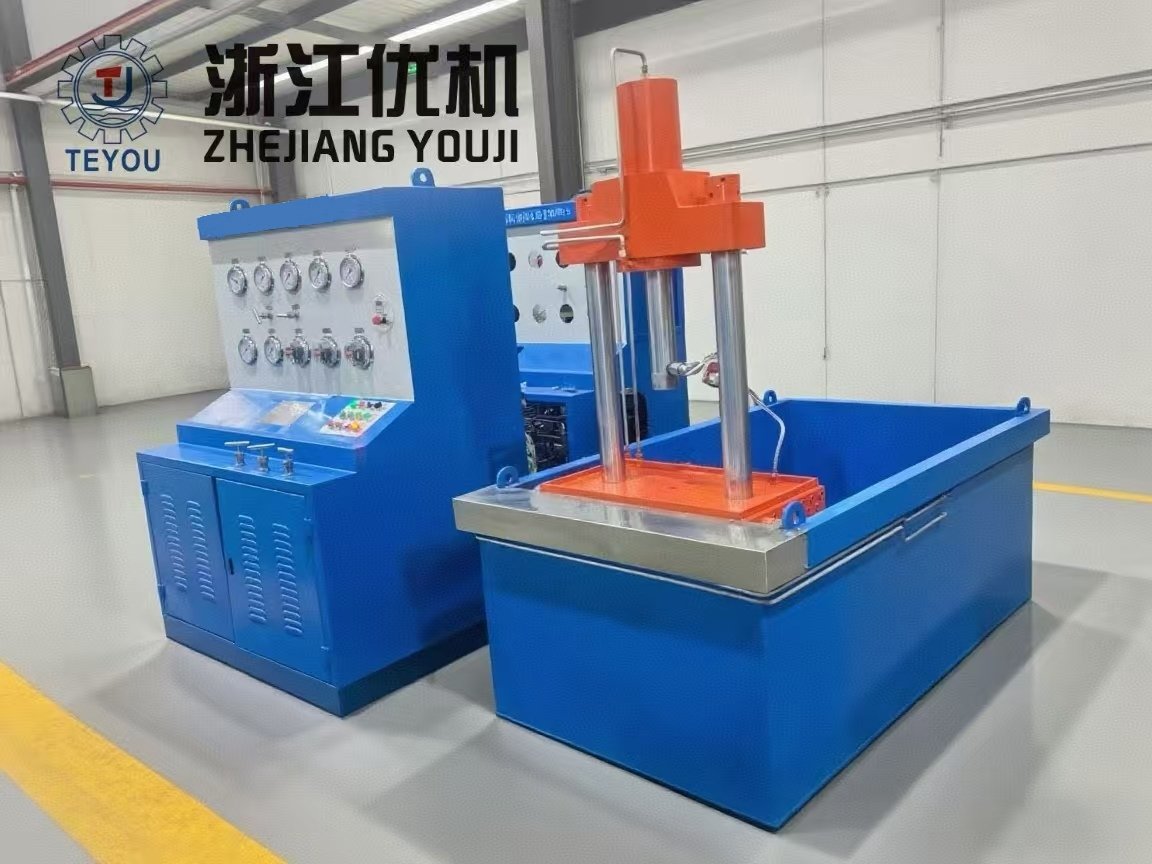

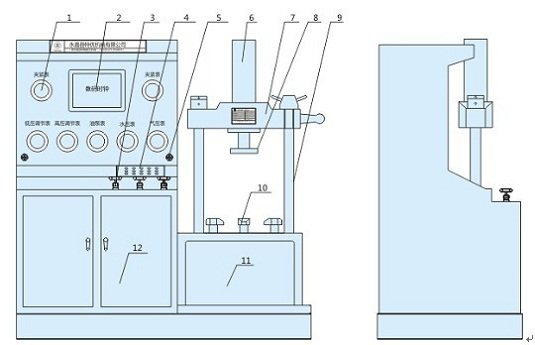

The JLT-QS diving vertical hydraulic testing bench is a compact, fully integrated solution for pressure strength and housing integrity tests on welded and flanged flowmeter bodies and valve housings. Designed from YOUJI’s years of fluid test-system engineering, it adopts an unloading + pressure-holding hydraulic circuit that keeps the oil temperature rise below $35^\circ C$ during continuous 50-hour operation, reducing energy consumption and extending component life. The bench supports water, air, and oil as test media and delivers stable, accurate, and repeatable results for production and maintenance environments.

Key Features

- Diving vertical (top-loading) structure: compact footprint, easy operation, high stability.

- Unloading + pressure-holding hydraulic circuit: keeps oil temperature rise $\le 35^\circ C$ after 50 h continuous run.

- Multi-medium testing: supports water / air / oil; high and low pressure pump configuration.

- High-sensitivity control: remote pressure regulation with booster; precise actuator positioning.

- Safety interlock: during water/air hold periods, actuators remain locked until pressure is fully released.

- Rugged piping: galvanized, acid-washed high-pressure lines minimize metallic residue and enhance pressure tolerance.

Compliance & Standards

- GB/T 13927-2008 General Valve Pressure Testing

- ZBJ 16006-90 Valve Inspection & Testing

- API 598, API 6D

System Overview

Hydraulic System

- Unloading + pressure-holding loop for energy efficiency and extended seal life (imported polyurethane seals).

- Hydraulic station integrated with the main frame; galvanized, flushed pipework for reliability.

- Remote pressure regulation at the console, paired with a booster unit.

- Actuation and test-media pressurization via panel buttons (Schneider) and a custom high‑pressure valve group.

- Core hydraulic components adopt Shanghai Huada; pump motor adopts Siemens.

Test Medium Input & Control

- Reserved low-pressure air interface: $M18 \times 1.5$ flat-head (air source supplied by user).

- Equipped with low- and high-pressure water pumps (low-pressure water pump by Shanghai Juyi).

- High-pressure pump selectable: air-driven booster or hydraulic plunger pump.

- Six needle valves for media control; pressure resistance up to $70 \text{ MPa}$.

- Galvanized, acid-washed high-pressure oil/water lines provide superior pressure tolerance and cleanliness.

- Safety logic: under any elevated internal pressure during hold, panel buttons remain inactive until pressure is fully released.

Electrical & Instrumentation

- Electrical design meets operational control requirements with reliable components (CHNT).

- All operations centralized on the front control panel for convenience.

- Pressure gauges from Zhejiang Reierda for accuracy and durability.

Functions

- Pressure strength testing for flowmeter housings (body testing).

- Optional pneumatic tests if user supplies an air source.

Application Areas

- Flowmeter manufacturing and quality inspection (welded / flanged bodies)

- Valve housing pressure tests in Oil & Gas, Petrochemical, and Power sectors

- Production lines and service workshops requiring precise, repeatable pressure testing

Technical Specifications

| Item | Specification | Notes |

|---|---|---|

| Test Media | Water / Air / Oil | Multi-medium support |

| Air Interface | $M18 \times 1.5$ (flat-head) | User-supplied air source |

| Hydraulic Circuit | Unloading + pressure-holding | Energy-saving, extends seal life |

| Continuous Operation | 50 hours | Oil temperature rise $\le 35^\circ C$ |

| Media Control Valves | 6 needle valves | Pressure resistance up to $70 \text{ MPa}$ |

| Piping | Galvanized & acid-washed high-pressure lines | High pressure tolerance; reduced residue |

| Low-Pressure Water Pump | Shanghai Juyi | Factory-configured |

| High-Pressure Pump | Air-driven booster or hydraulic plunger | Select per test range |

| Electrical Components | CHNT (panel & control) | Schneider buttons on panel |

| Pressure Gauges | Zhejiang Reierda | Analog readout |

| Hydraulic Components | Shanghai Huada; seals (PU) | Siemens motor for pump |

| Test Standards | GB/T 13927-2008, ZBJ 16006-90 | API 598, API 6D |

Competitive Advantages

- Stable, precise pressure control with high repeatability.

- Lower energy consumption and extended component lifetime.

- Enhanced safety via pressure-hold interlock logic.

- Compact vertical layout for efficient workspace utilization.

Support & Service

- On-site installation and operator training

- Process setup and pressure range calibration

- Spare parts supply and lifecycle technical support