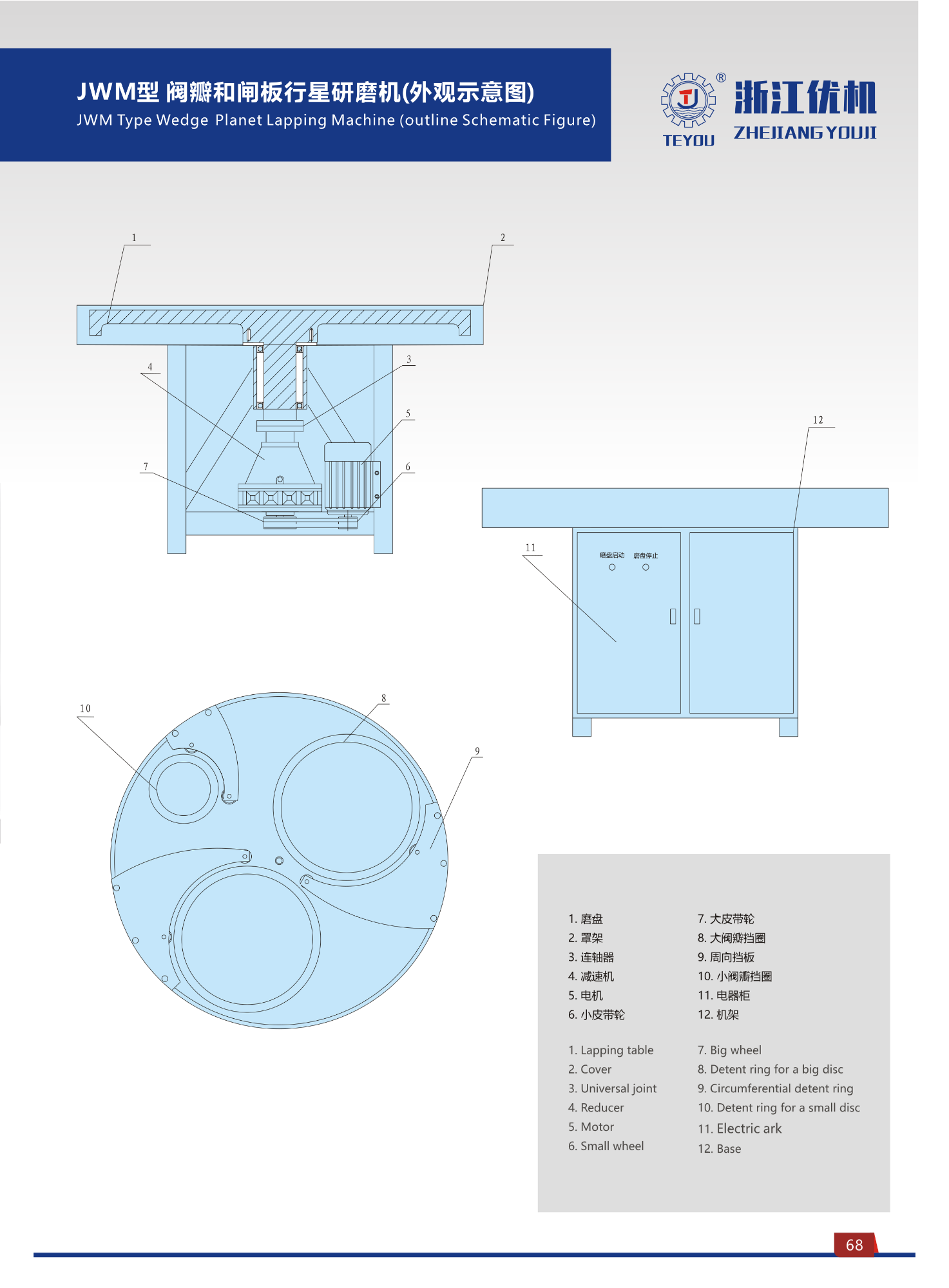

Achieving a flawless seal is the ultimate goal in valve performance. The JWM Model Planetary Lapping Machine is a state-of-the-art solution engineered to deliver exceptional surface finish and sealing conformity on valve discs, wedges, and seats. Leveraging a patented design with planetary motion, this machine provides a non-repetitive, uniform grinding pattern that is impossible to achieve with manual methods. The JWM Model is the ideal equipment for valve manufacturers and service workshops aiming to enhance product quality, increase production throughput, and reduce operational labor costs.

Key Features

- Advanced Planetary Motion: The core of the JWM Model is its unique grinding mechanism where workpieces both revolve around a central axis and rotate on their own. This dual motion ensures a random, cross-hatched lapping pattern, resulting in a perfectly flat, non-directional surface finish.

- Exceptional Surface Finish: The machine consistently produces a highly polished sealing surface with a roughness of $Ra \le 0.8 \mu m$, creating a mirror-like finish that significantly reduces the potential for leaks.

- High Sealing Conformity: The precision of the planetary action guarantees a sealing contact area (吻合度) of $\ge 80\%$, ensuring a tight and reliable seal under pressure.

- High-Efficiency Operation: Designed for ease of use and low labor intensity. A single operator can manage multiple JWM machines simultaneously, drastically increasing production efficiency and reducing costs.

- Variable Frequency Control: The integrated variable frequency drive allows for precise control over the lapping speed, enabling operators to optimize the process for different workpiece materials and grinding compounds.

- Secure Workpiece Fixturing: The lapping plate is equipped with robust positioning rings to securely hold multiple valve discs or gate valve wedges, ensuring stability and consistency throughout the grinding cycle.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | JWM Planetary Valve Lapping Machine |

| Application | High-precision lapping of valve discs, valve seats, gate valve wedges |

| Applicable Diameter | DN50 – DN900 |

| Lapping Motion | Planetary (Simultaneous Revolution and Rotation) |

| Achievable Surface Roughness | $Ra \le 0.8 \mu m$ |

| Achievable Sealing Conformity | $\ge 80\%$ |

| Control System | Variable Frequency Drive (VFD) for Speed Control |

| Drive System | Cycloidal Pin-wheel Reducer |

| Intellectual Property | National Patent Held by |

| 型号 Type | 规格 Specification | 电机型号 Motor Type | 功率 Power | 电压 Voltage | 频率 Frequency | 转速 RPM |

|---|---|---|---|---|---|---|

| JWM-1000型 | DN50–250 | Y112M-4 | 2.2 (4极) | 380V | 50Hz | 1440 r/min |

| JWM-1200型 | DN50–300 | Y112M-4 | 3.0 (4极) | 380V | 50Hz | 1440 r/min |

| JWM-1400型 | DN100–400 | Y112M-4 | 3.0 (4极) | 380V | 50Hz | 1440 r/min |

| JWM-1600型 | DN100–500 | Y112M-4 | 4 kW (4极) | 380V | 50Hz | 1440 r/min |

| JWM-1800型 | DN200–600 | Y112M-4 | 5.5 (4极) | 380V | 50Hz | 1440 r/min |

| JWM-2000型 | DN250–700 | Y112M-4 | 5.5 (4极) | 380V | 50Hz | 1440 r/min |

| 备注:减速机采用摆线针轮减速机,型号:XW6-43-SZ Note: Choose cycloidal pinwheel reducer, type: XW6-43-SZ | ||||||

Application Areas

- Valve Manufacturing Facilities

- Valve Repair, Overhaul, and Service Workshops

- Oil & Gas Component Maintenance

- Power Plant and Nuclear Facility Maintenance

- Petrochemical and Chemical Processing Plants

- Any industry requiring high-precision flat lapping for critical sealing components.

Competitive Advantages: Why Choose the JWM Model?

- Superior Sealing Performance: The verified surface roughness and high conformity directly translate to superior valve performance, lower leak rates, and increased operational safety for your customers.

- Patented Technology: Unlike standard lapping machines, the JWM model is a proprietary, patented design, giving you access to a unique and more effective finishing technology.

- Significant Labor Cost Reduction: The ability for one operator to oversee several machines offers a clear and rapid return on investment by optimizing your workforce and increasing output.

- Unmatched Consistency: The machine eliminates the variability and inconsistencies of manual lapping, delivering repeatable, high-quality results for every workpiece, every time.

Support & Service

is dedicated to maximizing the value of your investment. We offer a full suite of services for our JWM Lapping Machines:

- Professional Installation and On-site Commissioning

- Comprehensive Operator Training

- Expert Consultation on Lapping Processes and Compounds

- Dedicated After-Sales Support and Spare Parts Availability