Description

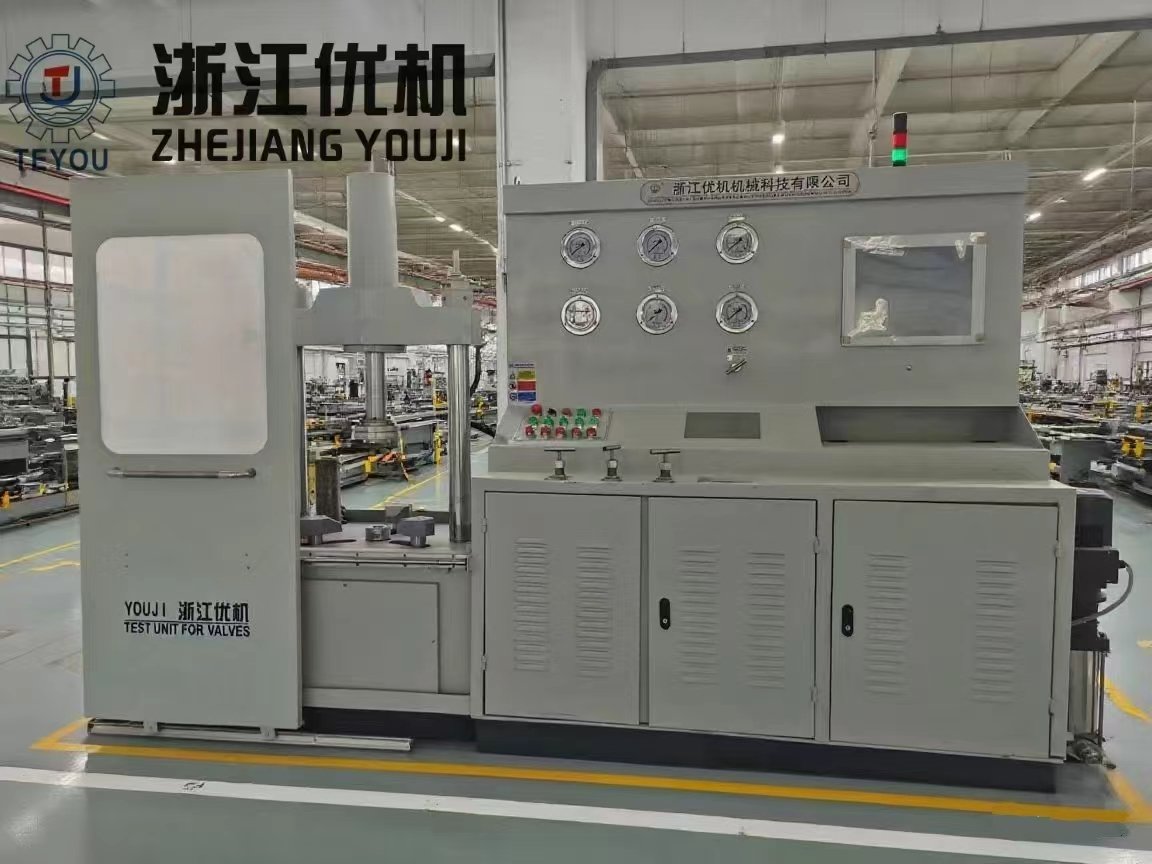

The YOUJI JLT Type Vertical Hydraulic Valve Test Bench is a new-generation, patented testing solution (Patent No. ZL2016 1 0240324.1) engineered for comprehensive valve performance evaluation. It is expertly designed to conduct precise pressure strength and sealing tests on a wide variety of flanged, welded, and threaded valves, including gate, globe, ball, and check valves.

This system is built to meet the rigorous demands of industries such as Oil & Gas, Nuclear Power, and Chemical Processing. By fully complying with international and national standards like API 598-2009, GB/T 13927-2022, and JB/T14310-2022, the JLT test bench provides verifiable, accurate, and reliable testing results for both valve manufacturers and end-users.

Key Features

- Versatile Clamping & Sealing: The system uniquely combines a hydraulic claw clamping mechanism with a top-down hydraulic pressing function. This dual-action design securely tests various valve types without inducing external stress that could affect test accuracy.

- Advanced Safety Interlocks: Operator safety is paramount. During pressure-holding cycles, all function buttons are automatically disabled if high pressure is detected in the valve cavity, preventing unsafe operations until the system is fully depressurized.

- Efficient Hydraulic System with Automatic Unloading: Features an intelligent hydraulic system that automatically switches between high-pressure and unloaded states. This significantly reduces oil temperature, extends the service life of the equipment, and conserves energy.

- User-Friendly Design: The upper crossbeam is designed to be pushed back and rotated 90 degrees, greatly simplifying the loading and unloading of heavy or awkwardly shaped valves and improving operational efficiency.

- Multi-Medium Testing Capability: Equipped with integrated high and low-pressure pumps, the system supports water, air, or kerosene as test media. A built-in reservoir allows for the recycling and storage of the test medium.

- Optional Data Management System: The unit can be upgraded with a PC-based data acquisition and management system to enable digital recording, analysis, and reporting of test results.

Technical Specifications

| Specification | Details |

|---|---|

| Model | JLT Type Vertical Hydraulic Valve Test Bench |

| Applicable Size Range | DN15 ~ DN300 (NPS 1/2” ~ 12”) |

| Pressure Range | PN1.6 ~ 48MPa (Class150 ~ 2500lb) |

| Applicable Valve Types | Gate Valves, Ball Valves, Globe Valves, Check Valves |

| Connection Types | Flanged, Welded, Threaded, Clamp |

| Drive & Control | Hydraulic Drive, PLC Control, Push-Button Control |

| Machine Body Material | Q325A Steel (or as per technical requirements) |

| Test Media | Water, Air, Kerosene (User-selectable) |

| Compliance Standards | GB/T 13927-2022, GB/T 26480-2011, API 598-2009, JB/T14310-2022 |

| Certifications | National Invention Patent (ZL2016 1 0240324.1), New Product Certificate |

| Type specification | JLT-100 | JLT-200 | JLT-300 |

|---|---|---|---|

| Nominal diameter DN (mm) | 15-100 | 50-200 | 80-300 |

| Nominal pressure PN (MPa) | 1.6-32 | 1.6-32 | 1.6-32 |

| Max. distance (mm) | ≤450 | ≤600 | ≤850 |

| Min. distance (mm) | ≤100 | ≤170 | ≤203 |

| Axial travel (mm) | ≤60 | ≤70 | ≤85 |

| Radial travel (mm) | ≤120 | ≤160 | ≤200 |

| Pressure adjustable range (MPa) | 0-6.3 | ||

| Flow (L/min) | 16 | ||

| High pressure (pressurized) (MPa) | 3.0-31.5 | ||

| Pressure for oil pump (MPa) | 0-5.0 | ||

| Voltage (V) | 380 | ||

| Frequency (Hz) | 50 | ||

| Power (kW) | 2.2 | ||

| Pole | 6 | ||

| L (mm) | 1950 | 2050 | 2630 |

| B (mm) | 1050 | ||

| H (mm) | 1900 | 2200 | 2600 |

Application Areas

- Valve Manufacturing Plants

- Oil & Gas Industry (Petroleum, Petrochemical)

- Nuclear Power Facilities

- Chemical Processing Plants

- Valve Repair and Maintenance Service Centers

Why Choose the YOUJI JLT Test Bench?

- Proven Compliance: Rigorously designed and tested to meet key global and national standards, ensuring your valve tests are accurate, repeatable, and certifiable.

- Patented Technology: Our proprietary design reflects a deep commitment to innovation, providing a functionally superior and technically advanced testing platform.

- Uncompromised Safety: With integrated features like hydraulic auto-unloading and pressure safety interlocks, we prioritize operator well-being and equipment protection.

- Built for Durability: The automatic unloading system not only saves energy but also reduces wear on hydraulic components, ensuring a longer service life and lower total cost of ownership.

Support & Service

YOUJI is committed to providing comprehensive support for your investment. Our services include:

- Installation & Commissioning: We provide expert guidance for equipment setup, including leveling and foundation requirements, to ensure optimal performance from day one.

- Operational Training: Our team will train your operators on proper usage, safety protocols, and routine maintenance procedures.

- After-Sales Support: We provide detailed documentation, including operating manuals and pressure requirement charts. Our technical team is available to assist with troubleshooting and maintenance questions, ensuring your test bench remains in peak condition.

Installation dimensions

Installation dimensions

Performance Graph

Performance Graph