API 598: Detailed Explanation of the Valve Inspection and Testing Standard

API 598 is a valve inspection and pressure testing standard developed by the American Petroleum Institute (API) and applies to industrial valves (such as gate valves, globe valves, ball valves, and check valves). Its core purpose is to verify valve integrity and leak tightness through shell and seal tests.

Test Types and Examples

1. Shell Test

Purpose: To verify the strength and leakage of pressure-bearing components such as the valve body and bonnet.

Test Method:

The valve is in the half-open position (the disc/ball does not contact the sealing surface).

Inject water or air into the valve cavity and pressurize to 1.5 times the maximum working pressure (for example, 450 psi for a design pressure of 300 psi).

Dwell Time: ≥60 seconds (DN ≤ 100 mm) or ≥120 seconds (DN > 100 mm).

Acceptance Criteria: No visible leakage, deformation, or sweating (surface seepage) on the valve body. Example:

A DN80 (3-inch) gate valve has a design pressure of 16 bar (232 psi).

Test pressure: 16 × 1.5 = 24 bar (348 psi).

Dwell time: 60 seconds.

Result: Acceptable if there is no leakage or permanent deformation in the valve body.

2. Backseat Test

Purpose: Verify the sealing performance between the valve stem and the bonnet (only for valves with a “backseat” design).

Test method:

Fully open the valve to press the backseat seal against the bonnet.

Apply pressure to 1.1 times the maximum working pressure (e.g., 330 psi for a 300 psi valve).

Dwell time: Same as for the shell test.

Acceptance criterion: No leakage from the stem packing.

Example:

A globe valve with a backseat has a design pressure of 20 bar (290 psi).

Test pressure: 20 × 1.1 = 22 bar (319 psi).

Result: Acceptable if no bubbles or droplets seep out of the connection between the valve stem and the valve cover.

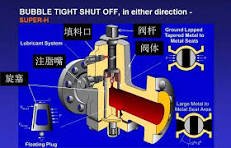

3. Seat Test

Purpose: To check the tightness of the valve seat and the opening and closing components (valve disc/ball) when the valve is closed.

Test Method:

High-pressure test:

With the valve fully closed, pressurize one end to 1.1 times the maximum working pressure (water or air).

Check for leakage on the other end (bidirectional sealing valves require bidirectional testing).

Low-pressure test:

Use air or inert gas (pressure 0.5–0.7 bar), immerse in water, and observe for bubbles.

Acceptance criteria:

Liquid test: No visible droplets (zero leakage).

Gas test: Leakage ≤ allowable value (e.g., ≤ 20 bubbles/minute for a DN50 valve). Example:

One ball valve (DN100, design pressure 10 bar):

High-pressure seal test: Pressurize to 11 bar (water), maintain pressure for 120 seconds, no water drops at the outlet.

Low-pressure seal test: Pressurize to 0.6 bar (air), immerse in water, and produce ≤5 bubbles/minute (in compliance with standards). Key Process Summary

Test Steps

Media

Pressure

Dwell Time

Test Points

Shell Test

Water/Air

1.5 x Design Pressure

≥60–120 seconds

Body and Bonnet

Upper Seal Test

Water/Air

1.1 x Design Pressure

≥60–120 seconds

Stem Packing

High-Pressure Seat Test

Water

1.1 x Design Pressure

≥60–120 seconds

Other Side of Seat

Low-Pressure Seat Test

Air

0.5–0.7 bar

≥60 seconds

Number of Bubbles

Special Requirements

Check Valves: Only shell test and one-way seal test are required (pressurization in the direction of medium flow).

Butterfly Valves: Shaft seal test is required (similar to upper seal test).

Allowable Leakage Rate: During gas testing, the leakage rate of metal-sealed valves must comply with API 598 Table 6 (e.g., ≤25 bubbles/minute for valves DN ≤ 100 mm). Practical Application Scenario

A refinery purchased a batch of gate valves (API 600 standard). The manufacturer conducted the following tests according to API 598:

Shell test: 300 psi water pressure for 60 seconds, no body leakage.

Top seal test: 330 psi water pressure, no stem leakage.

Seat seal test:

High-pressure water test (330 psi): No water dripping at the outlet.

Low-pressure air test (0.6 bar): ≤15 bubbles/minute after immersion in water.

Result: The valves were labeled API 598-compliant and released for service.

Note: API 598 is a minimum standard. Severe operating conditions (such as high temperatures and corrosive media) require additional testing (e.g., API 6D for pipeline valves).

API 598:Valve Inspection and Testing Standard、Valve pressure test requirements,valve testing api 598