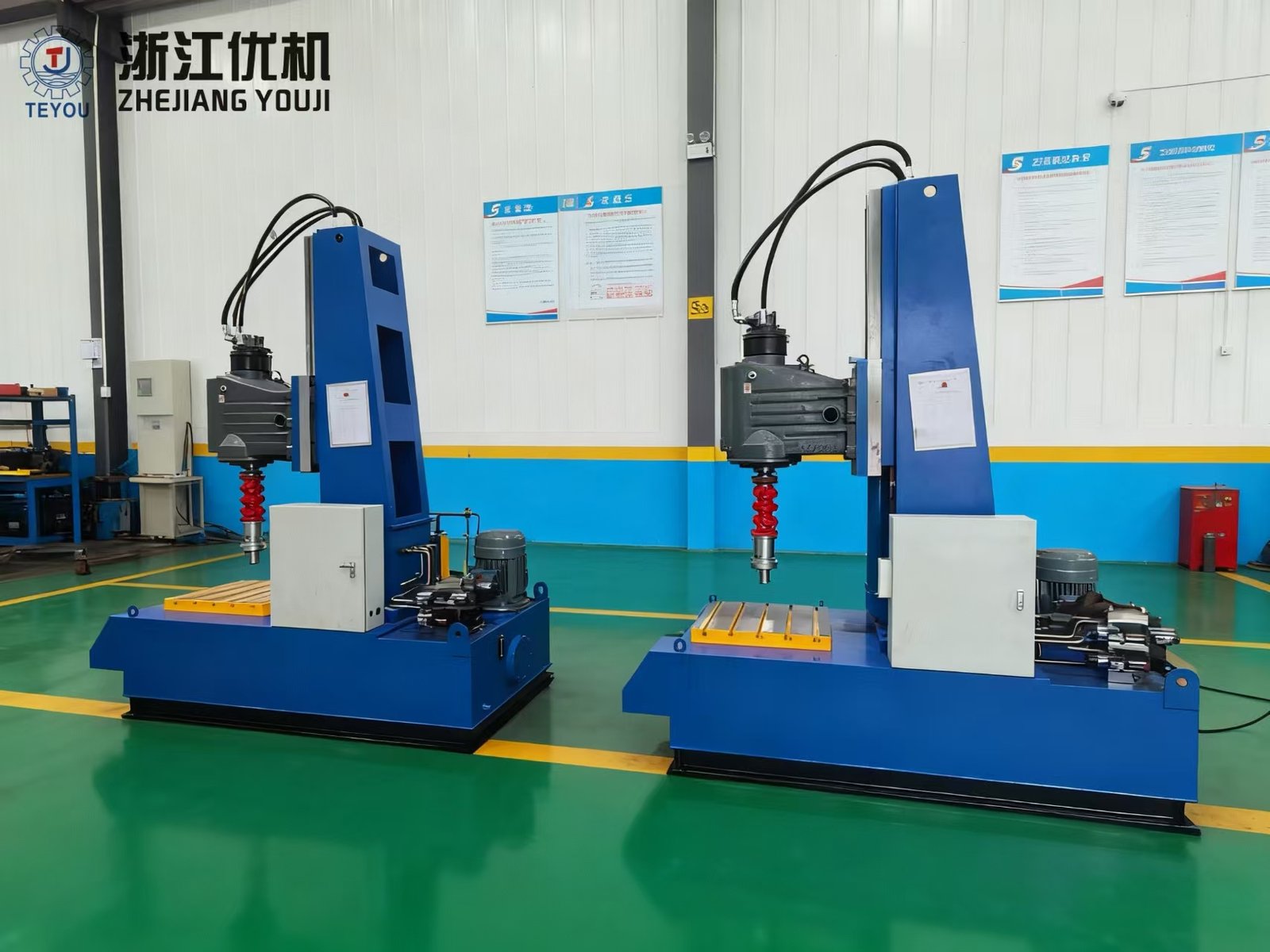

The JLX Type Plug Valve Grinding Machine (Dual Station) is engineered for hard-seal plug valve seating surfaces. It combines $360^\circ$ forward and reverse rotation with an automatic vertical lift five times per rotation, preventing galling between the valve body seat and the plug sealing surface. The system delivers high machining accuracy, excellent surface finish, and consistent batch quality for manufacturers and valve service shops.

Key Features

- Dual-station configuration for higher throughput; single-station available on request.

- $360^\circ$ forward & reverse rotation plus automatic vertical lift (5 times per cycle) to avoid surface damage.

- Hydraulic motor with adjustable speed (1–600 $r/min$) based on valve size and material.

- Universal joint and telescopic rod linkage for precise alignment and controlled sealing pressure.

- Supports rough and fine grinding with flexible abrasives; floating lapping optional.

- Hydraulic cylinder lift for stable, precise up/down motion.

Technical Specifications

| Specification | Unit | JLX-200 |

|---|---|---|

| Applicable Valve Size | mm | DN50–DN200 |

| Power Supply Voltage | V | 380V / 50Hz |

| Oil Pump Motor Power | kW | 5.5 |

| Hydraulic Motor Rated Torque | $N \cdot m$ | 760 |

| Hydraulic Motor Speed | $r/min$ | 1–600 |

| Gearbox Transmission Ratio | i | 5.24 |

| Gearbox Rated Torque | $N \cdot m$ | 1000 |

| Output Shaft Reciprocating Stroke | mm | 9 (5 reciprocations per rotation) |

| Machine Dimensions ($L \times W \times H$) | cm | 220 × 155 × 240 |

| Net Weight | kg | 3300 |

Configurations & Structure

JLX series is available in single-station and dual-station models. The system consists of a column frame, guide rail with lifting mechanism, gearbox rotation module, and clamping mechanism. The rotation centers are orthogonal for stability. Column and gearbox base lifting is driven by a hydraulic cylinder and controlled via push-button for upward/downward motion.

- Drive & Control: Hydraulic motor controls rotation; hydraulic flow regulates speed.

- Alignment: Gearbox and spindle connected via universal joint and telescopic rod for vertical compensation and pressure control on the sealing surface.

- Process: Choose suitable abrasives per process requirements; combine rough and fine grinding, or float-lap valve body and plug as needed.

Application Areas

- Hard-seat plug valve manufacturing and repair

- Maintenance for gate, ball, and globe valves

- Valve service workshops for Oil & Gas, Petrochemical, and Power

Competitive Advantages

- Prevents galling and extends component life through controlled lift and bidirectional rotation.

- High precision and repeatability for batch production.

- Flexible speed control matched to valve size and material.

- Configurable stations to suit capacity and footprint.

Support & Service

- On-site installation and operator training

- Process optimization and abrasive selection guidance

- Spare parts and after-sales technical support