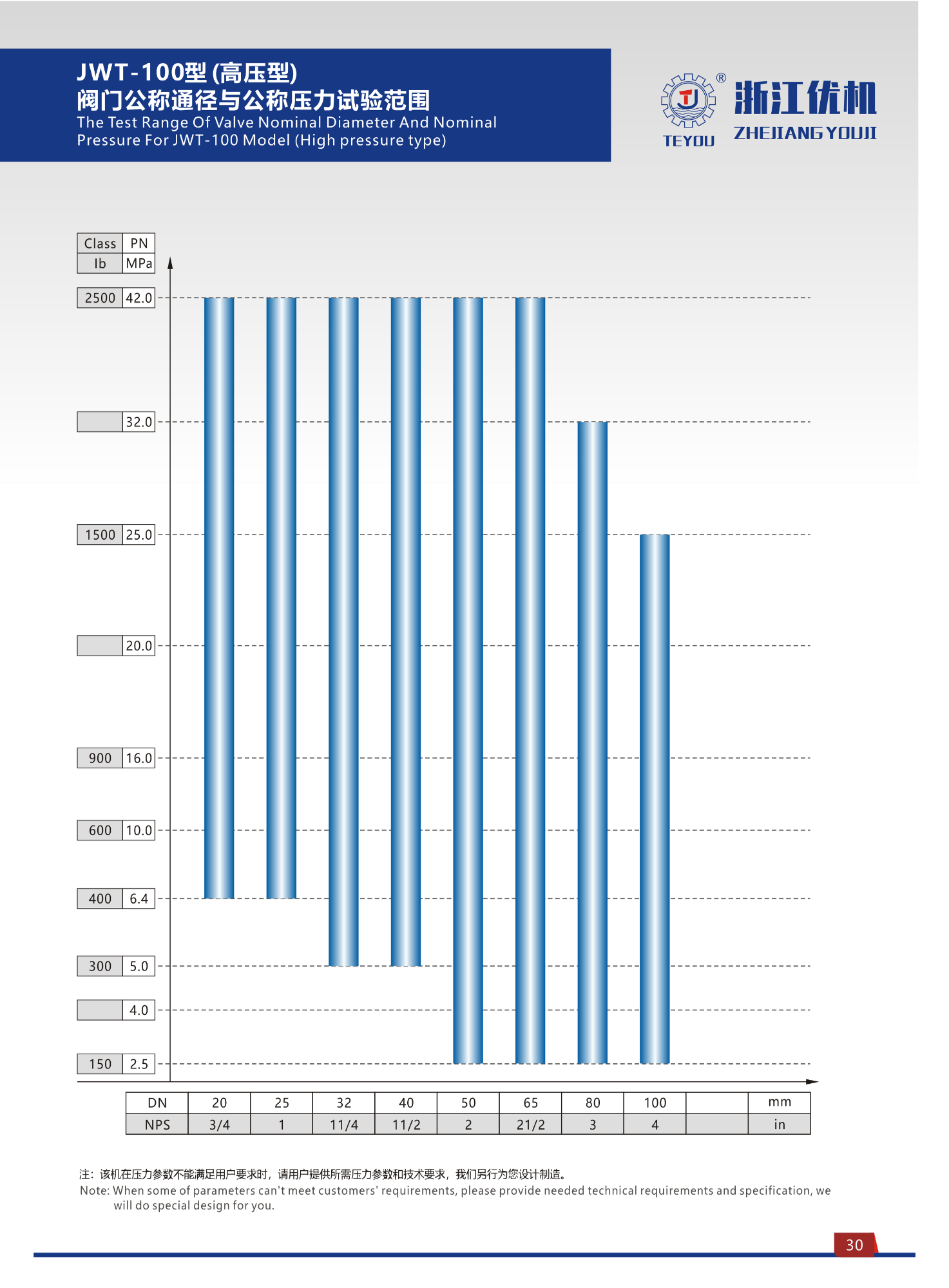

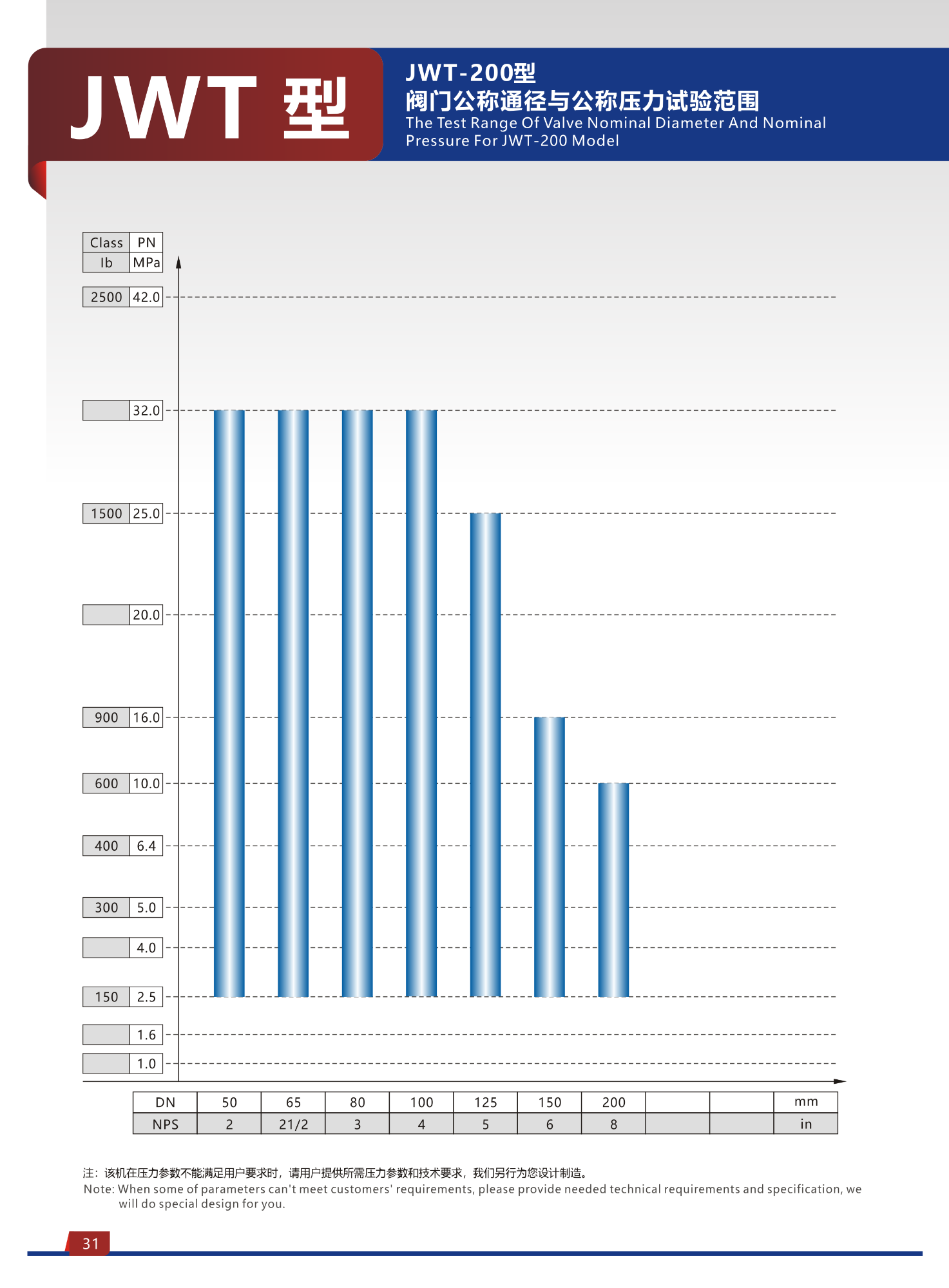

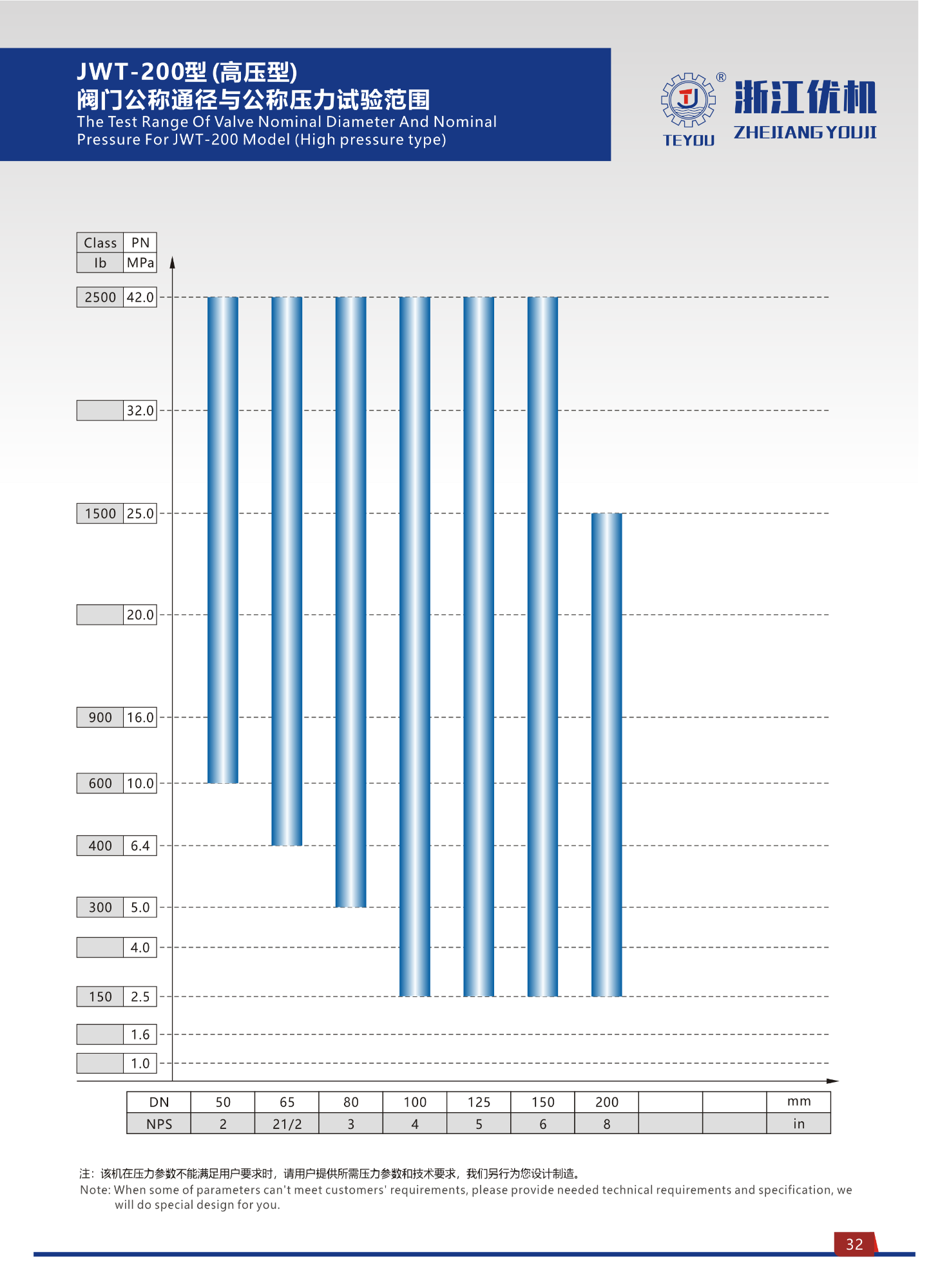

| Pressure Range | PN1.6 ~ 48 MPa (Class150 ~ 2500 lb) |

| Maximum Seal Test Pressure | 32.0 MPa |

| Maximum Strength Test Pressure | 48.0 MPa |

| Applicable Valve Types | Gate Valves, Ball Valves, Globe Valves, Check Valves |

| Connection Types | Welded, Flanged, Clamp |

| Test Media | Water (with rust inhibitor), Oil, or Gas (user-specified) |

| Control System | Hydraulic Drive with Push-Button Control / PLC Computer Control |

| Frame Material | High-Strength Q325A Steel |

| Standards Compliance | GB/T 13927-2022, API 598-2009, GB/T26480-2011, JB/T14310-2022 |

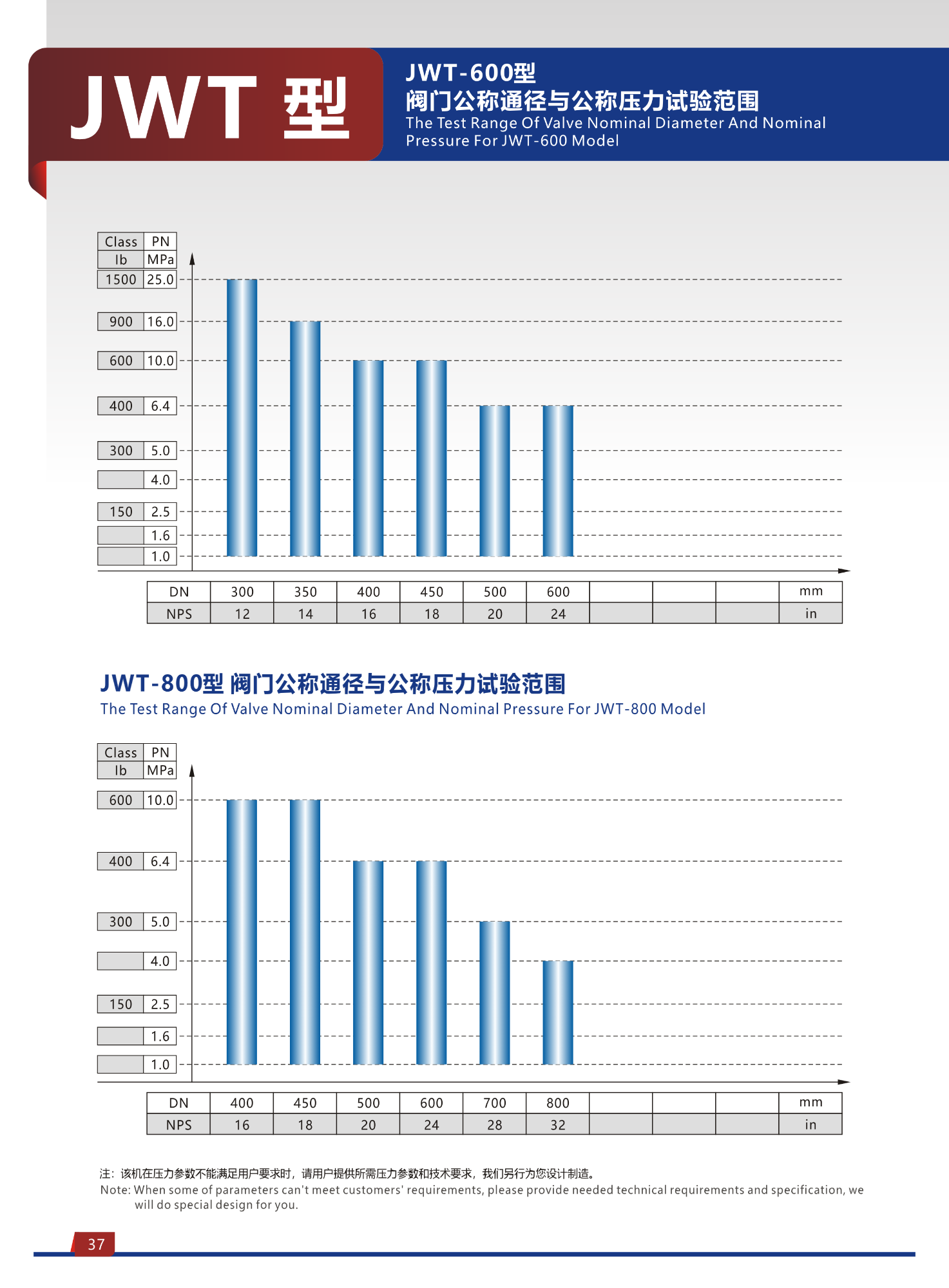

| Type specification | JWT-100 DN15-100 mm | JWT-200 DN50-200 mm | JWT-300 DN80-300 mm | JWT-400 DN100-400 mm | JWT-500 DN200-500 mm | JWT-600 DN300-600 mm | JWT-800 DN400-800 mm |

|---|---|---|---|---|---|---|---|

| Voltage (V) | 380 | ||||||

| Frequency (Hz) | 50 | ||||||

| Power (KW) | 2.2 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

| Grade | 6 | ||||||

| Highest work pressure of oil pump (MPa) | 6.3 | ||||||

| Highest work pressure of hydraulic cylinder (MPa) | 31.5 | ||||||

| Highest testing pressure of biggest diameter (MPa) | 32.0 | 32.0 | 25.0 | 10.0 | 6.4 | 6.4 | 4.0 |

| Effective biggest span (mm) | 750 | 1200 | 1350 | 1350 | 1350 | 1350 | 1550 |

| Effective smallest span (mm) | 120 | 220 | 250 | 300 | 350 | 400 | 500 |

| Highest work pressure of hydraulic pressure supplying setting (MPa) | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 | 25.0 | 20.0 |

| L (mm) | 2600 | 3100 | 3600 | 3650 | 3700 | 4150 | 4500 |

| B (mm) | 1100 | 1350 | 1500 | 1600 | 1700 | 1900 | 2300 |

| H (mm) | 1850 | ||||||

| Weight (kg) | 2800 | 4200 | 5700 | 6400 | 6800 | 7500 | 8300 |

Application Areas

- Valve Manufacturing Plants

- Oil & Gas (Upstream, Midstream, Downstream)

- Petrochemical & Chemical Processing

- Nuclear Power Facilities

- Power Generation

- Valve Maintenance and Repair Services

Competitive Advantages: Why Choose the JWT Model?

- Patented Technology: Our unique, patented design offers a proven solution for a common industry challenge—testing welded valves effectively and safely.

- Engineered for Accuracy & Safety: Beyond standard compliance, we integrate features like hydraulic auto-unloading and pressure interlocks, demonstrating our commitment to operator safety, equipment longevity, and precise results.

- Unmatched Versatility: A single machine that capably handles a vast range of sizes, pressure classes, and connection types, maximizing your ROI and floor space.

- Robust & Reliable Construction: Built with a high-strength steel frame and reliable hydraulic components, the JWT model is designed for continuous operation in demanding industrial environments.

- Certified Performance: Full compliance with key international and national standards like API 598 provides third-party validation of our testing methodology and gives you complete confidence in your results.

Support & Service

is committed to your success. We provide comprehensive support for every valve testing system we deliver:

- Professional Installation & Commissioning

- On-site Operator Training

- Lifetime Technical Support

- Readily Available Spare Parts

- Customization Services to Meet Specific Needs