Applications and Uses of Plug Valves

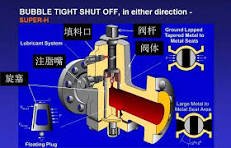

A plug valve is a type of valve that uses a rotating plug to control flow and shut-off. Its core advantages are fast opening and closing speed, low flow resistance due to a straight-through flow path, and a simple and wear-resistant structure. Its disadvantages include sealing performance being significantly affected by plug wear, and higher […]