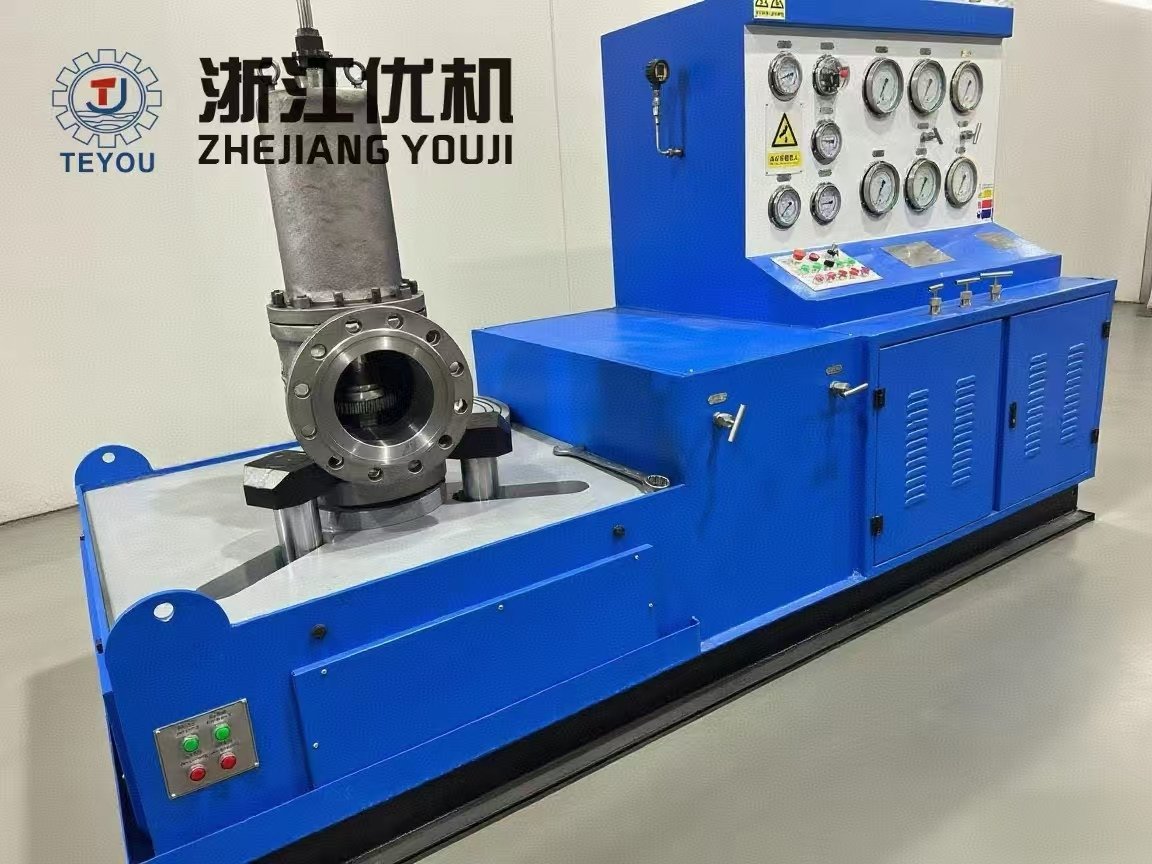

The YOUJI JLA Type Safety Valve Performance Test Bench is a specialized and patented calibration system (Patent No. ZL2016 1 0240324.1) engineered exclusively for testing and certifying flanged safety valves. This advanced bench is designed to accurately measure all critical performance metrics, including set pressure, opening pressure, reseating pressure, and seat tightness, ensuring your critical safety devices function flawlessly and comply with all regulatory standards.

A key innovation of the JLA series is its integrated gas booster system, which eliminates the need for expensive and hazardous high-pressure gas storage tanks. By connecting to a standard 0.6 MPa air compressor, the system can automatically generate test pressures up to 48 MPa. This makes the JLA bench a safer, more convenient, and more cost-effective solution for valve service shops, manufacturing facilities, and processing plants.

Key Features

- Specialized Safety Valve Calibration: Purpose-built to perform all essential safety valve tests, including set pressure (popping pressure), reseat pressure, and seat leakage (tightness) tests with high precision.

- Integrated Gas Booster System: An innovative internal system automatically boosts low-pressure shop air (or nitrogen) to the required high pressure for testing, eliminating the need for bulky, high-pressure gas cylinders and improving workplace safety.

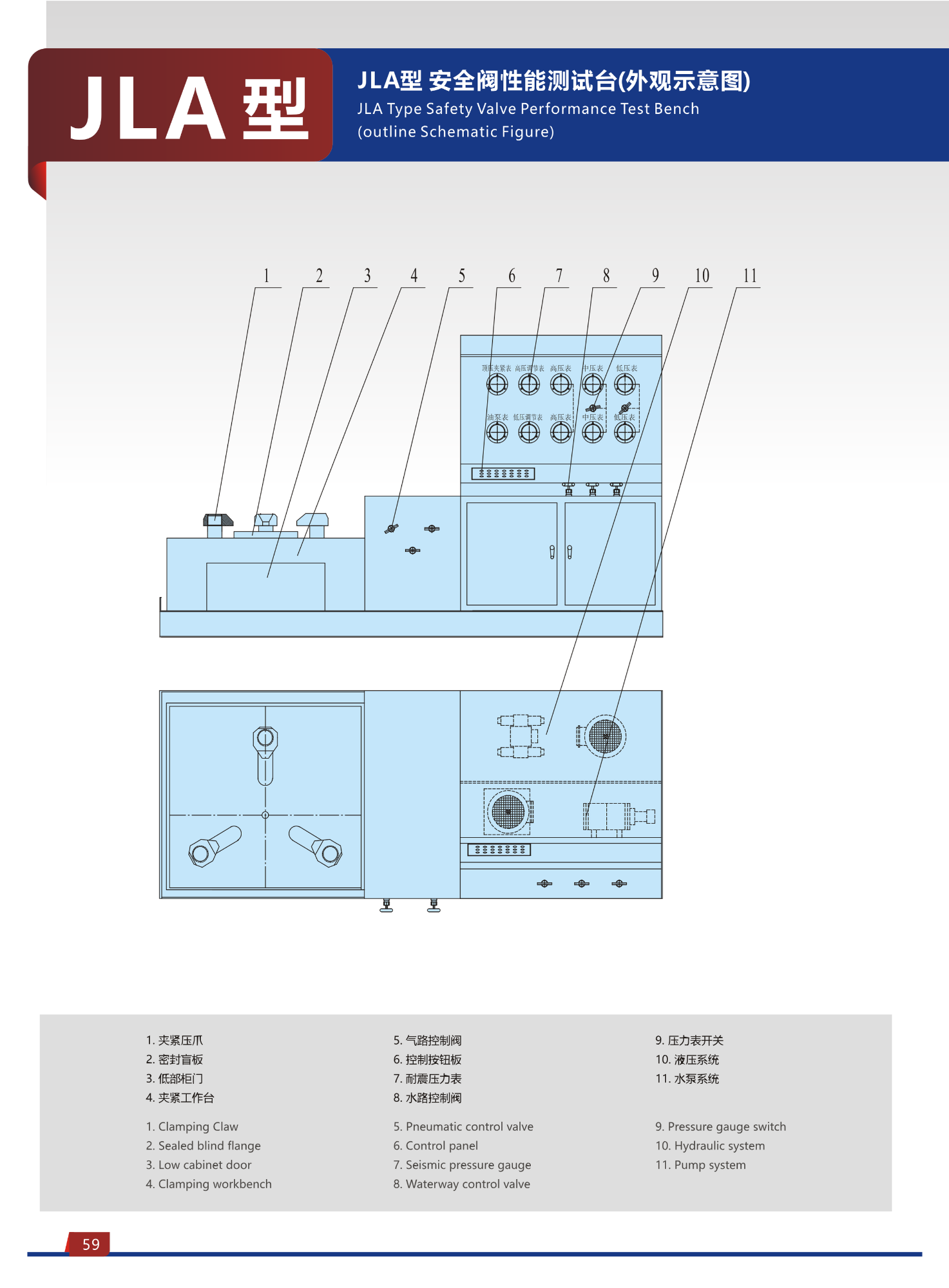

- Non-Intrusive Clamping: The system utilizes hydraulic claws that clamp the back of the valve flange, sealing on the flange face. This method secures the valve without applying external forces to the valve body, which could otherwise skew test results.

- Efficient Hydraulic System: Features YOUJI’s signature automatic hydraulic unloading system. This reduces oil temperature, extends the life of hydraulic components, and significantly lowers energy consumption during operation.

- Dual Control Modes: Offers both automatic and manual control over the gas booster system, providing operators with the flexibility to conduct tests according to specific procedures or to observe valve behavior closely.

- Optional PC-Based Data Management: The bench can be equipped with a computer-based data acquisition and management system for generating digital test reports, certifying performance, and maintaining historical records.

Technical Specifications

| Specification | Details |

|---|---|

| Model | JLA Type Safety Valve Performance Test Bench |

| Applicable Valve Type | Flanged Safety Valves / Pressure Safety Valves (PSV) |

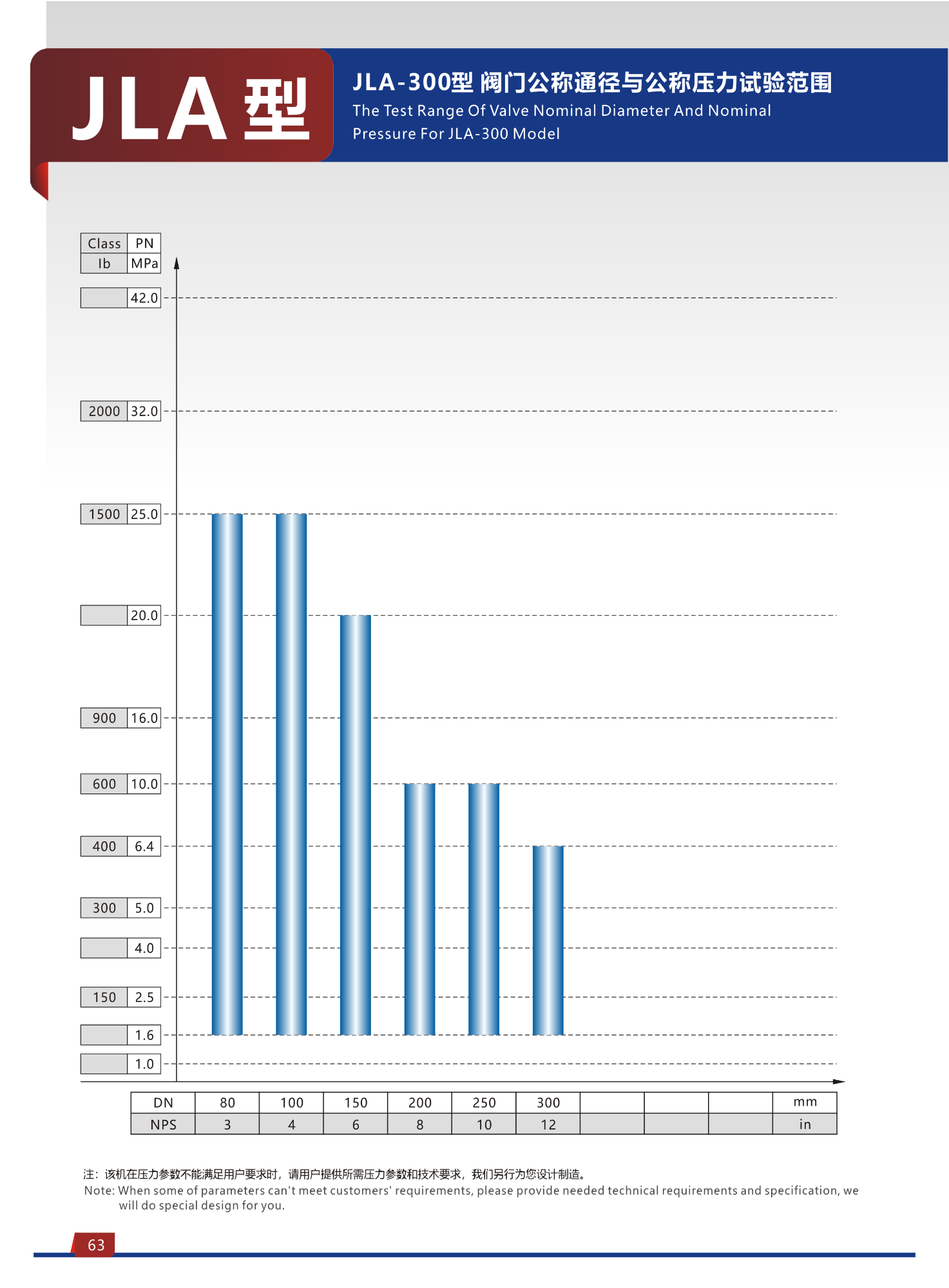

| Applicable Size Range | DN15 ~ DN300 (NPS 1” ~ 12”) |

| Pressure Range | PN1.6 ~ 48MPa (Class150 ~ 2500lb) |

| Test Media | Air, Nitrogen |

| Clamping Mechanism | Hydraulic Back-of-Flange Jaw Clamping |

| Drive & Control | Hydraulic Drive, PLC Control, Push-Button Control |

| Compliance Standards | GB/T 13927, ZBJl6006-90, and other relevant standards |

| Certifications | National Invention Patent (ZL2016 1 0240324.1), New Product Certificate |

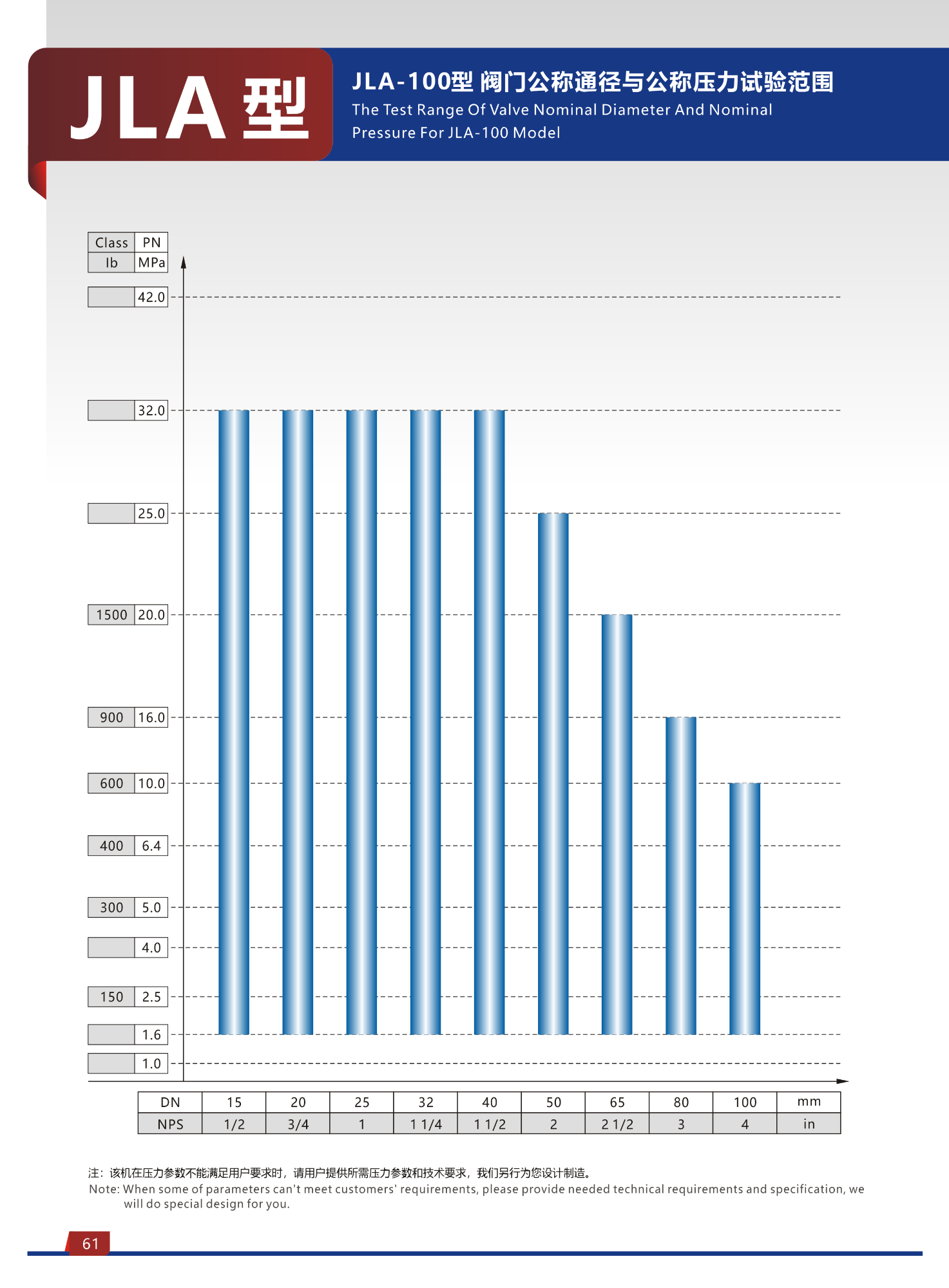

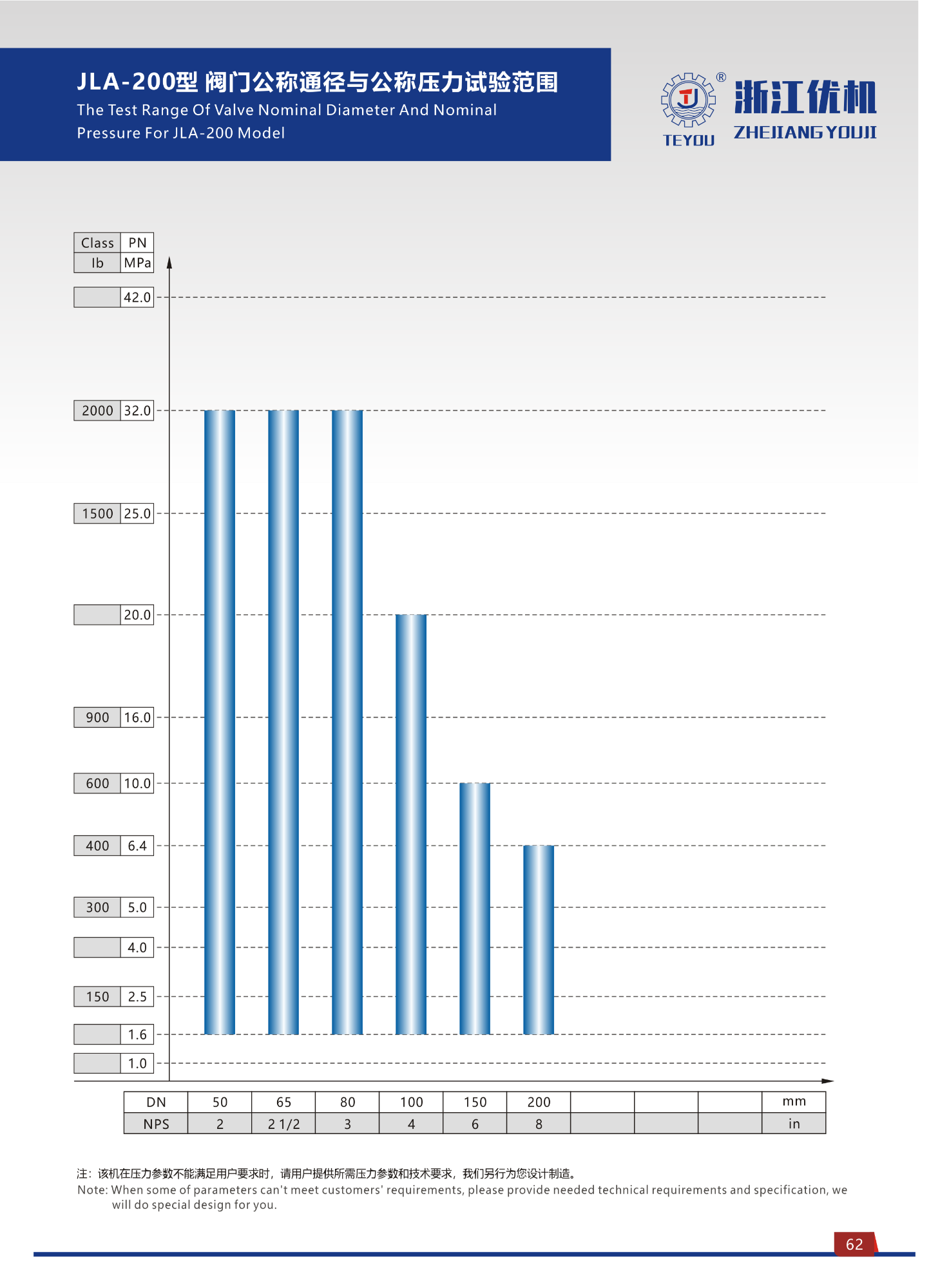

| 型号规格 Type specification | JLA-100 | JLA-200 | JLA-300 |

|---|---|---|---|

| 被试阀门公称通径 Nominal diameter of tested valve | DN15–100 | DN50–200 | DN80–300 |

| 被试阀门法兰Φ Tested valve flange | 最小 Smallest: 95 | 最小 Smallest: 160 | 最小 Smallest: 195 |

| 最大 Biggest: 290 | 最大 Biggest: 420 | 最大 Biggest: 580 | |

| 压紧油缸最高压力 Highest pressure of clamp cylinder | 31.5 | 31.5 | 31.5 |

| 功率 kW Power | 2.2 | 2.2 | 2.2 |

| 极数 P Pole | 6 | 6 | 6 |

| 电压 V Voltage | 380 | 380 | 380 |

| 频率 Hz Frequency | 50 | 50 | 50 |

Application Areas

- Safety Valve Manufacturers

- PSV Calibration and Repair Workshops

- Oil Refineries and Petrochemical Plants

- Power Generation Facilities (Fossil & Nuclear)

- Chemical Processing Plants

- Third-Party Inspection and Certification Bodies

Why Choose the YOUJI JLA Test Bench?

- Unmatched Convenience & Safety: The integrated gas booster system is a game-changer, simplifying installation and operation while removing the hazards associated with high-pressure gas storage.

- Guaranteed Accuracy: Our non-intrusive clamping and precision pressure controls ensure that test results are reliable, repeatable, and reflect the true performance of the valve.

- Patented, Proven Design: As a leader in valve testing technology, our patented JLA design is a result of years of research and development, offering proven performance.

- Built for Industrial Use: With robust construction and an energy-efficient hydraulic system, the JLA bench is designed for durability and a low total cost of ownership.

Support & Service

YOUJI provides comprehensive support, including safe installation guidelines (maintaining proper distance between the control console and test bench), operator training on all functions and safety protocols, and long-term after-sales service for maintenance and technical inquiries.

Safety Valve Test Bench/Safety Valve Testing Bench/Safety Valve Testing Machine/Safety Valve Test Stand