With the rapid development of the machinery industry, grinding technology has been widely applied to general-purpose machine tools and other equipment. Building on years of hydraulic manufacturing experience and continuous innovation, we have developed the JLX-series plug valve hard-seat lapping machines, which reach advanced performance levels internationally.

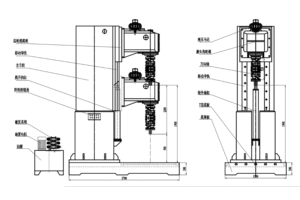

Grounded in lapping theory, the machine uses a gearbox driven by a hydraulic motor for variable speed, forward and reverse rotation, and controlled reciprocating “pecking” motion. The grinding spindle forms its motion trajectory through a universal joint and telescopic rod. An oil cylinder raises and lowers the gearbox-mounted grinding head. The valve body and plug move vertically via the universal joint, while the telescopic rod adjusts contact pressure on the sealing faces.

The result is easy operation, comprehensive functionality, compact structure, and high grinding precision. The machine can lap sealing faces of hard-seat plug valves across a wide size range.

The system integrates electromechanical, hydraulics, gearbox transmission, and a recirculating lapping-lubricant reservoir into one unit. It offers stable performance and a high degree of automation. It is widely used for lapping sealing faces of plug valves with nominal diameters DN300–600 mm, achieving smooth, flat finishes and excellent accuracy with approximately 90% fit.

In practice, the machine not only meets standard requirements for various valve lapping tasks, but also significantly improves efficiency and reduces labor intensity, earning strong feedback from valve manufacturing and petrochemical maintenance sectors.

Lapping System Operation Steps

- Start the hydraulic system. Manually clamp the valve body on the T-slot worktable and connect the lapping plug to the machine.

- Evenly apply lapping abrasive or compound to the valve body sealing face or the lapping plug.

- Use the lifting cylinder to lower the lapping plug and stop 5–10 mm above the sealing face.

- Start the hydraulic motor and reciprocating cylinder so the lapping plug performs up-down reciprocation with rotational reciprocation.

- Lower the lapping plug until, at the low point of its reciprocation, it just contacts the valve body sealing face. Lapping begins.

Technical Specifications — JLX-600

| <strong>Item</strong> | <strong>Unit</strong> | <strong>JLX-600</strong> |

|---|---|---|

| Applicable valve size | mm (in) | DN300–DN600 (12″–24″) |

| Opening height (vertical stroke window) | mm | 800–1900 |

| Power supply | V / Hz | 380 V / 50 Hz |

| Hydraulic pump motor power | kW | 7.5 |

| Hydraulic motor rated torque | N·m | 949 |

| Hydraulic motor speed | r/min | 8–630 |

| Gearbox ratio | i | 8.1 |

| Gearbox rated torque | N·m | TN2 = 8000 |

| Gearbox output reciprocation distance | mm | 8 (approx. 4.2 reciprocations per revolution) |

| Overall dimensions (L × W × H) | cm | 270 × 150 × 370 |

| Net weight | kg | 6500 |

Additional configuration notes:

- JLX-600: single-station. Lapping range: DN300–DN600.

- Gearbox up-down reciprocation: approx. 8 to 4.2 cycles.

- Lift cylinder up-down motion. Lifting cylinder thrust: 0–10 tons. Stroke: 0–1100 mm.

- Control hydraulic motor for oscillating rotation within a settable sector angle, adjustable from 90° to 360°.

- Universal coupling: nominal torque 20,000 N·m. Fatigue torque 10,000 N·m. Overall length 360. Double-flange connection.

Hydraulic System Features

Hydraulic unloading (new feature):

The system includes an automatic unloading circuit. When the machine is in standby, the hydraulic system automatically unloads. When any hydraulic action is initiated, pressure automatically returns to the normal setpoint.

This effectively controls oil temperature rise during continuous operation, significantly reducing oil temperature and power consumption, extending the service life of the pump, motor, and hydraulic components, and prolonging the life of sealing elements in hydraulic cylinders (imported polyurethane). It saves energy during testing and operation.

Hydraulic System Components and Process

- Pressure gauges: Anti-vibration gauges by Hangzhou Huake and Leierda.

- Solenoid valves: Shanghai Huada brand, Rexroth-standard pattern.

- Seals: O-rings by Taiwan Voltop. Cylinder seals made of imported TPU from Bayer (Germany).

- Hydraulic manifold blocks: Process ports locked by high-pressure screws. Pickled and nickel-plated finish.

- Gearbox: Manufactured by Zhejiang Youji Machinery Technology Co., Ltd.

- Pump motor: WanNan Motor, a well-known Chinese brand.

- Electrical: Chint components. Push buttons by Hongbo Group (Schneider style).

- Hydraulic motor: Ningbo Tailerms Hydraulics Co., Ltd.

- Universal joint: Wuxi Saiwei Machinery Co., Ltd.

- Air-cooled hydraulic oil cooler: For oil tank heat dissipation.

Main Parts — Materials and Processes

- Piston rods: 40Cr, quenched and tempered to HRC28–32, hard-chrome plated.

- Cylinders: Cold-drawn seamless steel tube.

- Pistons: Wear-resistant gray cast iron, QT-450.

- Guideways: 42CrMo.

- Cabinet frame: Welded Q235A.

- T-slot worktable: Cast iron 355 grade.

- Main column: Welded Q235.

- Paint: Eco-friendly water-based system, off-white by default. Three-coat process: primer, anti-rust, top coat. Custom colors available to match site environment.

Documentation Provided

Packing list, certificate of conformity, and one set of manuals, including hydraulic schematics, pneumatic and water line schematics, operating instructions, and common troubleshooting.

Site Installation and Operating Conditions

- Ambient temperature: 1–40 ℃

- Relative humidity: ≤ 90% RH

- Environment: No high-concentration dust or corrosive gases. Do not use or store in flammable or explosive areas. Provide good ventilation.

- Installation space: To ensure ventilation and maintenance access, leave at least 1 meter of clearance on all sides so one person can pass.

- Foundation: Flat, level floor is sufficient.

Installation, Commissioning, and Training

We provide on-site installation, commissioning, and training. The user offers reasonable assistance.

- Preparation (by user)

- Provide suitable area for testing. Place the equipment in advance on a basically level surface with adequate operator space. Prepare hydraulic oil and power supply.

- Installation

- All assemblies must be installed indoors.

- Cable connections: user to provide incoming power cable and communication lines.

- Before formal commissioning, perform step-by-step inspections.

- Commissioning

- Electrical commissioning. Power-on and signal tests.

- Mechanical motion debugging.

- Full clamping and testing with a valve body.

- Training

- Technical training on system principles, process flow, and key components.

- Operator training.

- Daily maintenance training.

Other Terms

- We handle commissioning and guide installation, and provide operator training free of charge.

- Domestic warranty: 1 year. Lifetime paid service thereafter.

- Upon delivery, we provide the user manual, common troubleshooting guide, electrical schematics, and hydraulic cylinder assembly drawings.

- During detailed design and manufacturing, some minor adjustments to overall dimensions may occur.

- Payment terms: 40% deposit. Remaining balance due before shipment.

- Lubricating oil not included. Recommended grade: L-CKC-320 medium-load gear oil. Due to shipping restrictions, gear oil is supplied by the buyer.

- 46# anti-wear hydraulic oil not included. Due to shipping restrictions, hydraulic oil is supplied by the buyer.

- Lead time: 80 days.