Butterfly Valve Pressure Testing Machine Technical Overview(Butterfly Valve Test Bench Technology Overview)

Model: JLD Series (Flanged/Wafer Type Butterfly Valve Dedicated)

Functional Positioning: A fully automatic sealing and strength testing platform specifically designed for butterfly valves, covering factory testing, type testing, and re-inspection needs for butterfly valves from low to medium-high pressure (PN10~PN40). Supports soft-seal/metal-seal butterfly valves, compatible with mainstream connection types such as wafer, flange, and double-flange.

Five Core Technical Features

1. Intelligent Adaptive Clamping System

Three-point floating sealing structure: Hydraulically driven upper sealing disc automatically compensates for butterfly valve flange surface parallelism deviation (≤±2°), avoiding sealing failure caused by valve body deformation.

Constant Pressure Closed-Loop Control: Pressure sensor provides real-time feedback of sealing surface clamping force; PID algorithm dynamically adjusts oil pressure with an accuracy of ±0.5MPa, preventing overpressure damage to the valve body.

2. Dual-Media Testing Capability

Test Type

Media

Pressure Range

Application Scenarios

Shell Test

Water (optional rust inhibitor)

1.5×PN (Max 6.4MPa)

Valve Body Strength Verification

Sealing Test

Air/Nitrogen

1.1×PN (Max 4.4MPa)

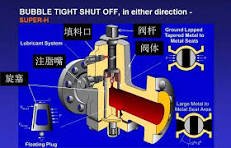

Low-Pressure Bubble Leak Detection (Sensitivity 0.1mm)

Dual-Truncation Test

Water + Air Combination

Step-by-Step Pressure Increase

API 598 Standard Dual-Truncation Seal Certification

3. High-Efficiency Integrated Testing Process

Hydraulic

Pneumatic

Valve Body Clamping

Automatic Water/Air Injection

Pressure Mode Selection

Hydraulic Test: 0→1.5PN, stabilizing for 5 min

Air Tightness Test: 0→1.1PN, holding pressure for 3 min + soap solution leak detection

Automatic Pressure Relief/Drainage

Generate PDF Report

4. Safety and Reliability Design

Dual Redundancy Protection: Mechanical safety valve (relief value 110%PN) + Electrical overpressure emergency stop, compliant with ISO 5208 safety standards.

Splash-proof structure: The test chamber uses a 304 stainless steel sealed cover (pressure resistance 10MPa), and the viewing window is equipped with tempered glass (thickness 12mm). 5. Intelligent Data Management

Industrial IoT Architecture:

4G module uploads test data to the cloud (SQL database)

Barcode scanner associated with valve ID, tracing test records (pressure curve/leakage rate/operator)

Real-time push notifications of abnormal alarms via WeChat (e.g., pressure drop > 5%)

Technical Parameter Comparison

Project

Traditional Pressure Testing Bench

JLD Butterfly Valve Pressure Testing Machine

Single Valve Test Cycle

≥15min

≤7min (air tightness test only 3min)

Maximum Valve Diameter

DN50-DN600/DN50-DN800/DN300-DN1200/

DN1200-DN2400 (customized hydraulic expansion)

Leakage Detection Accuracy

Visual observation of bubbles

Electronic flow meter (0.01L/min)

Energy Consumption

15kW·h/valve

8.5kW·h/valve (frequency converter control)

Industry Application Scenarios

Manufacturing: Batch factory testing of butterfly valves (supports 8-hour continuous testing ≥50 units)

Power Plant Maintenance: Re-inspection of flue butterfly valves after online maintenance (with mobile units)

Certification Laboratory: Compliant with API 609/EN 593/AWWA C504 Certification Requirements

Note: Custom upgrades are supported, including ultra-low temperature testing (-196°C liquid nitrogen environment), high-pressure gas sealing (PN100), and other special operating conditions.

This equipment’s modular design reduces maintenance costs (MTBF of key components > 100,000 cycles), significantly improves butterfly valve inspection efficiency and data reliability, and helps companies obtain TSG D7002 pressure piping component certification.