Description

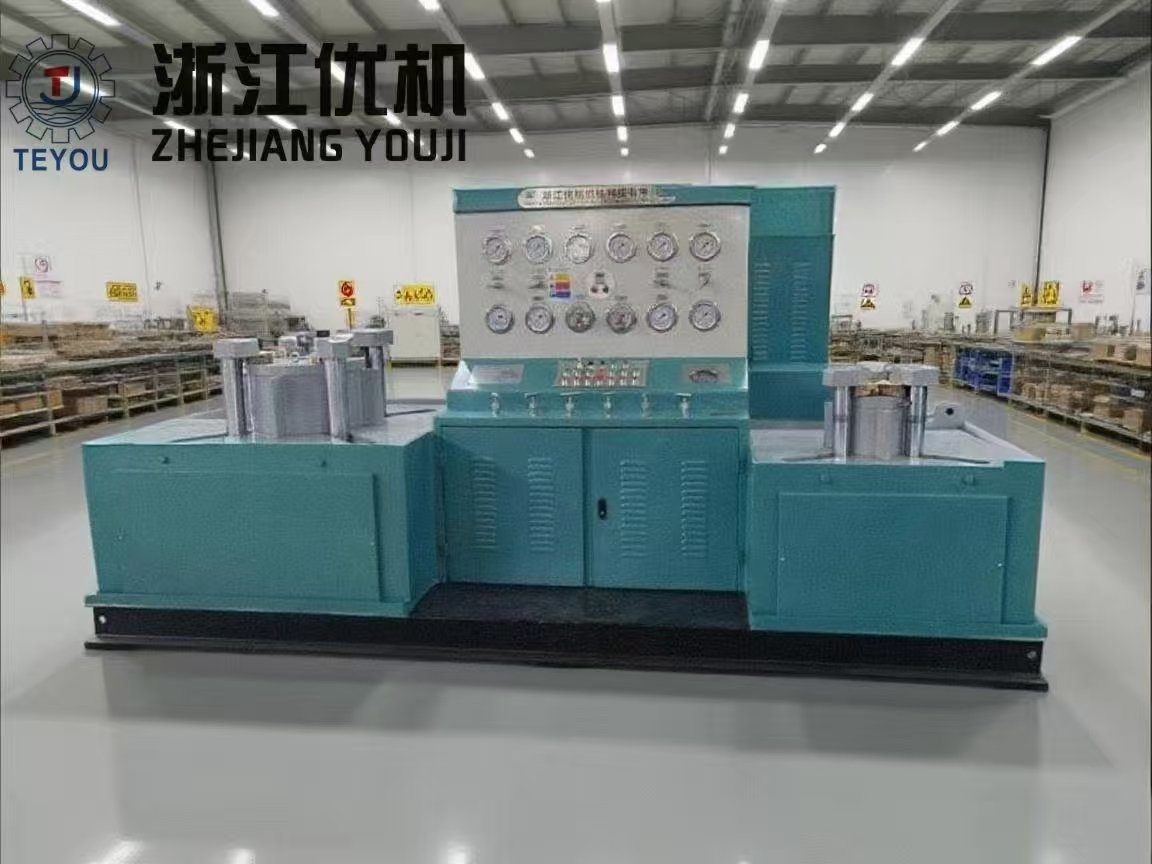

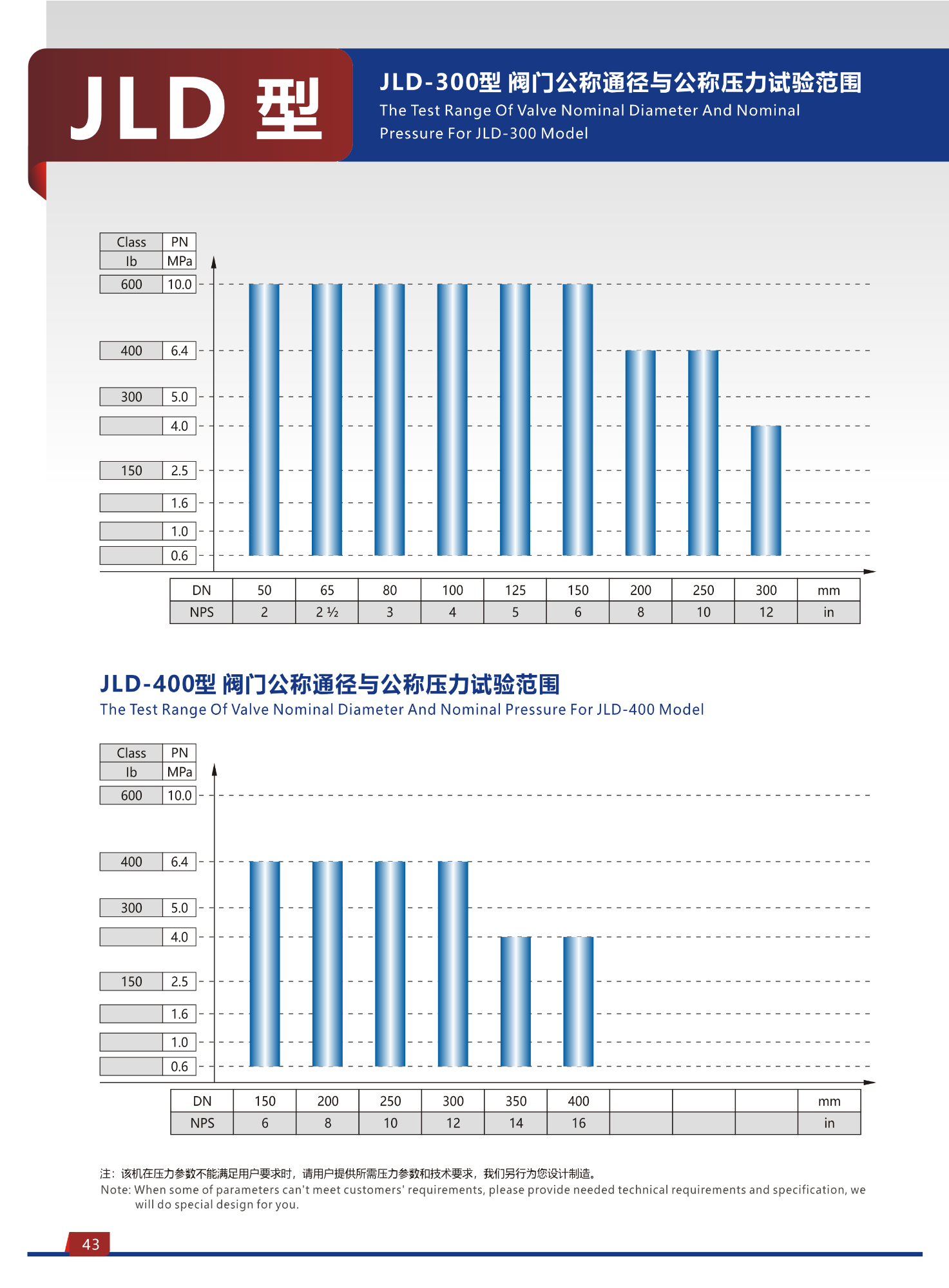

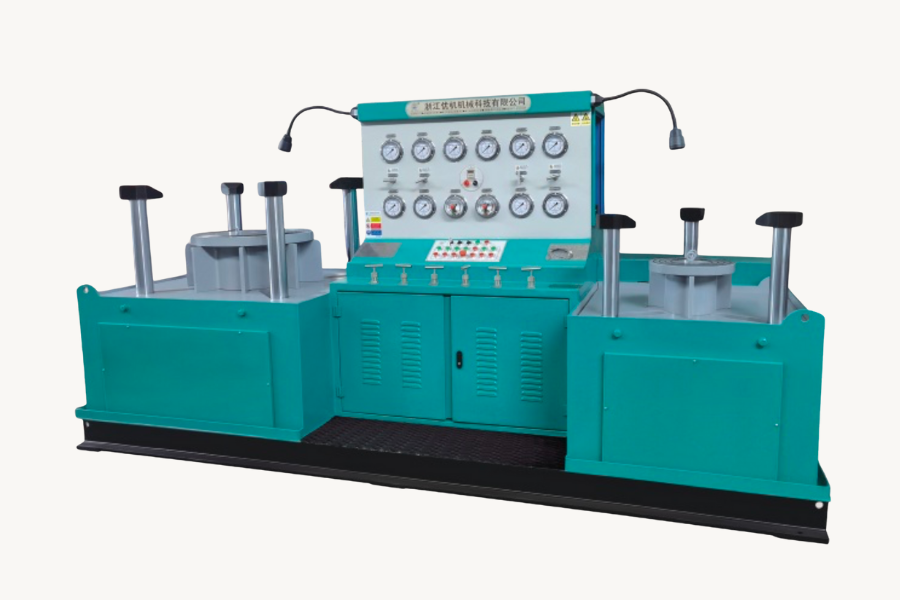

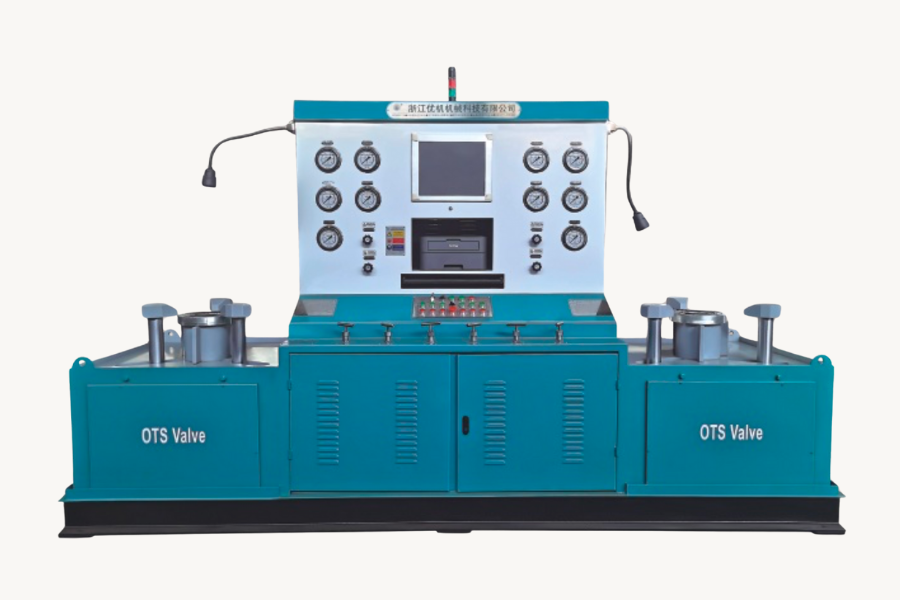

The JLD Series Hydraulic Test Bench is a purpose-built solution for the comprehensive testing of butterfly valves. Going beyond standard pressure tests, the JLD series is uniquely equipped to perform actuator torque testing and 90-degree opening/closing cycle tests, making it an indispensable tool for butterfly valve manufacturers and valve automation centers.

Its patented synchronous clamping system uses powerful hydraulic jaws to securely hold both flanged and wafer-type butterfly valves, ensuring accurate and repeatable results without inducing stress on the valve body. This all-in-one machine provides a complete platform for verifying the performance, integrity, and operational torque of your butterfly valves.

Key Features

- Specialized Butterfly Valve Testing: Uniquely designed to conduct not only strength and seal tests but also functional tests, including electric actuator torque measurement and 90° opening/closing cycle analysis.

- Versatile Synchronous Clamping: The advanced hydraulic jaw system can clamp standard flanged butterfly valves and also extend to securely grip the body of wafer-type (non-flanged) valves, offering maximum flexibility.

- Patented & Certified Design: The innovative clamping technology is protected by a national patent (No. ZL201610240324.1) and the entire system is fully compliant with GB/T 13927-2022, GB/T 26480-2011, JB/T 14310-2022, and API 598-2009.

- Integrated High & Low-Pressure Pumps: The test bench includes a self-contained pressure supply system with high-pressure and high-flow low-pressure pumps, with a circulating reservoir for the test medium.

- Energy-Efficient Hydraulics: Features an automatic hydraulic unloading system that intelligently switches between high-pressure and unloaded states, effectively reducing oil temperature, extending component life, and lowering power consumption.

- Advanced Safety Interlock: To guarantee operator safety, all control buttons are disabled if the system detects residual pressure in the valve. The system must be fully depressurized before a new cycle can begin.

- Optional PC Data Management: The system can be upgraded with a computer-based control and data acquisition system for digital test monitoring, data storage, and report generation.

Technical Specifications

| Specification | Value |

|---|---|

| Model | JLD Series |

| Applicable Diameter | DN50 – DN2400 / NPS 2” – 96” |

| Pressure Range | PN1.6 – 48 MPa / Class 150 – 2500 lb |

| Primary Valve Types | Butterfly Valves (Flanged & Wafer Type) |

| Other Applicable Valves | Slab Gate Valves, Knife Gate Valves |

| Special Test Capabilities | Actuator Torque Measurement, 90° Opening/Closing Cycle Test |

| Clamping Method | Synchronous Hydraulic Jaw Clamping |

| Control System | Hydraulic Drive, PLC Control, Push-Button Operation |

| Standards | GB/T 13927-2022, GB/T 26480-2011, JB/T 14310-2022, API 598-2009 |

| Patent | ZL2016 1 0240324.1 |

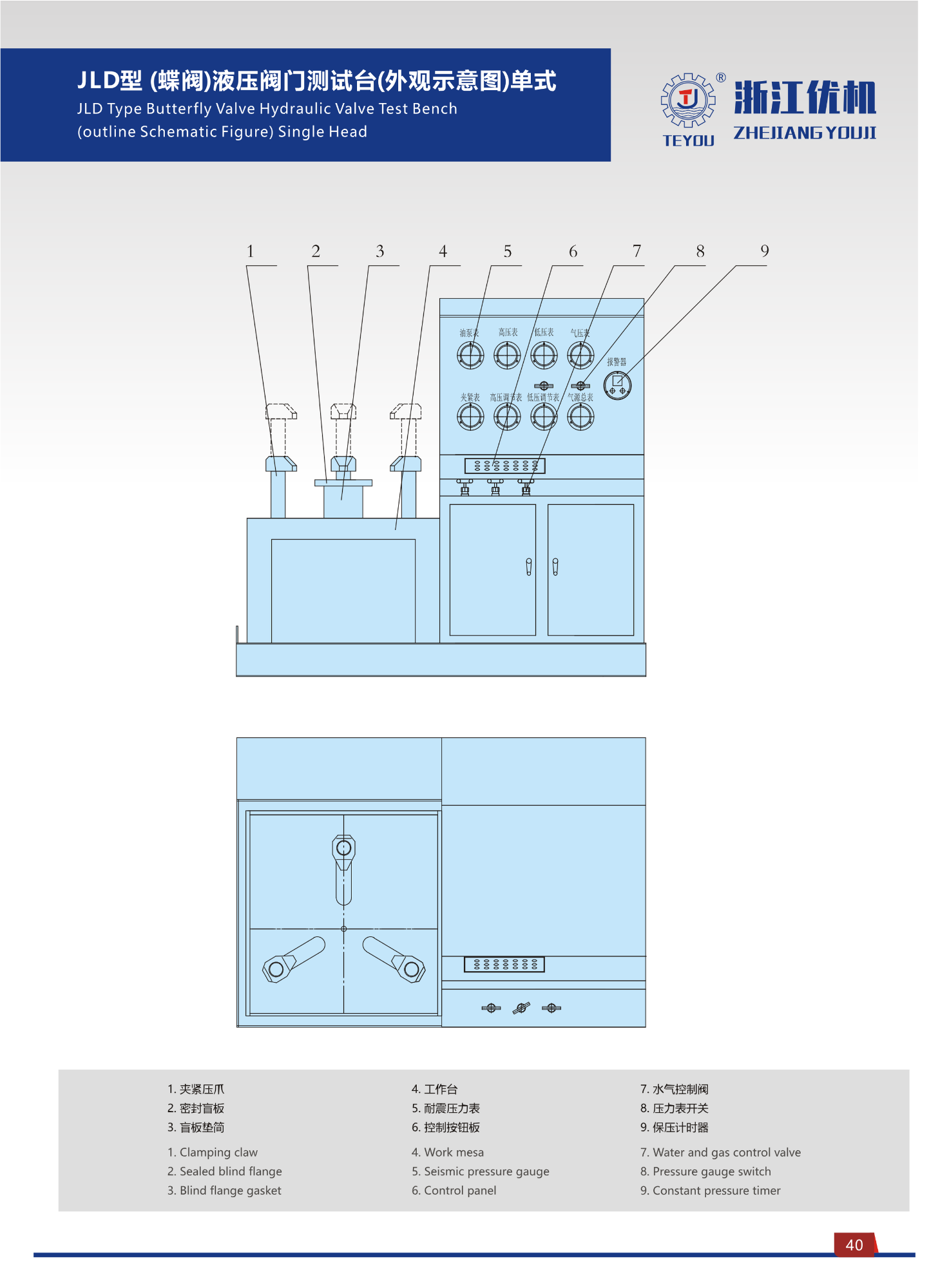

JLD Type(Single head) main technical parameter & specification

| Type | JLD-300 | JLD-600 | JLD-800 | JLD-1000 | JLD-1200 | JLD-1400 | JLD-1600 | JLD-2000 |

|---|---|---|---|---|---|---|---|---|

| Specification | DN50-300 | DN300-600 | DN400-800 | DN500-1000 | DN700-1200 | DN800-1400 | DN900-1600 | DN1200-2000 |

| Voltage (V) | 380 | |||||||

| Frequency (Hz) | 50 | |||||||

| Power (KW) | 2.2 | 3.0 | 3.0 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Grade (P) | 6 | |||||||

| Highest work pressure of oil pump (MPa) | 0-6.3 | |||||||

| Adjustable oil pressure in the cylinder (MPa) | 31.5 | |||||||

| The valve maximum drift diameter pressure (MPa) | 4.0 | 2.5 | 2.5 | 2.5 | 2.5 | 1.6 | 1.6 | 1.6 |

| Effective biggest radial (mm) | 520 | 850 | 1080 | 1320 | 1530 | 1690 | 2050 | 2400 |

| Effective biggest axial (mm) | 370 | 620 | 880 | 1030 | 1090 | 1150 | 1200 | 1260 |

| Outlet pressure of a water pump Max. (MPa) | 10.0 | |||||||

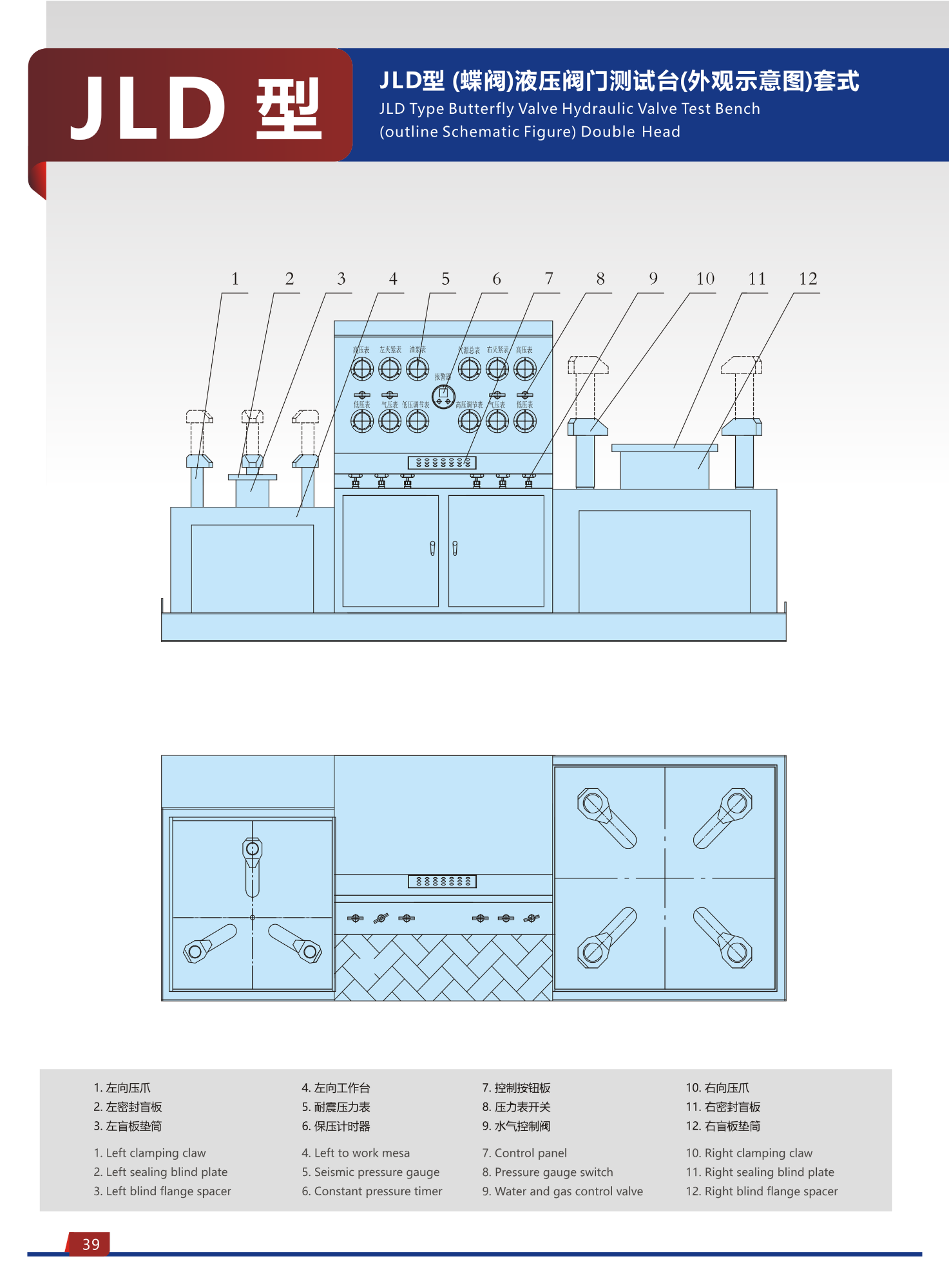

JLD Type (double Head) Main Technical Parameter & Specification

| Type | JLD-600 | JLD-800 | JLD-1000 | JLD-1200 | JLD-1400 | JLD-1600 | JLD-2000 |

|---|---|---|---|---|---|---|---|

| Specification | DN50-600 | DN200-800 | DN250-1000 | DN300-1200 | DN400-1400 | DN400-1600 | DN600-2000 |

| Voltage (V) | 380 | ||||||

| Frequency (Hz) | 50 | ||||||

| Power (KW) | 3.0 | 3.0 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Grade (P) | 6 | ||||||

| Highest work pressure of oil pump (MPa) | 0-6.3 | ||||||

| Adjustable oil pressure in the cylinder (MPa) | 31.5 | ||||||

| The valve maximum drift diameter pressure (MPa) | 2.5 | 2.5 | 2.5 | 2.5 | 1.6 | 1.6 | 1.6 |

| Effective biggest radial (mm) | 520-850 | 690-1080 | 760-1320 | 810-1530 | 1080-1690 | 1080-2050 | 1530-2400 |

| Effective biggest axial (mm) | 370-620 | 550-880 | 610-1030 | 490-1090 | 880-1150 | 880-1200 | 1090-1260 |

| Outlet pressure of a water pump Max. (MPa) | 10.0 | ||||||

Application Areas

The JLD Butterfly Valve Test Bench is the premier choice for quality assurance across a range of industries:

- Butterfly Valve Manufacturing

- Valve Automation Centers

- Water Treatment & Distribution

- HVAC & District Energy Systems

- Chemical Processing

- Power Generation

- Valve Repair & Maintenance (MRO)

Competitive Advantages

- All-in-One Butterfly Valve Solution: Save time, space, and investment by testing pressure, sealing, and actuator performance on a single, integrated machine.

- Adaptable Clamping for All Types: The ability to test both flanged and wafer-type valves without complex adapters or retooling significantly improves workflow efficiency.

- Large Diameter Capability: Confidently test a massive range of sizes, from standard to very large butterfly valves up to DN2400 / 96 inches.

- Patented & Certified: Our patented design and adherence to global standards like API 598 provide you and your customers with the highest level of confidence in your product quality.

Support & Service

is your partner in precision testing. We provide comprehensive support including:

- On-site Installation and Commissioning

- Detailed Operator and Maintenance Training

- Responsive After-Sales Technical Support

- A complete inventory of spare and wear parts.